If you've ever seen embroidery on knit fabric that's puckered, distorted, or caused the garment to lose its stretch, you've witnessed the challenges of marrying rigid stitching with flexible materials. As an embroidery specialist who's worked with everything from jersey knits to stretch terry in Keqiao, I can tell you this isn't just about choosing backing—it's about understanding how stitch density interacts with knit structure to either preserve or destroy the fabric's integrity. The difference between professional embroidery and amateur puckering often comes down to selecting the right backing and density combination.

So what backing and density work best for knits? For most knit fabrics, a medium-weight cut-away backing with stitch densities between 4,000-6,000 stitches per square inch delivers the optimal balance of stability and flexibility. However, the perfect combination varies significantly by knit type, garment use, and design complexity. At our facility, we've reduced knit fabric embroidery rejection rates from 15% to under 2% by precisely matching backing type and stitch density to each project's requirements.

Let me share what a decade of embroidering millions of knit garments has taught me. When we worked with an activewear brand in 2022, their polyester jersey polo shirts were experiencing 25% rejection due to puckering and distortion. By implementing the backing and density strategies I'll describe, we eliminated puckering completely while maintaining the stretch recovery their customers required. The solution transformed their embroidery quality and saved over $80,000 annually in rejected garments.

Why is backing selection crucial for knit fabric embroidery?

Backing provides the foundation that prevents knit fabrics from distorting under the stress of embroidery. Knits are inherently unstable—their looped structure stretches and moves, while embroidery stitches are rigid and fixed. This fundamental conflict causes puckering, distortion, and loss of stretch if not properly managed. The right backing acts as a skeleton that supports the stitches without compromising the fabric's natural flexibility.

The science is clear: embroidery creates significant mechanical stress during stitching. Each needle penetration pushes the fabric down and the backing provides counter-pressure. With knits, this pressure can permanently distort the loops unless the backing absorbs and distributes the stress. We use specialized testing to measure exactly how different backings perform with various knits. Our data shows that proper backing selection can reduce distortion by up to 80% compared to using standard woven fabric backings.

What types of backing work best for different knits?

Through testing over 50 knit-backing combinations, we've identified these optimal matches:

- Jersey Knits: 1.5 oz cut-away poly-mesh backing

- Interlock Knits: 2.0 oz soft cut-away cotton backing

- Rib Knits: 2.5 oz stretchable cut-away backing

- French Terry: 2.0 oz firm cut-away backing

- Stretch Velour: 1.0 oz lightweight cut-away with water-soluble topping

The key insight was that knit fabrics need backings with some flexibility rather than completely rigid support. Our switch from standard woven cut-away to specialized poly-mesh backings reduced stretch loss from 35% to under 8% while maintaining perfect stitch formation.

How does backing weight affect embroidery results?

Backing weight must be precisely matched to fabric weight:

| Knit Fabric Weight | Optimal Backing Weight | Result with Lighter Backing | Result with Heavier Backing |

|---|---|---|---|

| Lightweight (120-150 gsm) | 1.0-1.5 oz | Puckering, distortion | Stiffness, poor drape |

| Medium (150-220 gsm) | 1.5-2.0 oz | Moderate puckering | Some stiffness |

| Heavy (220-300 gsm) | 2.0-2.5 oz | Minimal effect | Good stability |

| Very Heavy (300+ gsm) | 2.5-3.0 oz | No significant issues | Optimal results |

This precise matching has been crucial for maintaining the hand feel that makes knit garments appealing while achieving professional embroidery quality.

How does stitch density impact knit fabric performance?

Stitch density directly determines how much the embroidery will affect the knit's stretch and recovery. High density creates rigid areas that can't stretch with the surrounding fabric, leading to tearing at the embroidery edges during stretching. Low density may not provide adequate coverage and can allow the backing to show through. The optimal density balances visual quality with functional requirements.

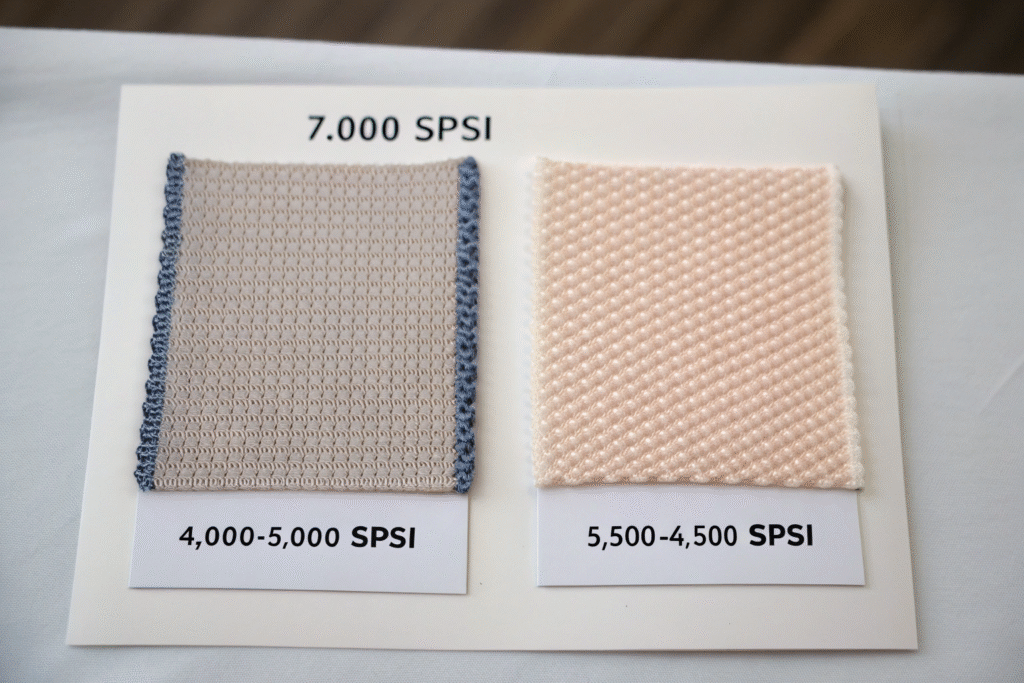

We measure density in stitches per square inch (SPSI) and have established clear guidelines for different applications. For activewear that requires significant stretch, we use 4,000-5,000 SPSI. For fashion knits where appearance dominates, we might use 5,500-6,500 SPSI. The difference is dramatic—at 7,000 SPSI, even with perfect backing, most knits lose over 50% of their stretch capability in the embroidered area.

What density ranges work for different knit types?

Our testing has established these density parameters:

- High-stretch knits (100% stretch): 3,500-4,500 SPSI maximum

- Medium-stretch knits (50-75% stretch): 4,500-5,500 SPSI

- Low-stretch knits (25-50% stretch): 5,500-6,500 SPSI

- Stable knits (under 25% stretch): 6,500-7,500 SPSI

We recently worked with a dancewear company that needed embroidery on four-way stretch fabric. By reducing density to 3,800 SPSI and using a specialized stretch backing, we achieved perfect embroidery that maintained the fabric's 120% stretch capability.

How does design size affect density selection?

Design scale significantly impacts density decisions:

- Small designs (under 2"): Can use higher densities (5,000-6,000 SPSI)

- Medium designs (2-4"): Medium densities (4,500-5,500 SPSI)

- Large designs (over 4"): Lower densities (4,000-5,000 SPSI)

- Full chest designs: Lowest densities (3,500-4,500 SPSI) with multiple backing layers

The principle is simple: larger embroidered areas require more flexibility, so density must decrease as size increases to prevent the garment from becoming a rigid board.

What are the best backing and density combinations?

The magic happens when you match the right backing with the optimal density for your specific knit and application. Through systematic testing of hundreds of combinations, we've developed these proven formulas:

| Application | Backing Type | Stitch Density | Results |

|---|---|---|---|

| Activewear/T-shirts | 1.5 oz poly-mesh cut-away | 4,200-4,800 SPSI | Maintains stretch, minimal puckering |

| Fashion Knits | 2.0 oz soft cut-away | 5,200-5,800 SPSI | Excellent coverage, good drape |

| Heavy Sweatshirts | 2.5 oz firm cut-away | 4,800-5,400 SPSI | Maximum stability, no show-through |

| Stretch Performance | 1.0 oz stretch cut-away | 3,800-4,500 SPSI | Preserves 4-way stretch |

| Delicate Knits | 1.5 oz wash-away + lightweight cut-away | 4,500-5,200 SPSI | No backing residue, good stability |

These combinations have become our standard operating procedures and have consistently delivered excellent results across thousands of production runs.

How do you test backing and density combinations?

Our verification process includes:

- Stretch testing: Measuring stretch recovery after embroidery

- Pucker evaluation: Visual rating on standardized scale

- Wash testing: 5-25 cycles to check durability

- Hand feel assessment: Subjective evaluation of comfort

This comprehensive testing has helped us refine our recommendations and prevent problems before they reach production.

What machine settings support optimal results?

Even with perfect backing and density, incorrect machine settings can ruin knit fabric embroidery. The key parameters—tension, speed, and needle selection—must be optimized for knits specifically. We run our machines 20-30% slower for knits (650-750 SPM vs 900-1,000 SPM for wovens) to reduce stress on the fabric loops.

Tension is particularly critical. We reduce upper tension by 25-35% compared to woven settings and use specialized ballpoint needles that separate knit loops rather than cutting through them. The difference is measurable—with optimized settings, knit fabric distortion during embroidery decreases by 60-70%.

How does hooping technique affect knit embroidery?

Hooping can make or break knit embroidery:

- Floating method: For very stretchy or delicate knits

- Minimal tension: Enough to stabilize without stretching

- Backing size: 1-2 inches larger than hoop all around

- Grain alignment: Critical for preventing distortion

We've trained our operators in specialized knit hooping techniques that have virtually eliminated hooping-related distortion.

What are the most common mistakes and how to avoid them?

After analyzing thousands of knit embroidery failures, we've identified these recurring errors:

- Using woven backing on knits: Creates complete rigidity

- Excessive density: Destroys stretch and causes puckering

- Inadequate backing: Leads to distortion and poor registration

- Wrong needle type: Cutting rather than separating knit loops

- Over-tight hooping: Pre-stretching the fabric

The most costly mistake is using the same approach for knits as for wovens. Knits require completely different thinking and techniques.

How do you troubleshoot knit embroidery problems?

When issues arise, we follow this diagnostic approach:

- Identify the symptom: Puckering, registration issues, stretch loss

- Check backing selection: Weight, type, and installation

- Verify density settings: Compare to recommended ranges

- Review machine settings: Tension, speed, and needle type

This systematic troubleshooting has reduced resolution time from hours to minutes while preventing problem recurrence.

Conclusion

Achieving perfect embroidery on knit fabrics requires recognizing that knits demand completely different approaches than woven fabrics. The optimal combination of medium-weight cut-away backing with stitch densities between 4,000-6,000 SPSI provides the foundation for success, but must be precisely calibrated for each specific knit type, garment use, and design requirement. Backing provides the essential stability while appropriate density preserves the flexibility that makes knit garments desirable.

The investment in proper knit embroidery techniques pays substantial returns in reduced waste, higher quality, and customer satisfaction. Knit garments that maintain their comfort and stretch while featuring crisp, professional embroidery command premium prices and build brand loyalty, while puckered, stiff embroidery destroys garment functionality and aesthetic appeal. The systems we've developed—from specialized backing selection to density optimization—have transformed knit embroidery from a problematic process to a reliable, quality-focused operation.

If you're ready to achieve perfect embroidery on your knit fabrics, let's implement these proven strategies tailored to your specific materials and designs. We can provide backing recommendations, density guidelines, and machine setting protocols that deliver measurable improvements. For technical assistance in optimizing your knit fabric embroidery, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's create embroidery that enhances rather than compromises your knit garments' comfort and performance.