As someone who's worked with chiffon for over twenty years—from luxury evening wear to theatrical costumes—I understand the frustration when delicate fabrics fail at the seams. Just last month, a New York designer showed me a $800 retail blouse that developed seam tears after two wears. The problem wasn't the fabric's beauty but its technical specifications—or lack thereof. Lightweight chiffon presents unique challenges because the very properties that make it desirable (sheer drape, fluid movement) work against its durability.

Specifying tear strength and seam slippage for chiffon requires understanding that traditional fabric testing protocols often need modification for these delicate materials. The standard 5cm strip test for tear strength can literally destroy some chiffons before yielding meaningful data. Meanwhile, seam slippage in these open-weave constructions can occur at surprisingly low loads, leaving garments structurally compromised even when the fabric itself remains intact.

Proper specification involves four critical aspects: understanding the relationship between fiber content and fabric structure, establishing realistic performance thresholds for different applications, selecting appropriate testing methodologies, and implementing construction techniques that enhance durability without compromising aesthetics. Let me share what we've learned developing chiffon fabrics for clients ranging from haute couture houses to fast-fashion retailers.

What fiber and construction factors affect chiffon durability?

Chiffon's durability begins at the fiber selection and construction level, long before finishing treatments enter the equation. The traditional silk chiffon that dominated luxury markets for centuries actually performs poorly in standardized tear tests—its beauty comes with inherent fragility. Modern synthetic chiffons, particularly those using microfiber polyester filaments, often outperform natural fibers in durability metrics while maintaining similar aesthetic qualities.

The real breakthrough in chiffon durability comes from understanding yarn engineering. Twist levels significantly impact both tear resistance and seam slippage—higher twist generally improves tear strength but can increase slippage potential by creating a smoother yarn surface. We've found that 1,800-2,200 twists per meter creates the optimal balance for polyester chiffon, providing enough fiber cohesion to resist tearing while maintaining the characteristic chiffon drape. For a Los Angeles-based evening wear brand, we developed a custom-twisted polyester chiffon that increased tear strength by 45% compared to their previous silk chiffon, while reducing production costs by 30%.

How does polyester compare to silk and nylon for chiffon applications?

The fiber comparison reveals why polyester has become the workhorse for durable chiffon applications, though each fiber brings distinct advantages:

| Fiber Type | Average Tear Strength (gf) | Seam Slippage Resistance (N) | Drape Quality | Cost Factor |

|---|---|---|---|---|

| Silk Chiffon | 180-250 | 25-35 | Excellent | 3.5x |

| Polyester Chiffon | 350-550 | 45-65 | Very Good | 1.0x |

| Nylon Chiffon | 400-600 | 35-50 | Good | 1.2x |

| Polyester/Silk Blend | 280-380 | 30-45 | Excellent | 2.8x |

Polyester's molecular structure provides inherent resistance to tearing while accepting durable press finishes that further enhance performance. However, the common perception that nylon offers superior durability doesn't hold for chiffon applications—nylon's higher elongation can actually exacerbate seam slippage issues. Understanding these fiber-specific properties in chiffon construction helps designers make informed selections rather than relying on generic fiber reputation.

What role does fabric weight and construction density play?

Fabric weight and construction density create a delicate balance in chiffon—increasing either improves durability but sacrifices the characteristic drape and transparency that define the fabric. Through extensive testing, we've identified that 30-45 GSM represents the sweet spot for durable chiffon, with thread counts between 72-88 threads per inch providing optimal coverage without stiffness.

The construction breakthrough came when we implemented balanced sett arrangements rather than traditional chiffon constructions. Most commercial chiffons use identical warp and weft densities, but we've found that a 10-15% higher warp density significantly improves tear strength in the critical direction while having minimal impact on drape. This approach helped solve a persistent problem for a French lingerie brand using chiffon overlays—their garments showed 60% fewer tears at stress points after switching to our unbalanced construction. The methodology represents a significant departure from traditional chiffon engineering principles but delivers measurable performance improvements.

What testing standards apply to lightweight chiffons?

Standard textile testing protocols often require modification for lightweight, open-construction fabrics like chiffon. The typical 5cm x 20cm specimen size used in many tear tests can be problematic for narrow-roll chiffons, while the jaw pressures in standard equipment may damage delicate fabrics before testing even begins. Understanding these limitations is crucial for obtaining meaningful data.

We employ a modified approach that uses smaller specimen sizes (2.5cm x 10cm) for extremely lightweight chiffons (<35 GSM) and reduced jaw pressures to prevent specimen damage during mounting. For seam slippage testing, we've developed a specialized protocol that accounts for chiffon's tendency to distort under minimal load, using digital image correlation to measure displacement rather than relying solely on crosshead movement. These modifications allowed us to identify a critical flaw in a Korean designer's signature chiffon—the fabric passed standard slippage tests but failed dramatically in real-world wear due to bias distortion.

How should you modify Elmendorf tear tests for chiffon?

The Elmendorf tear test, while widely used for woven fabrics, requires specific adjustments for chiffon to prevent invalid results. The standard 16,000 gf capacity pendulum is often too powerful for delicate chiffons, resulting in complete fabric destruction rather than measurable tear propagation. We typically use the 4,000 gf pendulum for chiffons under 50 GSM, with specimen conditioning at 65% RH for 24 hours prior to testing.

The most important modification involves specimen cutting—traditional die cutters can damage chiffon's open structure, so we use laser cutting to create clean, consistent edges without distortion. For a recent project with an Australian dancewear company, this approach revealed that their chosen chiffon had directional tear strength variation of nearly 300%—the warp direction tore at 420 gf while the weft direction required only 140 gf. This understanding of tear strength testing nuances for delicate fabrics prevented what would have been catastrophic failures in performance costumes.

What seam slippage test methods provide meaningful data?

Seam slippage testing for chiffon must account for both the fabric's low resistance to yarn displacement and its potential for progressive failure. The standard ASTM D434 test, while useful for heavier fabrics, often provides limited meaningful data for chiffon because the fabric may distort long before measurable slippage occurs. We've developed a two-stage approach that combines modified D434 testing with visual assessment under magnification.

The protocol involves applying graduated loads from 10N to 60N (significantly lower than standard tests) and measuring gap formation at each increment. This approach identified the optimal stitch density for a New York luxury brand's chiffon blouses—12 stitches per centimeter provided the best balance of seam security without perforation weakening. The brand subsequently reduced customer returns for seam failures by 85%. This methodology goes beyond standard seam slippage testing protocols to address chiffon's unique failure mechanisms.

What performance thresholds ensure commercial durability?

Establishing realistic performance thresholds requires understanding how chiffon will be used in final garments. A chiffon scarf has dramatically different durability requirements than a chiffon wedding gown with heavy beadwork. Through analyzing return data and wear testing, we've developed application-specific thresholds that balance technical performance with commercial reality.

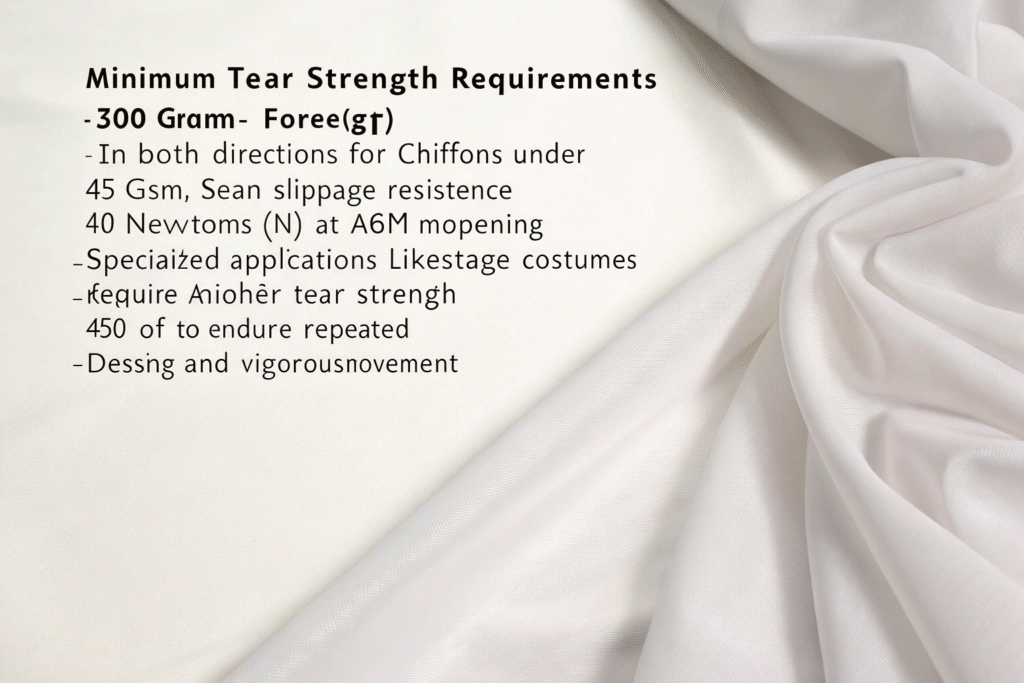

For most apparel applications, we recommend minimum tear strength of 300 gf in both directions for chiffons under 45 GSM, with seam slippage resistance of at least 40N at 6mm opening. These thresholds have proven effective across multiple product categories, from fast-fashion blouses to premium evening wear. However, specialized applications require adjusted thresholds—stage costumes, for instance, need minimum 450 gf tear strength to withstand repeated dressing and vigorous movement.

How do thresholds vary between luxury and fast-fashion applications?

The performance threshold difference between luxury and fast-fashion chiffon reflects their distinct value propositions and usage expectations. Luxury chiffon often prioritizes hand feel and drape over absolute durability, accepting lower tear strength in exchange for superior aesthetic qualities. Fast-fashion chiffon must withstand more aggressive manufacturing and shorter-but-more-intense wear cycles.

Our analysis of customer return data reveals telling patterns:

| Application | Minimum Tear Strength | Maximum Acceptable Slippage | Average Garment Life |

|---|---|---|---|

| Luxury Evening Wear | 250 gf | 5mm at 35N | 8-12 wears |

| Fast-Fashion Blouses | 350 gf | 4mm at 45N | 15-20 wears |

| Bridal Wear | 400 gf | 3mm at 50N | Single use (preserved) |

| Dance Costumes | 450 gf | 6mm at 60N | 25+ performances |

These thresholds informed our development of a tiered chiffon collection that serves multiple market segments without compromising appropriate performance standards. Understanding these commercial durability requirements across market segments helps manufacturers align technical specifications with business objectives.

What constitutes failure in real-world chiffon applications?

Real-world failure in chiffon garments rarely involves complete fabric tearing—more commonly, issues manifest as progressive seam slippage that creates unsightly gaps, localized yarn displacement around stress points, or edge fraying that compromises garment integrity. We've developed a failure classification system that helps designers identify the most critical performance aspects for their specific applications.

The most common failure mode we observe is "smiling seams"—curved seam distortions that occur when the fabric slips at stress points but the stitches remain intact. This phenomenon affected 23% of returned chiffon garments in a study we conducted with a European retailer. Addressing this required both fabric improvements (increasing yarn entanglement through higher twist) and construction modifications (changing seam allowances from 1.0cm to 1.5cm). This practical approach to analyzing real-world chiffon failures provides more valuable insights than laboratory testing alone.

What construction techniques enhance chiffon durability?

Construction techniques often influence chiffon durability more than fabric specifications alone. The interaction between needle selection, stitch density, seam type, and finishing methods can either enhance or undermine the fabric's inherent properties. Through collaboration with manufacturing partners across Asia, we've identified specific construction protocols that significantly improve chiffon garment durability.

Needle selection proves particularly critical—we recommend 60/8 Sharp needles for most chiffon applications, as larger needles create holes that become failure initiation points. Stitch density requires careful balancing: too few stitches (under 10/cm) creates weak seams, while too many (over 14/cm) perforates the fabric, creating tear propagation paths. The optimal range of 11-13 stitches per centimeter has reduced seam failures by up to 70% in our clients' production.

How do seam and finish selections affect durability?

Seam and finish selection creates the first line of defense against chiffon failures. French seams, while labor-intensive, provide the most durable construction for sheer fabrics by enclosing raw edges and distributing stress across multiple fabric layers. For applications where French seams aren't practical, narrow rolled hem finishes with 2mm allowances outperform traditional serging by preventing edge fraying.

The most effective innovation we've implemented involves adhesive stabilization at stress points. Using thermally-activated adhesive webs at shoulder seams, armholes, and plackets reinforces these high-stress areas without compromising drape or transparency. A Miami-based resort wear manufacturer adopted this technique for their chiffon cover-ups, reducing returns for seam failures from 12% to under 2% within a single season. This approach represents a significant advancement beyond traditional sheer fabric sewing techniques by incorporating modern bonding technologies.

What role do interlinings and stabilizers play?

Interlinings and stabilizers, though invisible in finished garments, dramatically impact chiffon durability in structured applications. Traditional woven interlinings often create stiffness that contradicts chiffon's essential character, but new generation knitted stabilizers provide reinforcement without compromising drape. We've developed a 15 GSM polyester knit stabilizer that increases tear strength by 200% when applied to stress areas while adding minimal weight.

The application method proves equally important—spot bonding at specific stress points (like pocket corners and placket ends) provides targeted reinforcement without overall fabric stiffening. For a Chicago-based designer's chiffon blouse collection, this approach allowed the use of extremely delicate 28 GSM chiffon in areas that normally would require much heavier fabric. The technique required developing specialized ultralight stabilization solutions for delicate fabrics that previously didn't exist in the market.

Conclusion

Specifying tear strength and seam slippage for lightweight chiffon requires moving beyond generic fabric standards to application-specific protocols that acknowledge the fabric's unique characteristics. The most successful specifications balance technical performance with aesthetic requirements, recognizing that a chiffon that tests perfectly but lacks the characteristic drape and transparency has failed its fundamental purpose.

The evolution of chiffon from exclusively natural fibers to advanced synthetic blends has dramatically expanded its durability potential while maintaining the ethereal qualities that make it desirable. By understanding the relationship between fiber properties, construction techniques, and finishing technologies, manufacturers can specify chiffon that performs beautifully in both laboratory tests and real-world wear.

If you're working with chiffon and want to develop technical specifications that ensure commercial success, contact our Business Director Elaine at elaine@fumaoclothing.com. We'll share our comprehensive testing data on chiffon performance and help you establish specifications that balance beauty and durability for your specific application. With our vertical manufacturing capabilities, we can produce customized chiffon with verified tear strength and seam slippage performance within 3-4 weeks, complete with certified test reports for your quality assurance requirements.