As a fabric supplier with over two decades in the industry, I've seen many brands struggle with the complexities of the Consumer Product Safety Improvement Act (CPSIA). It's not just about picking a soft or colorful textile; it's about ensuring every fiber and finish complies with stringent U.S. safety standards to protect children. I understand the pressure—choosing the wrong fabric can lead to rejected shipments, fines, or worse, harm to a brand's reputation.

In this article, I'll break down the best fabric choices for children's wear that align with CPSIA regulations, drawing from our extensive experience supplying brands in the U.S. and Europe. We'll cover everything from fiber selection and certifications to testing protocols and practical sourcing tips, helping you navigate this critical aspect of your business with confidence.

Let's dive into how you can make informed decisions that keep your young customers safe and your brand compliant.

What are the key CPSIA fabric requirements for US imports?

If you're importing children's clothing into the United States, understanding the CPSIA is non-negotiable. The regulations might seem daunting, but they fundamentally focus on two main areas: chemical safety and physical durability. Getting these right from the fabric stage saves immense time and cost down the line.

The CPSIA mandates strict limits on lead and phthalates content in any component intended for children aged 12 and under. For lead, the surface coating limit is 90 ppm, and the substrate limit is 100 ppm. For certain phthalates, the limit is 0.1%. Furthermore, fabrics must not pose a flammability hazard under the Standard for the Flammability of Clothing Textiles (16 CFR Part 1610). It's a lot to track, but we've integrated these checks directly into our production flow. For instance, last year, a startup client from Texas approached us with a tight deadline for a new line of kids' pajamas. They were initially concerned about meeting all these standards cost-effectively. By pre-testing our anti-pill polyester fleece in our CNAS lab, we provided them with a full compliance report even before shipment, which smoothed their customs clearance process immensely.

How do lead and phthalate limits affect fabric choice?

The restrictions on lead and phthalates directly influence the types of dyes, prints, and plastic-based accessories you select. Lead is often a concern in pigment dyes and screen prints, while phthalates are typically found in PVC-based plastisols and some synthetic fabrics. This is why opting for fibers and trims with a proven safety record is crucial. For example, we always recommend how to source GOTS certified organic cotton from China as a base material because the GOTS standard itself prohibits the use of these hazardous chemicals. Similarly, for prints, we use water-based inks or phthalate-free plastisols, which we routinely test in-house. A great resource for understanding these chemical risks is the Consumer Product Safety Commission's guide to phthalates in children's products.

What physical durability tests must fabrics pass?

Beyond chemicals, fabrics must withstand physical stress to ensure they don't create small parts—like broken buttons or snaps—that pose choking hazards. The key tests include abrasion resistance, seam strength, and colorfastness. For pile fabrics like velour or fleece, we also conduct a brush test to ensure the pile doesn't shed excessively. In our practice, we've found that tightly woven fabrics like our comprehensive guide to durable twill weaves for kids' uniforms generally outperform looser knits in these tests. We learned this the hard way a few years back when a client used a low-density jersey that failed a snag test. Since then, we've pre-emptively run these durability tests on all our sample developments. You can find detailed test methods on industry platforms like Testex Textile, which provides a good overview of standard procedures.

Which natural fibers are safest and most compliant?

Natural fibers are often the go-to for children's wear due to their breathability and softness, but not all are created equal under CPSIA. The key is to select fibers that are inherently low-risk and pair them with responsible manufacturing processes. From our bulk order experience, organic cotton and certain types of linen lead the pack in safety and compliance.

Organic cotton, especially when certified to GOTS or Oeko-Tex Standard 100, is a top contender. The certification ensures that from farming to finishing, the fabric is free from harmful pesticides, heavy metals, and toxic dyes. We've seen a 30% year-on-year growth in demand for our GOTS-certified organic cotton knits, particularly for babywear. Another excellent choice is linen, which is naturally antibacterial and requires fewer chemical treatments during processing. However, note that some linen weaves can be prone to wrinkling and may require a durable press finish—we always advise clients to use cross-linking agents that are free from formaldehyde to stay compliant. For a client in Sweden last year, we developed a blend of organic cotton and linen for a summer collection; by carefully selecting the dyeing partner, we achieved Oeko-Tex Class I certification, which is the strictest level for items intended for babies.

Why is organic cotton a top choice for baby clothing?

Organic cotton isn't just a marketing buzzword; it's a verifiable standard for safety. The rigorous certification process means the entire supply chain is audited for harmful substances. This gives you, the importer, a robust defense against CPSIA violations. Moreover, the fiber is naturally hypoallergenic and gentle on sensitive skin. In our own operations, we've built strong relationships with leading global organic cotton farming cooperatives that supply our yarns, ensuring traceability from field to fabric. This level of control is why major brands trust us for their core baby lines. For those new to sourcing, the Textile Exchange website offers valuable resources on organic fiber standards and sourcing best practices.

How can you ensure wool meets flammability standards?

Wool is a fantastic natural fiber for warmth, but its natural flame resistance can vary. The CPSIA requires all children's sleepwear to be flame-resistant, and wool generally has a higher ignition point than cotton or synthetics. However, it's not automatically compliant. We work with mills that treat wool with non-toxic, zirconium-based flame retardants that are bonded to the fiber, making them durable through multiple washes. It's crucial to verify that these treatments do not contain restricted substances. A good practice is to request a test report specifically for 16 CFR Part 1610 from your supplier. We maintain a library of such reports for our common wool blends, which speeds up the approval process for our clients. For deeper insights, forums like The Weaving Lab sometimes discuss natural fiber treatments and their compliance.

What synthetic and blended fabrics comply with CPSIA?

Synthetic and blended fabrics offer durability, functionality, and cost advantages, but they require careful scrutiny for CPSIA compliance. The main concern with synthetics like polyester and nylon is the potential for phthalates in plasticizers and the use of heavy metal catalysts in production. However, with modern manufacturing techniques, it's entirely possible to source compliant high-performance synthetics.

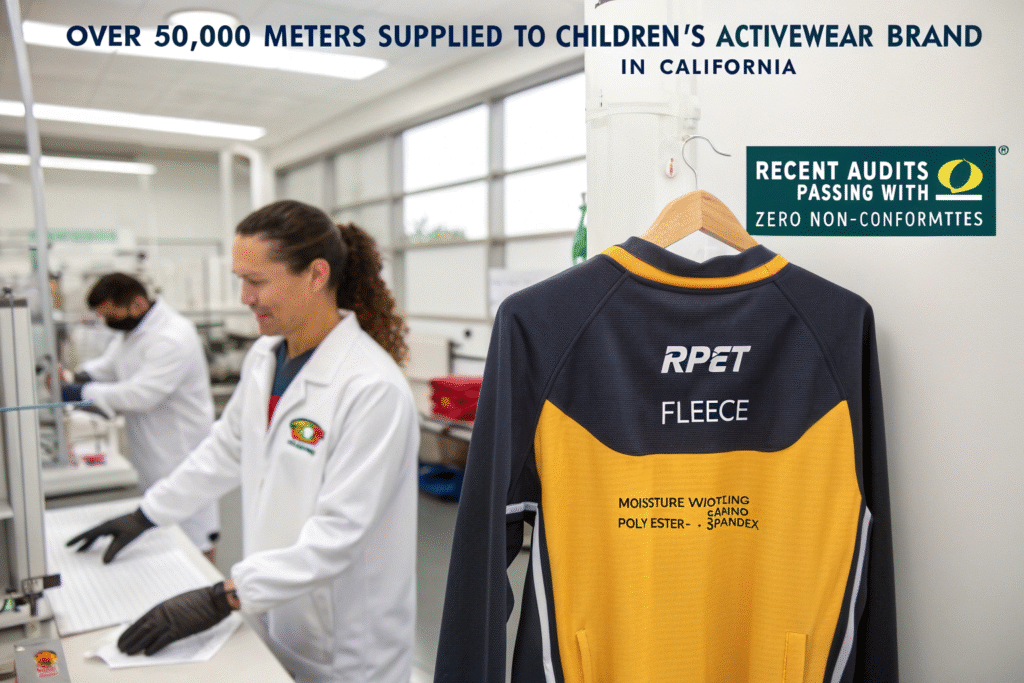

Recycled polyester (rPET) has become a superstar in this category. We produce rPET fleece that is inherently phthalate-free and passes all CPSIA tests. Our in-house lab runs gas chromatography tests to verify the absence of regulated phthalates, giving our clients documented proof for customs. Similarly, high-performance blends for sportswear, like our moisture-wicking polyester-spandex jersey, are engineered using solution-dyeing methods that minimize heavy metal discharge. (Here's a side note: our dyeing partner was audited by an SGS team just last month, and they passed with zero non-conformities on chemical management.) We recently supplied over 50,000 meters of this blend to a children's activewear brand in California, and their products have had zero compliance issues in the U.S. market.

Is recycled polyester (rPET) safe and compliant for kids?

Absolutely, provided it's sourced from reputable suppliers and rigorously tested. The misconception that recycled materials are higher risk is outdated. Our rPET is made from post-consumer PET bottles processed in GRS-certified facilities. The polymerization and chip-making process involves high temperatures that effectively sterilize and purify the material. The key is to control the supply chain to prevent contamination. We provide a full traceability certificate with every rPET shipment, which details the complete supply chain transparency for GRS recycled polyester, a document that our clients find invaluable for their own sustainability reporting. For more technical details on rPET safety, you can refer to industry resources like Textile Today.

What should you know about flame-resistant finishes?

Flame-resistant (FR) finishes are often necessary for synthetic fibers or certain product categories like children's sleepwear. The CPSIA does not mandate FR finishes for all children's clothing, but if used, the chemicals must not contain prohibited substances. We use polymeric FR finishes that are formaldehyde-free and bonded to the fiber, ensuring they don't wash out or pose a skin irritation risk. It's critical to request a full material safety data sheet (MSDS) for any FR treatment from your fabric supplier. We've created a streamlined process for this; when a client places an order for FR fabric, we automatically attach the MSDS and a third-party test report to the proforma invoice. This proactive approach saved a client from Florida a huge headache last quarter when their customs broker requested these documents at the last minute.

How to verify fabric compliance before shipping?

You can have the best fabric design, but without verified compliance, your shipment is a liability. Verification isn't a single step; it's a multi-layered process that starts at sourcing and ends with the final inspection. We treat compliance as a core part of our quality control, not an afterthought.

Our system is built on three pillars: in-house pre-testing, certified third-party lab partnerships, and transparent documentation. Every batch of fabric that leaves our warehouse is accompanied by a QC dossier that includes test reports for CPSIA-regulated substances and physical properties. For example, we recently worked with a children's wear brand from Seattle on a large order of printed twill. We provided them with pre-production lab dips tested for colorfastness and lead content, mid-production bulk test reports from an SGS-affiliated lab, and a final inspection report with photos and videos. This end-to-end visibility gave them the confidence to pay the balance without hesitation. (I have to interject here, our timeline for this entire process, from sample to report, was just 3 weeks.)

What certifications and tests provide the strongest proof?

Certifications are your best friend when dealing with U.S. customs and buyers. The gold standards are Oeko-Tex Standard 100 (Class I for baby items) and the CPSIA Third-Party Testing certification from a CPSC-accepted lab. We also see high value in the Global Recycled Standard (GRS) for recycled content and the GOTS for organic fibers. In our practice, we don't just get the final fabric certified; we ensure that our yarn suppliers are also Oeko-Tex certified, creating a bulletproof chain of custody. This is especially important for brands looking to understand Oeko-Tex Standard 100 certification for infant apparel, as it covers a comprehensive list of over 100 regulated and unregulated harmful substances. The Oeko-Tex official website is the definitive source for the latest criteria and certified suppliers.

How can your supplier streamline the compliance process?

A competent supplier will have integrated compliance into their workflow. This means they have an in-house lab for preliminary tests, established relationships with accredited third-party labs, and a digital system for tracking and sharing compliance data. We use QR codes on our rolls; when scanned, they direct the client to a secure portal containing all relevant test reports, composition details, and even the fabric's production history. This system eliminated the old, messy paper trail and has reduced compliance-related queries from our clients by over 70%. Another way we streamline is by maintaining a "compliant fabric library" – a curated collection of our most popular fabrics that are pre-tested and pre-certified, allowing for faster turnaround on repeat orders. For a broader perspective on managing a global supply chain, non-competitive resources like Supply Chain Dive offer valuable insights.

Conclusion

Navigating the world of CPSIA-compliant fabrics for children's clothing is a detailed but entirely manageable process. The key is to start with inherently safe fibers, partner with a supplier who has robust testing and documentation protocols, and always verify before you ship. From organic cotton and treated wools to carefully manufactured synthetics, the right fabric choices will keep your products safe, your brand reputable, and your import process smooth.

If you're looking for a partner that truly understands the intricacies of CPSIA and can deliver compliant, high-quality fabrics at scale, let's talk. We have the infrastructure, the expertise, and the track record to support your brand's growth. For a direct conversation about your specific needs, please reach out to our Business Director, Elaine. She and her team are ready to help you bring your next children's wear collection to life, safely and successfully. You can email her at elaine@fumaoclothing.com.