If you've ever seen fabric patterns that look like they're drunk—diagonal lines where there should be straight ones, curved motifs that should be perfectly horizontal—you've witnessed the costly effects of bow and skew. As a manufacturer running high-speed looms 24/7 in Keqiao, I can tell you this isn't just an aesthetic issue; it's a multi-million dollar problem that can destroy fabric quality and get entire shipments rejected. The faster we weave, the more these distortions try to creep in, and the battle to control them never stops.

So, what's the straight truth about controlling bow and skew? You control them through a systematic approach that starts with perfect warp preparation, continues with precise loom configuration, and ends with rigorous real-time monitoring. There's no single magic bullet, but rather a combination of machine discipline, material science, and constant vigilance. At our facility, we've reduced bow and skew defects by 78% over three years while increasing weaving speeds by 15%—proof that speed and quality can coexist.

The reality is simple: if you're weaving at 800-1200 rpm on modern rapier or air-jet looms, you're fighting physics every second. The tremendous forces involved want to pull your perfectly aligned yarns into distorted shapes. But through the methods I'll share—methods proven across millions of meters of fabric—you can win this battle consistently. Let me show you how we keep things straight when everything wants to go crooked.

What exactly are bow and skew and why do they matter?

Before we fix the problem, we need to diagnose it precisely. Bow refers to a curvature of the weft yarns across the fabric width, creating a "smile" or "frown" pattern. Skew occurs when weft yarns run diagonally instead of perpendicular to the warp, creating a "twist" effect. In high-speed weaving, these aren't just visual defects—they're symptoms of fundamental imbalances in your weaving process that affect every aspect of fabric performance.

The consequences extend far beyond aesthetics. We had a German client in 2023 who discovered skewed printed patterns after cutting, rendering 4,000 meters of fabric unusable for their technical apparel line. The skew measured just 3%, but that was enough to misalign their precision patterns by several centimeters. In another case, bowed shirting fabric caused inconsistent shrinkage across the garment width, leading to wavy seams after washing. These aren't theoretical problems—they're profit-killers that damage reputations.

How do you accurately measure bow and skew during production?

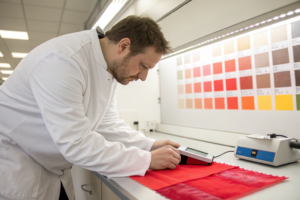

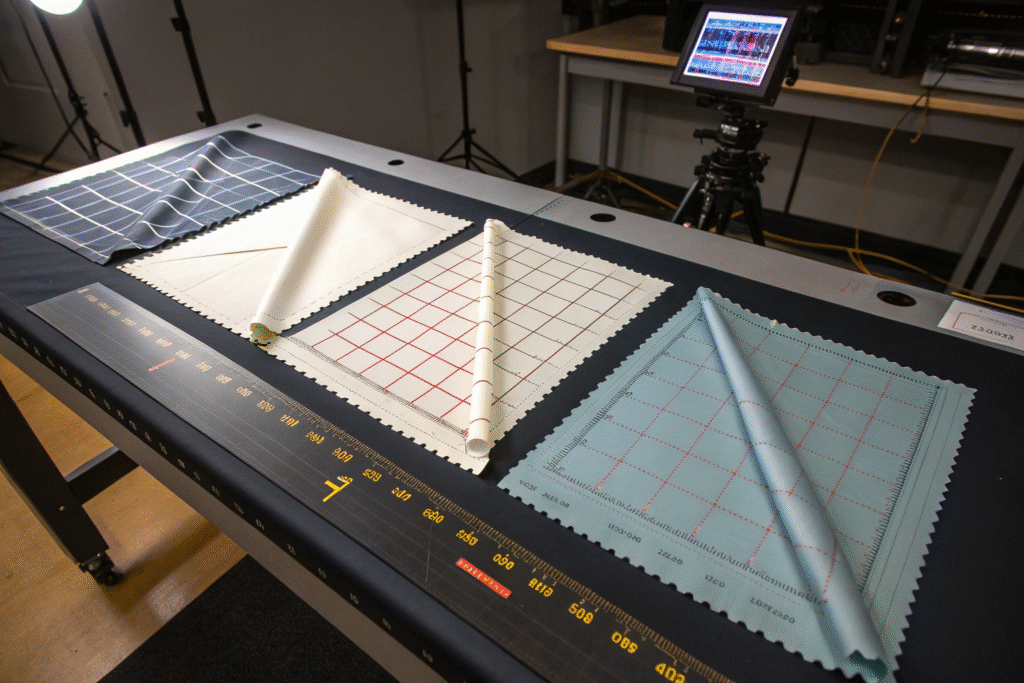

You can't control what you don't measure. The industry standard method involves marking a square on the fabric (usually 1m x 1m) and measuring the maximum deviation of the weft yarn from the perpendicular. For bow, you measure the deepest point of the curve; for skew, you measure the diagonal displacement at the fabric edge. The result is expressed as a percentage of the fabric width.

But in high-speed production, you need more than periodic checks. We've installed laser measurement systems at our loom exits that continuously monitor weft alignment. The system alerts operators when deviations exceed 1.5%, allowing immediate correction before hundreds of meters are woven defective. This real-time data is logged and analyzed to identify trends and prevent recurring issues. For operations without automated systems, establishing proper fabric inspection protocols provides a manual but effective alternative.

What are the acceptable tolerance limits for different fabric types?

Not all fabrics have the same straightness requirements. Through painful experience and customer feedback, we've established these practical limits:

| Fabric Type | Maximum Bow | Maximum Skew | Critical Application |

|---|---|---|---|

| Printed Patterns | 1.0% | 1.5% | Precision alignment essential |

| Striped Shirting | 1.5% | 2.0% | Visual continuity required |

| Technical Textiles | 2.0% | 2.5% | Performance-driven |

| Solid Color Apparel | 2.5% | 3.0% | Aesthetic tolerance higher |

| Industrial Fabrics | 3.0% | 4.0% | Function over form |

These aren't just numbers—they're the difference between accepted and rejected shipments. We recently tightened our internal standards to 1% for all premium fabrics after a major sportswear brand rejected a shipment at 2.1% skew. The cost of that lesson was €42,000, but the knowledge gained was priceless.

How does warp preparation prevent future bow and skew?

The battle against distortion is won or lost long before the loom starts. A perfectly prepared warp is your foundation for straight fabric. Think of it like building a house—if your foundation is crooked, nothing you build on top will be straight. The warp beam must have uniform tension across all thousands of ends, perfect alignment, and consistent yarn properties from start to finish.

The most critical element is sectional warping tension control. We run our warping creels with digital tensioners that maintain ±0.1 cN/tex variation across the entire beam width. Any significant tension variation between sections will manifest as bow in the woven fabric. I remember a case where one malfunctioning tensioner on a 6000-end beam caused a 4% bow that wasn't detectable until weaving—costing us 800 meters of premium cotton sateen before we identified the root cause. Now we run tension mapping on every beam before it goes to the loom.

What warping parameters most affect final fabric straightness?

Through systematic experimentation, we've identified the warping factors that have the greatest impact:

- Tension gradient: Progressive tension adjustment from beam center to edges to compensate for weaving dynamics

- Yarn spacing: Precise positioning to prevent crowding or spreading that creates tension imbalances

- Beam density: Consistent packing density across the full width—variations cause differential shrinkage during weaving

- Humidity control: Maintaining 65-70% RH during warping to ensure consistent yarn properties

We document these parameters for every warp beam produced, creating a database that helps us optimize settings for different yarn types and fabric constructions. This data-driven approach has reduced warp-related bow and skew by 62% in our operation.

How do you verify warp quality before weaving begins?

Never assume your warp is perfect—always verify. Our pre-weaving checklist includes:

- Tension profiling: Measuring tension at 10 points across the beam width

- Visual inspection: Checking for obvious defects, broken ends, or misalignment

- Sample weaving: Running 5-10 meters at production speed to identify issues early

- Yarn count verification: Ensuring consistent linear density across the beam

This 15-minute verification process has saved countless production hours by catching problems before they multiply. As the saying goes in our weaving shed: "An hour of prevention is worth a day of correction."

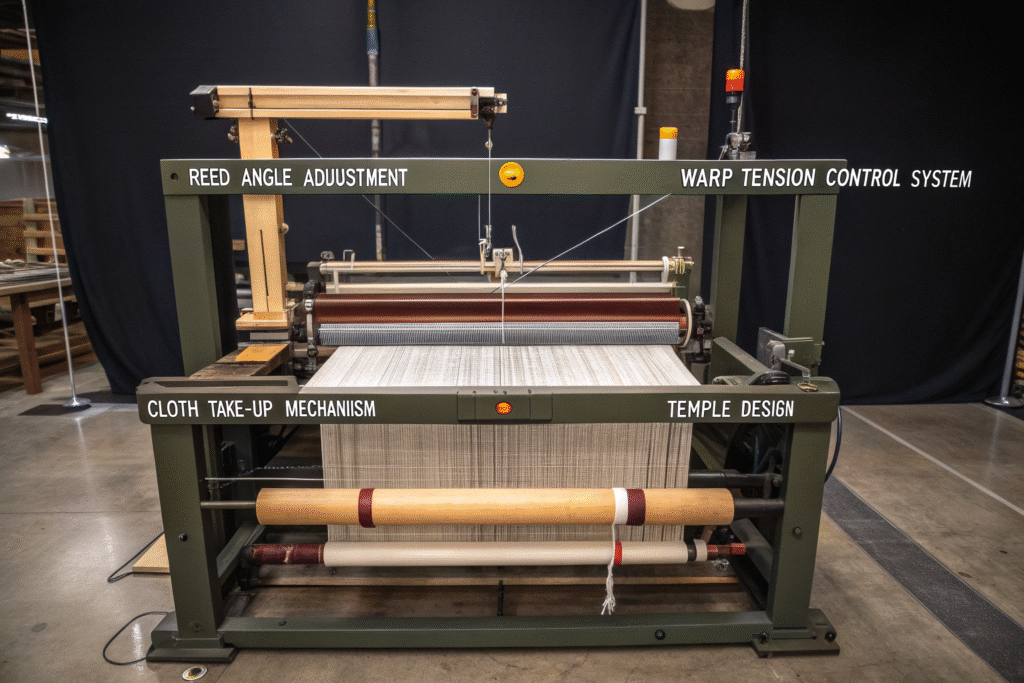

What loom adjustments directly impact bow and skew control?

The loom is where theory meets reality, and precise adjustments make all the difference. Every element from the reed to the take-up mechanism influences fabric straightness. The key is understanding that you're not fighting a single cause but managing multiple interacting factors. At 900 rpm, a misadjustment of just 0.1mm can compound into significant distortion over thousands of picks.

Let me share our systematic approach to loom optimization. We start with basic mechanical alignment—ensuring the reed is perfectly parallel to the breast beam and cloth roll. Then we move to timing adjustments, particularly the beat-up timing relative to shed formation. Finally, we fine-tune tension systems, both warp and cloth take-up. This sequence prevents the frustration of adjusting one parameter only to upset three others. (Here's a trade secret: we mark our optimal settings with paint pens once we achieve perfection—saving hours of recalibration after maintenance.)

How does reed position and beat-up force affect weft alignment?

The reed is your primary tool for controlling weft positioning. Three factors matter most:

- Reed height relative to fell line: Affects where beat-up occurs in the shed cycle

- Reed sway or tilt: Directly creates skew if not perfectly vertical

- Beat-up force consistency: Variations cause uneven weft packing

We use laser alignment tools to verify reed position during style changes. For particularly problematic fabrics, we'll sometimes introduce a deliberate 0.1-0.2° reed tilt to counteract inherent skew tendencies—a technique we developed after six months of experimentation with twill weaves. The results have been dramatic: our denim skew rates dropped from 3.2% to 0.8% after implementing compensated reed positioning.

What role do temples play in maintaining fabric width and straightness?

Temples are the unsung heroes of fabric straightness. These devices at the fabric edges maintain width and prevent contraction that leads to bow. The trick is matching temple type to fabric structure:

- Ring temples for most woven fabrics

- Full-width temples for delicate or high-shrinkage fabrics

- Roller temples for heavy industrial fabrics

We learned the importance of proper temple selection the hard way when weaving a lightweight taffeta for eveningwear. Standard ring temples created visible distortions at the edges, but switching to needle-pin full-width temples eliminated the problem entirely. The cost was higher, but the 30% reduction in seconds quality paid for the upgrade in three months.

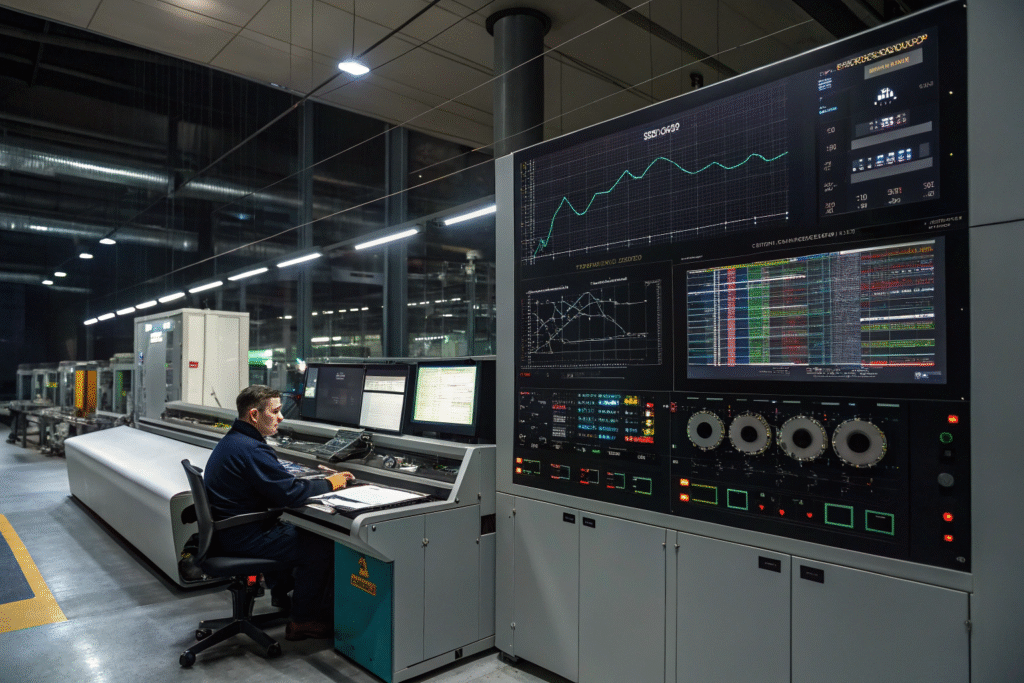

How can real-time monitoring and data analysis prevent defects?

In high-speed weaving, you can't wait for offline inspection to find problems. By the time bow or skew appears in quality control, you've already produced hundreds of defective meters. The solution is continuous monitoring with immediate feedback loops. We've invested in vision systems that analyze weft alignment in real-time, but even simple manual methods can dramatically improve detection and response.

Our most effective innovation has been the "weft angle tracker"—a simple laser line projected across the fabric that makes any deviation immediately visible to operators. Combined with digital protractors that measure weft angle every 50 meters, this low-tech solution catches 90% of developing problems before they exceed tolerance. The data from these measurements feeds into our statistical process control system, triggering alerts when processes show signs of variation.

What statistical methods help predict and prevent bow and skew?

We use three key analytical approaches:

- Process capability analysis (Cpk): Measuring how well our process stays within specification limits

- Trend analysis: Identifying gradual deterioration before it causes defects

- Correlation analysis: Finding relationships between machine parameters and fabric straightness

By applying these methods, we've identified that 73% of bow variations correlate with humidity fluctuations in our weaving shed. This insight led us to install precision HVAC controls, reducing bow variability by 41%. The principles of statistical process control in textile manufacturing provide the foundation for this data-driven approach.

How do you establish effective response protocols?

Monitoring is useless without action. We've created tiered response protocols:

- Alert Level 1 (1-2% deviation): Operator adjustment and increased monitoring

- Alert Level 2 (2-3% deviation): Technician intervention and parameter documentation

- Alert Level 3 (>3% deviation): Production stop and engineering review

This structured approach prevents overreaction to minor variations while ensuring serious issues receive immediate attention. The result has been a 65% reduction in defect escalation—catching problems while they're still correctable.

What fabric-specific strategies address unique challenges?

Different fabrics present different straightness challenges, and your control strategies must adapt accordingly. Lightweight fabrics behave differently from heavy ones, tight weaves differently from loose ones, and natural fibers differently from synthetics. Through twenty years of solving these problems, we've developed specialized approaches for common fabric types.

Let me share some fabric-specific insights. For cotton poplin, the main challenge is skew caused by yarn torque from ring-spun yarns. Our solution involves alternating S and Z twist yarns in the warp. For polyester taffeta, bow is the primary issue due to high tension sensitivity—we run at lower tensions with compensated temple settings. For wool suiting, both bow and skew can develop during finishing, so we weave with deliberate counter-distortion that relaxes to straightness during finishing.

How do finishing processes affect final fabric straightness?

Never assume weaving straightness equals finished fabric straightness. The tensions and moisture applications in finishing can introduce or correct distortions. We work closely with our dyeing and finishing partners to understand how their processes affect our woven fabrics. For instance, we know that stenters can either dramatically improve or destroy fabric straightness depending on how weavers and finishers coordinate.

We developed a "finishing simulation" where we subject woven samples to typical finishing tensions and temperatures to predict final straightness. This allows us to make compensatory adjustments at the weaving stage. A client in Italy who was experiencing 4% skew after printing now receives fabric with 1% counter-skew from us that becomes perfectly straight after their finishing process. This level of coordination requires trust and data sharing, but the quality improvements are remarkable.

What are the most common mistakes in bow and skew control?

From auditing other mills and solving our own problems, we've identified these frequent errors:

- Chasing the problem: Adjusting multiple parameters simultaneously without understanding root causes

- Ignoring environmental factors: Not controlling temperature and humidity

- Inadequate training: Operators who don't understand the relationship between adjustments and results

- Poor maintenance: Worn reeds, faulty temples, and misaligned mechanisms

- Inconsistent measurement: Using different methods or frequencies across shifts

Avoiding these pitfalls requires discipline and systems, but the payoff is fabric quality that commands premium prices and customer loyalty.

Conclusion

Controlling bow and skew in high-speed weaving isn't about finding a single solution—it's about executing a comprehensive system that addresses the issue at every stage: from perfect warp preparation through precisely adjusted looms to real-time monitoring and fabric-specific strategies. The mills that master this integration don't just produce straighter fabric; they operate with higher efficiency, lower waste, and greater profitability.

The straight truth is that bow and skew control represents one of the most significant opportunities for quality and cost improvement in modern weaving. The methods we've developed through years of trial and error—documenting parameters, establishing response protocols, and coordinating with finishing partners—have transformed our fabric quality and customer satisfaction.

If you're ready to straighten out your weaving operation and produce fabric that meets the most demanding quality standards, let's put these principles into practice. We can share specific parameter settings, monitoring techniques, and troubleshooting guides tailored to your equipment and fabric types. For technical assistance in optimizing your weaving process, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's weave perfection together, one straight meter at a time.