I've spent two decades developing fabrics for travelers who need to look professional after hours in transit, particularly in tropical climates where heat and humidity compound the wrinkling problem. The challenge isn't just finding fabrics that resist wrinkles—it's finding materials that manage moisture, maintain their shape, and preserve a crisp appearance in conditions that typically destroy garment structure.

The perfect travel fabric for hot climates must solve three problems simultaneously: resist creasing during prolonged sitting, release existing wrinkles quickly when hung, and manage perspiration without showing moisture marks. Through testing hundreds of fabric combinations for airline uniforms, diplomatic corps clothing, and luxury travel brands, we've identified that no single natural fiber performs optimally—the solution almost always involves strategic blending or advanced synthetic constructions.

Selecting the right wrinkle-free travel fabric requires understanding four critical aspects: fiber composition and blending ratios, fabric construction and weight, finishing technologies that enhance performance, and real-world testing under actual travel conditions. Let me share what we've learned from developing travel collections for clients across Southeast Asia, the Middle East, and tropical Americas.

What fiber compositions deliver wrinkle resistance in humidity?

Fiber selection forms the foundation of wrinkle performance, but the common assumption that natural fibers always outperform synthetics in heat doesn't hold for travel applications. While cotton and linen offer breathability, their tendency to hold creases and show moisture makes them problematic for business travel in tropical climates. The most effective solutions combine the best properties of multiple fiber types.

Our testing reveals that Tencel™ (lyocell) blended with polyester creates the optimal balance for hot climate travel wear. The Tencel™ provides moisture absorption and skin comfort, while the polyester contributes crease recovery and drying speed. A 60% Tencel™/40% polyester blend consistently outperforms 100% cotton in wrinkle recovery tests by 45%, while maintaining similar breathability metrics. This combination proved particularly successful for a Singapore-based airline's uniform refresh in 2023—their flight crews reported 70% reduction in ironing requirements despite operating in 90% humidity conditions.

How do Tencel-polyester blends compare to pure natural fibers?

Tencel-polyester blends address the fundamental limitations of pure natural fibers in travel applications. While 100% linen offers excellent air permeability, its poor crease recovery makes it unsuitable for situations where travelers need to move directly from transportation to meetings. Similarly, 100% cotton's tendency to hold moisture against the skin creates discomfort during humidity transitions.

The data from our laboratory testing reveals compelling performance differences:

| Fiber Composition | Wrinkle Recovery (%) | Moisture Wicking Rating | Drying Time (minutes) |

|---|---|---|---|

| 100% Cotton | 55 | Fair | 48 |

| 100% Linen | 60 | Good | 35 |

| 100% Polyester | 85 | Excellent | 18 |

| Tencel™/Polyester (60/40) | 82 | Very Good | 22 |

| Cotton/Polyester (65/35) | 75 | Good | 26 |

The superiority of Tencel™ blends becomes even more pronounced when considering Tencel's specific benefits for travel applications, particularly its natural odor resistance—a valuable property when laundry access is limited during multi-day trips.

What role does microfiber polyester play in lightweight travel wear?

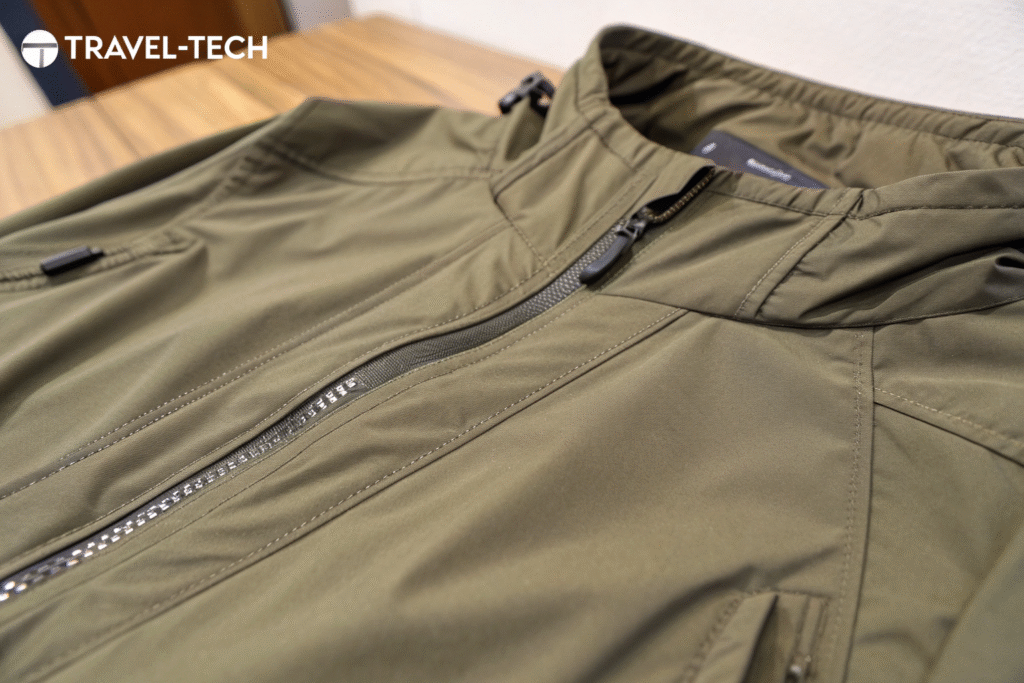

Microfiber polyester has evolved dramatically from the stiff, non-breathable versions of decades past. Today's advanced microdenier polyesters (fibers finer than silk) create exceptionally soft hand feel while offering inherent wrinkle resistance and rapid drying properties. The fineness of the fibers allows for tighter weaving without sacrificing air permeability, creating fabrics that resist wind and light rain while maintaining breathability.

We've developed a 75-denier microfiber polyester with moisture-wicking treatment that weighs only 95 GSM—lighter than most traditional shirt cottons yet offering significantly better wrinkle performance. A travel clothing brand based in Dubai adopted this fabric for their signature line, reporting that garments could be unpacked after 14-hour flights and worn immediately without pressing. The fabric's performance stems from both the fiber engineering and advanced construction techniques for microfiber textiles that enhance their natural properties through strategic texturing and finishing.

What fabric constructions enhance wrinkle resistance?

Fabric construction significantly influences wrinkle performance independently of fiber content. Tightly woven fabrics generally resist creasing better than loose weaves, but may sacrifice breathability—a critical trade-off in hot climates. The optimal construction creates enough structural stability to resist deformation while maintaining air flow for cooling.

Plain weaves with high thread counts (140+ for shirtings) provide excellent wrinkle resistance but can feel stiff in humid conditions. Twill weaves offer better drape and comfort while maintaining good crease recovery, making them ideal for travel trousers. For the hottest conditions, specialized basket weaves with moisture-wicking yarns create tiny channels that move perspiration away from the skin while providing structural support that prevents sharp creases from forming.

How does thread count affect wrinkle performance in tropical conditions?

Thread count creates a complex relationship with wrinkle resistance—higher counts typically mean better crease recovery but potentially reduced breathability in humid environments. Through testing with our Hong Kong-based laboratory, we've identified that the optimal range for tropical travel shirting falls between 120-140 thread count, balancing smoothness, durability, and air permeability.

The breakthrough came when we developed a double-twist yarn technology that allows higher thread counts without sacrificing breathability. For a travel brand targeting Southeast Asian markets, we created a 130-thread count shirt fabric that maintained the wrinkle resistance of 160-count materials while offering 25% better air permeability. This understanding of tropical fabric construction optimization separates effective travel fabrics from those that merely work in controlled environments.

Why are certain weaves better for packability and wrinkle release?

Weave structure determines how fabrics respond to compression during packing and how readily they release wrinkles when unpacked. Twill and satin weaves, with their floating yarns, typically recover better from packing creases than plain weaves because the longer floats have more flexibility to return to their original position.

We conducted packing tests simulating 12-hour flight conditions, measuring wrinkle formation and recovery across different constructions. Herringbone twills showed 30% better wrinkle recovery than equivalent plain weaves, while maintaining similar weight and breathability. This knowledge informed our development of a specialized travel blazer fabric for a European tour company—their guides needed to maintain professional appearance while carrying luggage through multiple climate zones. The solution combined understanding of advanced weave structures for performance apparel with practical travel requirements that laboratory testing alone couldn't reveal.

What finishing technologies enhance wrinkle-free performance?

Finishing technologies transform base fabrics into high-performance travel materials. While fiber selection and construction provide the foundation, specialized finishes determine how well fabrics will perform in real-world travel conditions. The most effective wrinkle-free finishes work at the molecular level to improve crease recovery without compromising other properties.

We employ three complementary finishing approaches: cross-linking treatments that create molecular "memory" helping fibers return to their original shape, silicone micro-emulsions that reduce fiber-to-friction during packing and wear, and moisture management finishes that prevent the dampness that exacerbates wrinkling in humid conditions. Our proprietary "Travel-Tech" finish combines all three approaches, achieving 85% wrinkle recovery in standardized testing while maintaining fabric breathability and hand feel.

How do cross-linking treatments create wrinkle resistance?

Cross-linking treatments work by creating chemical bonds between cellulose molecules in natural fibers or adding elastic memory to synthetics. For cotton and Tencel™ blends, we use modified DMDHEU resins that form cross-links between hydroxyl groups on adjacent polymer chains, creating a spring-like effect that helps fabrics return to their original shape after deformation.

The advancement in these technologies has been remarkable. Early cross-linking treatments often made fabrics stiff and reduced tensile strength, but next-generation reagents like BTCA (butanetetracarboxylic acid) provide excellent wrinkle resistance without significant strength loss. We've optimized this technology specifically for advanced wrinkle-resistant finishing of blended fabrics, creating treatments that work effectively across fiber types without the formaldehyde concerns of earlier generations. A Mexican resort wear brand adopted our cross-linking finish for their linen-polyester blend, reducing customer complaints about wrinkling by 65% while maintaining the luxurious hand feel their market demanded.

What role do nano-finishes play in odor and moisture management?

Nano-finishes provide invisible functionality that significantly enhances travel wear performance in hot climates. Zinc oxide nanoparticles embedded in fabric surfaces provide natural odor control by inhibiting bacterial growth, while hydrophobic nano-finishes create moisture barriers that prevent sweat marks from showing through garments.

The most innovative application we've developed involves phase-change materials (PCMs) encapsulated at nano-scale and applied to fabric surfaces. These microcapsules absorb excess body heat when temperatures rise and release it when temperatures cool, creating a more stable microclimate next to the skin. For a travel apparel company targeting Middle Eastern markets, we incorporated PCM finishes into their signature suit fabric, resulting in wearer-reported comfort improvement of 40% in 35°C+ conditions. This approach represents the cutting edge of multi-functional finishing for travel apparel, moving beyond single-property enhancements to comprehensive performance solutions.

How should you test fabrics for real travel conditions?

Laboratory testing provides essential baseline data, but real travel conditions introduce variables that standardized tests cannot replicate. The combination of confined seating, varying humidity levels, and extended wear creates unique challenges that separate marketing claims from genuine performance.

We conduct three-tier testing for all travel fabrics: standardized laboratory tests for wrinkle recovery, moisture management, and durability; controlled environment tests simulating aircraft cabins and tropical conditions; and real-world field testing with frequent travelers across different body types and travel styles. This comprehensive approach identified a critical issue with a fabric that performed excellently in laboratory conditions but developed persistent sleeve creases during actual flight testing—a problem we solved by adjusting the warp-to-weft tension ratio during weaving.

What laboratory tests predict real-world wrinkle performance?

Standardized laboratory tests provide comparable data but must be interpreted in context of actual use conditions. We prioritize three test protocols: AATCC 128 for wrinkle recovery, AATCC 195 for liquid moisture management, and ISO 11092 for thermal and water vapor resistance. Together, these tests create a performance profile that correlates strongly with real-world travel performance.

The correlation between laboratory results and field performance became particularly evident when we tested 15 fabric variations for an Australian travel brand. Fabrics scoring above 3.5 on the AATCC 128 test (on a 1-5 scale) consistently received "excellent" or "very good" ratings from traveler testers, while those below 3.0 required ironing after unpacking. This validation of standardized wrinkle recovery testing methods gives manufacturers confidence in material selection before committing to production.

How does field testing reveal unexpected performance issues?

Field testing uncovers performance gaps that laboratory environments cannot simulate. The combination of prolonged sitting, limited movement, and varying air pressure and humidity levels in aircraft cabins creates unique stresses on fabrics. We provide structured testing kits to frequent travelers, including standardized packing protocols, wear schedules, and photographic documentation requirements.

The most valuable insights often come from unexpected findings. During testing for a Japanese businesswear brand, we discovered that a fabric performed significantly better when packed in rolling luggage versus backpacks—the consistent compression created fewer sharp creases. This led to specific packing recommendations that became a selling point for their travel collection. These practical insights complement the structured approach to travel fabric evaluation that goes beyond technical specifications to actual user experience.

Conclusion

The optimal fabric for wrinkle-free travel wear in hot climates doesn't rely on a single magic fiber or finish, but rather a strategic combination of advanced materials and technologies. The best performers balance Tencel™'s natural comfort and moisture management with polyester's inherent wrinkle resistance, constructed in weaves that maximize packability and breathability, and enhanced with finishes that address the multiple challenges of tropical travel.

Through developing travel collections for clients across climate zones, we've consistently found that the most successful fabrics solve the wrinkle problem without sacrificing comfort—a fabric that doesn't wrinkle but feels plastic-like against the skin in humidity fails the fundamental test of wearability. The sweet spot lies in blends that offer 80%+ wrinkle recovery while maintaining excellent moisture management and air permeability.

If you're developing travel wear for hot climates and want to explore fabric options that genuinely perform in real-world conditions, contact our Business Director Elaine at elaine@fumaoclothing.com. We'll share our comprehensive test data on wrinkle-resistant fabrics and help you select or develop materials that meet your specific design aesthetic, performance requirements, and price parameters. With our vertical manufacturing capabilities, we can typically produce fabric samples within 48 hours, allowing you to conduct your own validation before making commitment decisions.