After twenty years of supplying fabric to global brands, I've seen tech packs that could win design awards and others that would confuse a rocket scientist. The difference in approval time between them can be weeks versus days. Just last month, a client's poorly structured tech pack caused three weeks of delays and $15,000 in missed production slots. The truth is, a well-designed Bill of Materials (BOM) and tech pack aren't just documentation—they're your manufacturing blueprint that either accelerates or sabotages your timeline.

A fabric BOM and tech pack speed approvals when they provide complete, unambiguous information in standardized formats that leave zero room for interpretation. The most effective packages include detailed material specifications, precise performance requirements, clear testing protocols, and visual references that eliminate guesswork. Brands that master this process typically reduce approval cycles by 60-80% and cut sampling iterations from 4-5 rounds to 1-2.

I remember working with a Danish brand that had the most beautiful tech packs imaginable—visually stunning but missing critical information. Their "navy blue" specification lacked Pantone numbers, their "soft handfeel" had no measurable parameters, and their weight tolerance was "as light as possible." We spent six weeks going back and forth instead of the ten days it should have taken. The experience taught me that beauty without precision is worthless in manufacturing.

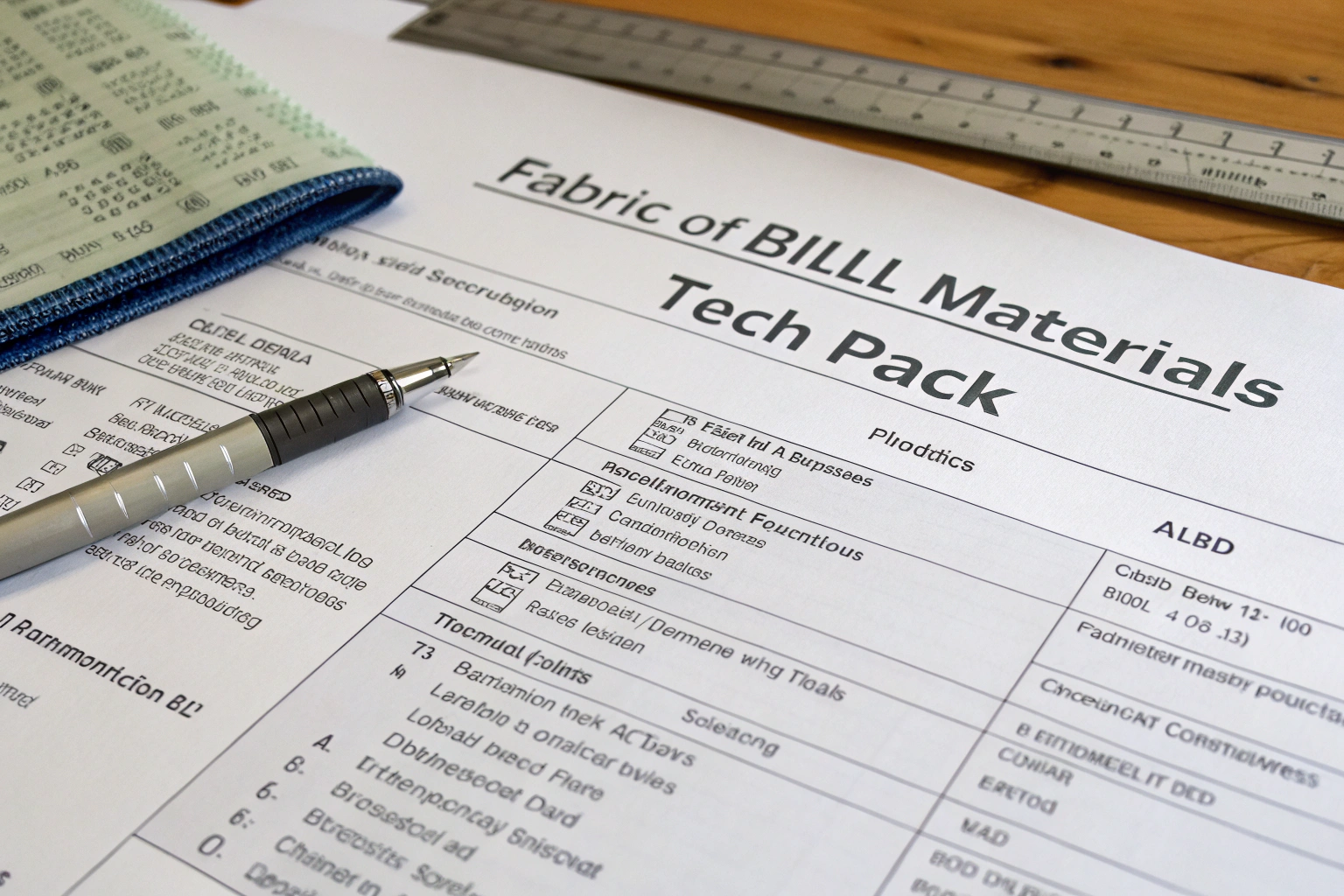

What Essential Elements Make a Fabric BOM Unambiguous?

The Bill of Materials is your ingredient list—it must be precise, comprehensive, and measurable. An ambiguous BOM guarantees delays, while a clear one sets the foundation for rapid approvals. The most effective BOMs follow a standardized structure that leaves no room for supplier interpretation.

A complete fabric BOM should read like a scientific formula rather than a creative brief. Every element must be quantifiable, testable, and reference industry standards. When we receive BOMs with vague terms like "premium quality" or "good durability," we know immediately that we're facing multiple sampling rounds and inevitable delays.

How Should You Specify Fiber Content and Construction?

Fiber content and construction details form the foundation of your fabric specification. Vague descriptions like "cotton blend" or "knitted fabric" guarantee misunderstandings. Instead, use precise technical language backed by measurable parameters.

Complete Fiber Specification:

- Exact percentages: "65% cotton, 35% polyester" not "cotton blend"

- Yarn details: "40/s combed cotton, 75D polyester filament"

- Certification requirements: "GOTS certified organic cotton, GRS recycled polyester"

- Finish specifications: "Silicone softener, DWR finish"

Construction Clarity:

- Weave/knit type: "2x2 twill weave" not "woven fabric"

- Thread count: "130x70 threads per inch"

- Weight with tolerance: "185 GSM ±5%" not "medium weight"

- Width specification: "57/58" finished width"

When a UK retailer started including yarn twist levels and spinning methods in their BOMs, their fabric approval time dropped from 21 days to 9 days. The precise specifications eliminated the "this doesn't feel right" feedback that previously caused multiple sampling rounds.

What Performance Standards Eliminate Subjective Testing?

Performance requirements must reference established test methods and acceptable results. Instead of "good colorfastness," specify "Colorfastness to washing: ISO 105-C06 A1S ≥4, Colorfastness to light: ISO 105-B02 ≥4."

We recommend this standardized performance table format:

| Test Parameter | Test Method | Requirement | Tolerance |

|---|---|---|---|

| Tensile Strength | ASTM D5034 | Warp: 300N, Weft: 250N | -10% |

| Tear Strength | ASTM D1424 | Warp: 15N, Weft: 12N | -15% |

| Martindale Abrasion | ASTM D4966 | 30,000 cycles | No holes |

| Dimensional Stability | AATCC 135 | ±3% shrinkage | None |

A German workwear brand implemented this approach and reduced their performance testing disputes by 90%. Their suppliers now know exactly what's required, and their quality team has clear pass/fail criteria.

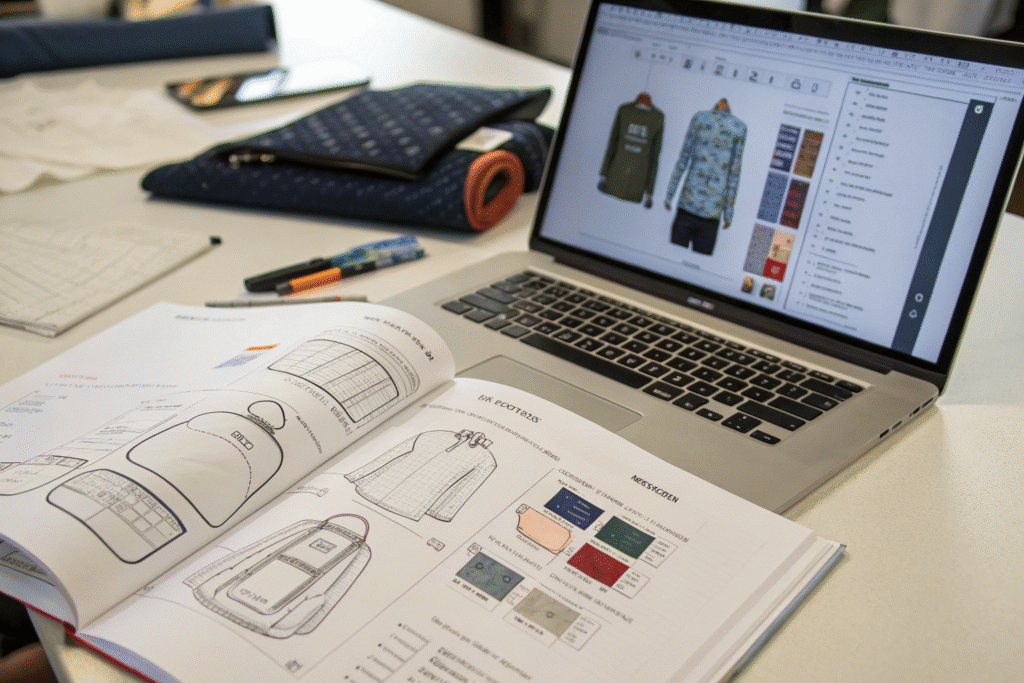

How Does Tech Pack Visualization Accelerate Understanding?

While the BOM provides the technical foundation, the tech pack creates the visual context that brings specifications to life. The most effective tech packs combine precise technical data with clear visual references that eliminate ambiguity about the desired outcome.

Humans process visual information 60,000 times faster than text, which means your tech pack's visual elements often communicate more effectively than pages of specifications. However, the visuals must be accurate, labeled, and referenced to the corresponding technical data.

What Visual References Prevent Misinterpretation?

Effective tech packs include multiple visual reference types, each serving a specific purpose:

Physical Reference Standards:

- Approved pantone swatches with spectrophotometer readings

- Fabric handfeel standards with measurable roughness parameters

- Weight and thickness samples for tactile comparison

- Surface finish references (brushed, peach, calendered)

Digital Visual Aids:

- Macro photography of desired fabric surface

- Cross-section diagrams of complex constructions

- Drape simulation for fluidity requirements

- Color application mockups for printed patterns

A Spanish fast-fashion brand reduced their fabric development time by 40% simply by adding high-resolution macro photos of the desired fabric surface to their tech packs. The images communicated texture expectations that words couldn't capture.

How Do You Structure Approval Workflows in Tech Packs?

Clear approval workflows prevent the "who needs to approve what" confusion that stalls projects. Your tech pack should explicitly state:

- Approval hierarchy: Who has final sign-off authority

- Review timeline: Maximum time for each approval stage

- Feedback format: Standardized comment templates

- Revision tracking: Clear version control system

We developed a digital approval portal for a US brand that reduced their average approval time from 14 days to 3 days. The system automatically routed submissions to the correct approvers, tracked response times, and maintained complete revision histories.

What Information Prevents Production Delays?

The most frustrating delays occur when fabric passes development approval but fails in production due to missing information. Your BOM and tech pack must bridge this gap by including production-specific details that mass manufacturers require.

Development samples often come from lab-scale equipment, while production uses industrial machinery with different capabilities. Your documentation must account for these differences to ensure smooth scaling from sample to bulk.

How Do You Specify Tolerances for Manufacturing Reality?

All manufacturing has natural variation, but unspecified tolerances guarantee disputes. Your BOM must include realistic, measurable tolerances for every parameter:

Critical Tolerance Specifications:

- Color tolerance: ∆E ≤ 1.0 under D65 illumination

- Weight tolerance: ±3% for wovens, ±5% for knits

- Width tolerance: ±1 cm for finished fabric

- Shade band range: 3-5 steps with ∆E 0.5 increments

When a French luxury brand started specifying their tolerances explicitly, their first-pass production approval rate improved from 65% to 88%. The clear parameters eliminated arguments about whether variations were acceptable.

What Logistical Information Ensures Smooth Production?

Production involves more than just fabric manufacturing. Your tech pack should include logistical requirements that affect production planning:

- Roll length requirements: Minimum and maximum roll lengths

- Packaging specifications: Polybag, cardboard core, labeling

- Inspection protocols: AQL levels, defect classification

- Shipping markings: Carton labeling, documentation requirements

A Canadian brand learned this lesson when their beautiful fabric arrived in 20-meter rolls instead of the 100-meter rolls their factory required. The resulting splicing and waste cost them $8,000 and delayed their production by two weeks.

How Can Digital Tools Streamline the Process?

While traditional PDF tech packs work, digital platforms dramatically accelerate the approval process through automation, collaboration features, and version control. The most effective systems integrate directly with supplier management platforms.

Digital transformation in tech pack management isn't about technology for technology's sake—it's about eliminating the communication gaps and version control issues that cause delays.

What Features Matter in Digital Tech Pack Systems?

Effective digital systems should provide:

- Centralized storage: Single source of truth for all specifications

- Automated formatting: Standardized templates that prevent missing information

- Real-time collaboration: Simultaneous multi-user editing with change tracking

- Integration capabilities: Links to PLM, ERP, and supplier systems

- Mobile accessibility: Review and approval from any device

A Swedish brand implemented a digital system and reduced their tech pack creation time from 5 days to 1 day while eliminating the version control issues that previously caused 30% of their development delays.

How Do You Manage Supplier Access and Security?

Digital systems require careful access management to protect intellectual property while enabling supplier collaboration. We recommend tiered access levels:

- Full access: Primary development partners

- View-only with download restrictions: Sampling suppliers

- Section-specific access: Component specialists

- Temporary access: New vendor evaluations

An American outdoor brand using this approach maintained their design security while reducing the time to onboard new fabric suppliers from 3 weeks to 3 days.

What Are the Cost Benefits of Proper Documentation?

Investing in comprehensive BOM and tech pack development delivers substantial financial returns through reduced sampling costs, faster time-to-market, and improved production efficiency. The documentation costs are minimal compared to the savings from prevented delays.

Poor documentation creates hidden costs throughout the supply chain—from unnecessary sampling iterations to production reworks and missed delivery windows. These costs typically exceed the investment in proper documentation by 10:1 or more.

How Much Does Proper Documentation Actually Cost?

The investment includes:

- Software tools: $200-500/month for professional systems

- Training time: 2-3 days for design and technical teams

- Template development: 1-2 weeks for standardized formats

- Process implementation: 1 month for workflow establishment

The total $5,000-10,000 first-year investment is recouped many times over through saved sampling costs alone.

What ROI Can You Expect from Improved Documentation?

Typical returns include:

- 50-70% reduction in sampling costs

- 60-80% faster approval cycles

- 40-60% improvement in first-time production quality

- 30-50% reduction in specification-related disputes

An Australian fashion brand tracked their metrics and found that improving their tech packs saved them $28,000 in sampling costs and 42 production days in their first season—delivering 450% ROI on their documentation investment.

Conclusion

A well-designed fabric BOM and tech pack serve as your manufacturing compass, guiding every stakeholder toward the same destination with minimal detours. The most effective documentation combines precise technical specifications with clear visual references, establishes realistic tolerances, and implements streamlined approval workflows. While creating comprehensive documentation requires initial investment, the returns through faster approvals, reduced sampling, and improved production quality are substantial and rapid.

At Fumao Textiles, we've developed standardized BOM and tech pack templates that have helped our clients reduce fabric development time by up to 70%. Our experience across thousands of fabric developments has taught us what information accelerates rather than obstructs the approval process. We don't just follow your specifications—we help you create specifications that manufacturing partners can execute flawlessly. If you're tired of approval delays and sampling iterations, contact our Business Director Elaine at elaine@fumaoclothing.com. Let's build documentation that speeds your fabric from concept to production.

21 Responses

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://www.binance.info/register?ref=IHJUI7TF

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://www.binance.com/register?ref=IHJUI7TF

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://accounts.binance.com/vi/register-person?ref=MFN0EVO1

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://www.binance.com/ES_la/register?ref=VDVEQ78S

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your article helped me a lot, is there any more related content? Thanks! https://www.binance.com/register?ref=IXBIAFVY

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://accounts.binance.info/si-LK/register-person?ref=LBF8F65G

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your article helped me a lot, is there any more related content? Thanks! https://accounts.binance.info/pl/register-person?ref=UM6SMJM3

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://www.binance.info/en/register?ref=JHQQKNKN

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Touche. Outstanding arguments. Keep up the amazing effort.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://www.binance.com/zh-CN/register?ref=WFZUU6SI