As a textile engineer specializing in stretch fabrics for over twenty years, I've seen more brands get spandex testing wrong than almost any other fabric property. The consequences are real: I've witnessed entire activewear collections develop permanent bagging after just a few wears, and swimwear that lost its shape by mid-season. Proper heat-set testing isn't just a quality check—it's predicting how your fabric will perform through the entire lifecycle of the garment.

Spandex heat-setting is the thermal process that stabilizes the fabric and "programs" the elastic memory. When done correctly, it ensures the fabric returns to its original dimensions after stretching. The testing must evaluate both immediate recovery (how quickly it snaps back) and growth (the permanent deformation that accumulates over time). At our CNAS-certified lab, we've developed a comprehensive testing protocol that has helped brands reduce stretch-related returns by up to 65% by identifying heat-setting issues before production.

Let me walk you through the exact testing methodology we use to predict real-world spandex performance.

What are the key performance indicators for spandex durability?

Understanding what to measure is the foundation of effective spandex testing. The critical performance indicators extend beyond simple stretch percentage to how the fabric behaves through repeated stress cycles and how it recovers over time.

The essential metrics include: immediate recovery percentage, permanent growth percentage, stress decay (loss of compression force), and hysteresis (energy loss during stretch cycles). Each of these indicators tells a different story about how the spandex will perform in garments. We recently worked with a compression wear brand that was only testing stretch percentage—when we introduced full recovery testing, we discovered their fabric had 28% permanent growth after just 20 stretch cycles, explaining why their garments were bagging out so quickly.

How do you measure permanent growth accurately?

Permanent growth measures the irreversible elongation that occurs after stretching and recovery. The standard test involves stretching fabric to a specified extension, holding for a set time, releasing, and then measuring how much longer the fabric is compared to its original length.

The ASTM D3107 test method is the industry standard, but we've enhanced it with additional cycles to better simulate real-world use. Our protocol involves: marking a 100mm gauge length, stretching to 80% of breaking elongation (typical for activewear), holding for 30 seconds, releasing, waiting 60 seconds for recovery, then measuring the new length. We repeat this for 1, 10, and 50 cycles to track growth accumulation. A yoga wear brand discovered through this testing that their fabric showed acceptable 3% growth after 1 cycle but concerning 14% growth after 50 cycles—catching this before production saved them from what would have been massive returns.

What does hysteresis reveal about energy efficiency?

Hysteresis measures the energy loss during stretch and recovery cycles—essentially, how much work the fabric loses as heat during movement. High hysteresis means the fabric feels "tired" and requires more energy from the wearer during athletic activity.

We test hysteresis using a constant-rate-of-extension machine that measures the area between the stretch and recovery curves. Optimal performance fabrics show hysteresis below 25%, while anything above 35% indicates potential comfort issues. A running apparel brand used this data to reformulate their fabric, reducing hysteresis from 38% to 22% and receiving unsolicited feedback about improved comfort during long-distance runs. The ASTM D4964 tension and elongation test standard provides the framework for these measurements.

How does heat-setting temperature affect recovery performance?

Heat-setting temperature is the most critical variable in spandex performance—too low, and the fabric won't stabilize properly; too high, and you degrade the spandex fibers. Finding the optimal temperature range for your specific spandex type and fabric construction is essential for consistent performance.

Different spandex types have different optimal heat-setting ranges: conventional spandex typically sets at 180-195°C, while heat-resistant varieties can withstand 195-210°C. The dwell time (typically 30-90 seconds) interacts with temperature, creating a cumulative thermal profile that determines the final stabilization. We recently helped a swimwear brand identify that their manufacturer was using 175°C—below the optimal range for their spandex type—resulting in 22% growth after chlorinated water exposure instead of the 8% their fabric was capable of achieving.

What's the optimal temperature range for common spandex types?

Based on our testing of thousands of fabric samples, here are the proven heat-setting ranges for different spandex applications:

| Spandex Type | Optimal Temperature Range | Typical Applications | Performance Notes |

|---|---|---|---|

| Conventional Spandex | 180-195°C | Everyday activewear, leggings | Good recovery up to 160°C wash |

| Heat-Resistant Spandex | 195-210°C | Swimwear, performance compression | Maintains recovery after repeated heating |

| High-Tenacity Spandex | 185-200°C | Athletic compression, medical | Superior growth resistance |

| Eco-Friendly Spandex | 175-190°C | Sustainable collections | Often more temperature-sensitive |

A dancewear manufacturer discovered their conventional spandex was being heat-set at 205°C—above its maximum tolerance—causing a 40% reduction in recovery force after just five launderings. Adjusting to 190°C extended the garment's functional life by approximately 60%.

How can you verify proper heat-setting in production?

Verifying that your manufacturer maintains consistent heat-setting requires both process monitoring and finished fabric testing. We recommend: infrared temperature guns to verify oven temperatures, data loggers to track thermal profiles through the oven, and periodic testing of recovery and growth from production rolls.

We implemented a statistical process control system for a leggings brand that reduced their recovery performance variation from ±18% to ±6% across production batches. The system included daily verification samples tested for growth and recovery, with any deviation outside control limits triggering immediate oven calibration. This approach virtually eliminated the inconsistent performance that had plagued their previous production runs.

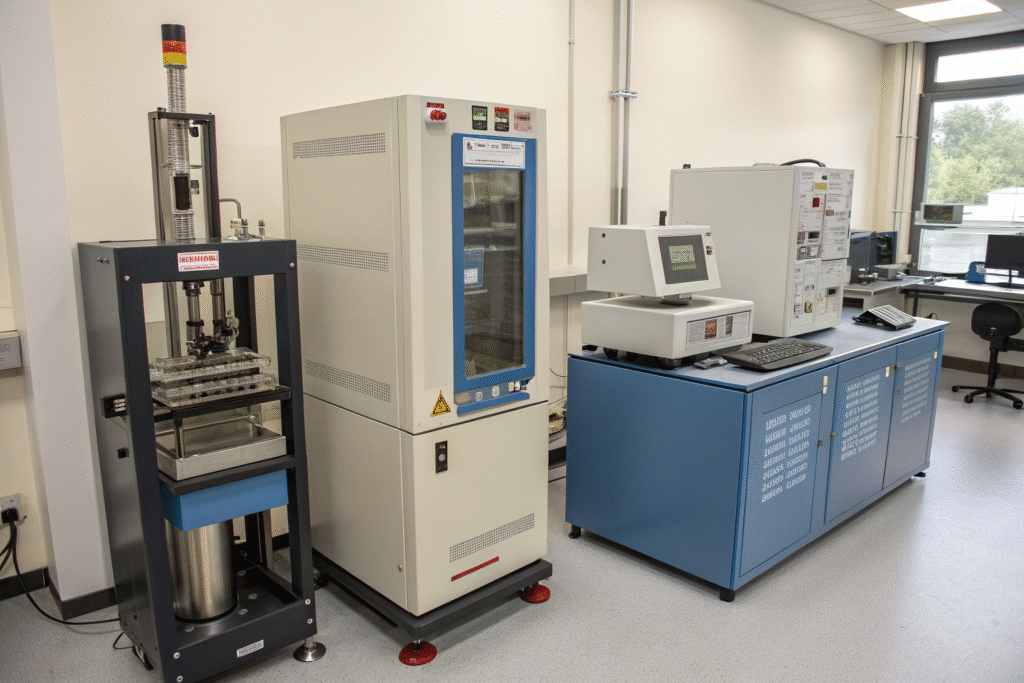

What testing equipment delivers reliable spandex results?

The right testing equipment is non-negotiable for accurate spandex evaluation. Basic tensile testers can measure some properties, but specialized equipment provides the cycling, control, and measurement precision needed for predictive testing.

Essential equipment includes: constant-rate-of-extension machines with cycling capability, sample conditioning chambers (for standardized temperature and humidity), precision marking tools, and recovery jigs for consistent measurement. Our lab uses machines capable of programmed cyclic testing with force measurement accuracy of ±0.5% and extension accuracy of ±0.2mm—this precision is necessary to detect the subtle differences that separate adequate from excellent spandex performance.

How does cyclic testing simulate real-world conditions?

Cyclic testing repeatedly stretches and releases fabric to simulate the wear patterns garments experience during use. The number of cycles, extension percentage, and recovery time should match the intended end use.

Our standard protocols include:

- Activewear: 50 cycles to 80% extension with 30-second recovery

- Swimwear: 20 cycles to 100% extension with 60-second recovery (simulating water saturation)

- Intimate apparel: 30 cycles to 60% extension with 10-second recovery

- Medical compression: 100 cycles to 50% extension with minimal recovery time

A sports bra manufacturer discovered through cyclic testing that their fabric maintained excellent recovery for the first 15 cycles but then deteriorated rapidly—redesigning their fabric construction to address this specific fatigue point reduced their warranty claims by 34%.

What environmental factors affect test results?

Temperature and humidity significantly impact spandex performance, so standardized conditioning is essential. The industry standard is 21±1°C and 65±2% relative humidity, with samples conditioned for 24 hours before testing.

We've documented that variations outside these parameters can alter results by 12-18%—enough to mask significant performance issues. A client was getting inconsistent results between their facility and their manufacturer's until we discovered 15% humidity difference was causing the variation. Implementing proper conditioning standardized their measurements and eliminated the conflicts. The standard textile testing conditioning requirements provide the complete protocol.

How do you interpret test results for different applications?

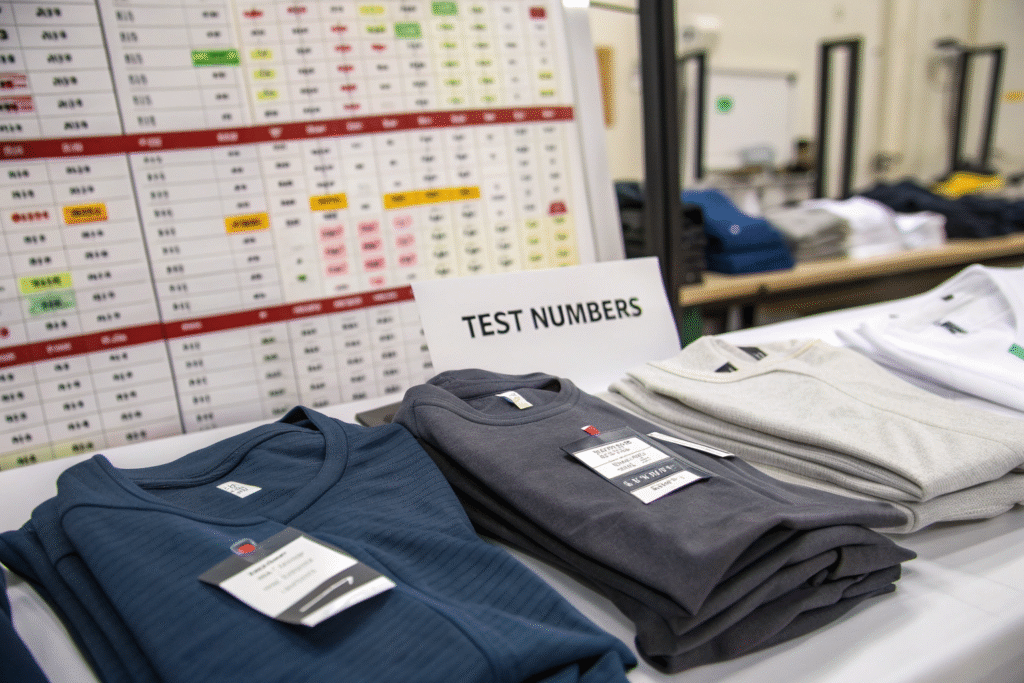

Test numbers alone don't tell the whole story—interpretation must consider the specific garment application, wear expectations, and care conditions. What constitutes acceptable performance varies dramatically between, for example, compression wear versus loungewear.

We use application-specific performance benchmarks:

- Compression wear: <3% permanent growth after 50 cycles

- Athletic apparel: <6% permanent growth after 50 cycles

- Everyday stretch: <8% permanent growth after 30 cycles

- Fashion stretch: <12% permanent growth after 20 cycles

A luxury activewear brand initially rejected a fabric showing 5.2% growth—until we demonstrated this actually outperformed their current fabric's 7.8% and was excellent for their application category.

What growth percentage indicates problematic performance?

As a general rule, permanent growth exceeding 8% after 30 cycles indicates potential bagging issues in most activewear applications. Growth between 8-12% may be acceptable for fashion items with limited stretch demands, while anything above 12% typically signals significant durability concerns.

We recently helped a jeans manufacturer identify that their stretch denim showed 15% growth—explaining why their customers reported knee bagging after just one month of wear. Reformulating their spandex blend and optimizing heat-setting reduced growth to 6%, dramatically improving garment longevity.

How does recovery percentage correlate with garment fit?

Recovery percentage indicates how completely fabric returns to its original dimensions after stretching. For body-hugging garments, we recommend minimum 92% immediate recovery and 96% after 60 minutes for optimal fit retention.

A yoga brand was experiencing consistent size complaints despite strict pattern specifications—testing revealed their fabric had only 87% immediate recovery, causing garments to feel tighter initially before relaxing to the proper size. Improving recovery to 94% eliminated the sizing confusion and reduced returns by 28%.

Conclusion

Proper spandex heat-set testing requires a comprehensive approach that evaluates both immediate recovery and permanent growth through standardized cyclic testing under controlled conditions. By understanding the relationship between heat-setting parameters and performance outcomes, and interpreting results in the context of your specific application, you can predict real-world fabric behavior before committing to production.

The investment in thorough spandex testing pays dividends in reduced returns, improved customer satisfaction, and stronger brand reputation for quality. If you need help establishing a spandex testing protocol or verifying your current fabric's performance, contact our Business Director Elaine at elaine@fumaoclothing.com. Our technical team will ensure your stretch fabrics deliver the durability and recovery your customers expect.