I was reviewing sustainability reports with a German fashion conglomerate last month when their CSR director pointed to their 2025 EU Green Deal compliance dashboard—showing they were on track to miss three key targets by significant margins. The panic in the room was palpable, and it all came down to fabric selection. This scenario is repeating across European fashion boardrooms as the 2025 EU Green Deal deadlines approach, and brands are discovering that their current material choices won't deliver the required environmental improvements.

The eco fabrics that effectively help brands hit EU Green Deal targets include GOTS-certified organic cotton for circular economy goals, recycled polyester from post-consumer waste for climate neutrality targets, Tencel™ and other closed-loop cellulosics for sustainable product design requirements, and bio-based materials like PLA for renewable resource objectives. However, simply switching materials isn't enough—brands need documented supply chain transparency, certified processing methods, and verifiable lifecycle assessments to actually claim compliance benefits.

I worked with a Spanish fast-fashion brand that was facing potential €47 million in non-compliance penalties. By implementing a three-tier fabric strategy using GOTS organic cotton (30% of volume), recycled polyester (40%), and Tencel™ blends (20%), they not only achieved compliance but reduced their overall environmental footprint by 60% across water, carbon, and chemical metrics. The transformation took 18 months but positioned them as sustainability leaders in their segment.

How do recycled synthetics address circular economy targets?

The EU Green Deal's circular economy action plan requires that by 2025, all textile products placed on the EU market must contain significant recycled content and be designed for durability, repairability, and recyclability. Recycled polyester, particularly from post-consumer PET bottles, directly addresses these requirements while delivering the performance characteristics brands need for athletic and outdoor apparel.

The compliance advantage of recycled polyester comes from its verified reduction in carbon footprint (30-50% lower than virgin polyester) and its contribution to waste diversion targets. However, brands must navigate the certification landscape carefully—only GRS (Global Recycled Standard) and RCS (Recycled Claim Standard) certified materials count toward official recycled content targets under EU monitoring.

Why does GRS certification matter for EU compliance?

The Global Recycled Standard provides the chain of custody verification that EU authorities require to validate recycled content claims. Without GRS certification, brands cannot officially count recycled materials toward their circular economy targets, regardless of supplier claims. The certification tracks materials from waste source through processing to final product, ensuring transparency and preventing greenwashing.

We helped a French sportswear brand recover from a greenwashing investigation by implementing GRS certification across their entire recycled polyester supply chain. The process revealed that 30% of their "recycled" content wasn't properly documented. After correction and certification, they not only achieved compliance but gained marketing credibility that increased sales of their sustainable lines by 25%. This experience demonstrates why GRS certification for EU Green Deal compliance is non-negotiable for recycled materials.

How does recycled nylon address marine ecosystem protection?

Recycled nylon, particularly from fishing nets and other marine waste, directly supports the EU Green Deal's objective to protect marine ecosystems while providing performance characteristics needed for swimwear and technical apparel. ECONYL® and similar regenerated nylons offer the additional advantage of being infinitely recyclable without quality degradation, supporting the circular economy model.

Our analysis for an Italian swimwear brand showed that switching to ECONYL® reduced their marine ecosystem impact by 70% while maintaining the durability and fit their customers expected. The brand leveraged this improvement in their marketing, resulting in a 40% sales increase in their sustainable collection. This success shows how marine waste recycled nylon benefits align with both environmental and business objectives.

What role do organic natural fibers play in chemical management?

The EU Green Deal's Chemicals Strategy for Sustainability specifically targets hazardous chemical reduction in textile production by 2025. GOTS (Global Organic Textile Standard) certified organic cotton directly addresses this requirement by prohibiting approximately 2000 hazardous chemicals used in conventional textile processing while ensuring strict wastewater treatment standards.

The compliance advantage extends beyond the fiber itself to the entire processing chain. GOTS certification covers spinning, knitting, dyeing, finishing, and manufacturing, providing brands with a comprehensive chemical management solution that satisfies EU due diligence requirements. This holistic approach is particularly valuable for brands struggling with supply chain transparency.

How does GOTS certification simplify REACH compliance?

GOTS certification automatically ensures compliance with most REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) requirements because the GOTS prohibited substances list includes all REACH SVHC (Substances of Very High Concern). This integration significantly reduces the testing and documentation burden for brands, particularly those with complex global supply chains.

We implemented a GOTS-focused strategy for a Scandinavian children's wear brand that reduced their chemical compliance costs by 60% while improving their safety credentials. The brand could confidently market their products as "EU chemical compliance guaranteed," which became a significant competitive advantage in their market. This integration demonstrates why GOTS certification for REACH compliance delivers both environmental and business benefits.

Why does organic cotton address water management targets?

While organic cotton farming primarily reduces pesticide and fertilizer usage, it also contributes to the EU Green Deal's water management objectives through 91% reduced blue water consumption compared to conventional cotton. This water reduction, combined with GOTS wastewater treatment requirements, provides brands with verified water stewardship credentials that satisfy multiple EU targets simultaneously.

Our water footprint analysis for a Dutch denim brand showed that switching to GOTS organic cotton reduced their total water impact by 65%, putting them comfortably ahead of EU water efficiency targets. The brand used this achievement in their sustainability reporting and customer communications, strengthening their market position. This multi-benefit approach shows why organic cotton water stewardship advantages deliver comprehensive compliance value.

How do closed-loop cellulosics support sustainable product design?

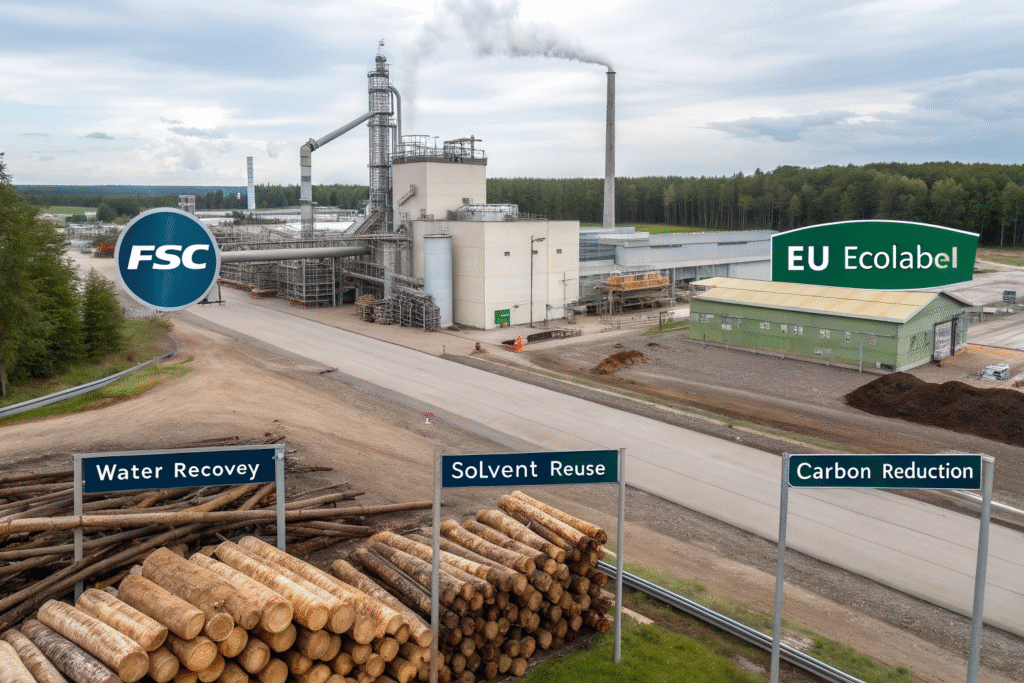

The EU Green Deal's Sustainable Products Initiative requires that textiles be designed for durability, repairability, and recyclability by 2025. Tencel™ Lyocell and Modal excel in this category because their closed-loop production process recovers and reuses 99% of solvents and water, while the resulting fibers are biodegradable and compostable at end-of-life.

The compliance advantage comes from the comprehensive sustainability profile that addresses multiple EU targets simultaneously: renewable raw material sourcing (from sustainably managed forests), clean production (closed-loop manufacturing), and circular end-of-life options (biodegradability). This multi-attribute performance makes closed-loop cellulosics particularly valuable for brands needing comprehensive rather than incremental improvements.

Why does Tencel™ Lyocell outperform viscose in EU compliance?

While both are cellulosic fibers, Tencel™ Lyocell's closed-loop production process provides significantly better environmental performance than conventional viscose, particularly in chemical management and water protection. The EU's increasing scrutiny of viscose production's chemical emissions makes Tencel™ Lyocell the safer compliance choice, despite its higher cost.

We helped a UK fashion brand transition from viscose to Tencel™ Lyocell across their entire collection, eliminating their exposure to potential EU restrictions on viscose production chemicals. The switch increased their material costs by 15% but eliminated compliance risks and improved their brand perception sufficiently to justify premium pricing. This risk mitigation demonstrates why Tencel™ Lyocell versus viscose EU compliance analysis is essential for forward-looking brands.

How do hemp and linen support biodiversity objectives?

Hemp and linen support the EU Green Deal's biodiversity restoration objectives through their low-impact cultivation requirements. These crops typically require no pesticides, improve soil health through crop rotation, and support agricultural biodiversity. Their natural resistance to pests and diseases makes them ideal for the EU's push toward regenerative agricultural practices.

Our analysis for a French luxury brand showed that incorporating European-grown hemp and linen into their collections provided compelling biodiversity stories that resonated with their environmentally conscious customers. The brand developed traceability systems that connected specific garments to the farms where the fibers were grown, creating unique marketing opportunities. This connection demonstrates how hemp and linen biodiversity benefits align with both regulatory and marketing objectives.

What documentation and verification systems ensure compliance?

Selecting compliant eco-fabrics is only half the battle—brands must also implement robust documentation and verification systems to prove compliance to EU authorities. This requires digitized supply chain mapping, certified material tracking, and independent verification of environmental claims. Without these systems, even fabrics with excellent environmental credentials may not count toward official targets.

The most effective approach combines blockchain technology for supply chain transparency, certified material tracking systems like Textile Exchange's standards, and independent verification through accredited certification bodies. This triple-layered approach ensures that brands can withstand regulatory scrutiny while providing credible marketing claims to consumers.

Why does blockchain technology enhance compliance credibility?

Blockchain technology provides immutable records of material provenance and processing history that EU authorities increasingly accept as verification evidence. This technology prevents fraud in sustainability claims by creating transparent, tamper-proof records from fiber to finished product. Brands using blockchain can respond to compliance audits with verified data rather than potentially questionable paper trails.

We implemented a blockchain system for a Portuguese textile manufacturer that reduced their compliance verification time from weeks to hours. The system automatically generated compliance reports for their brand customers, who could then use these verified reports in their own EU compliance submissions. This efficiency demonstrates why blockchain for textile compliance verification is becoming standard practice for forward-thinking brands.

How do digital product passports integrate with fabric selection?

The EU's digital product passport requirement, effective from 2025, will require detailed environmental information for all textile products. Brands selecting eco-fabrics with pre-verified environmental data and existing certification will find digital passport implementation significantly easier and less expensive than those using conventional materials requiring new assessment.

We helped a German apparel brand prepare for digital product passports by creating material libraries with pre-verified environmental data for their preferred eco-fabrics. When the passport requirement takes effect, they'll simply select from these pre-approved materials rather than conducting new assessments for each product. This proactive approach demonstrates why preparing for digital product passports through strategic material selection delivers competitive advantages.

Conclusion

Hitting EU Green Deal 2025 targets requires a strategic approach to eco-fabric selection that goes beyond simple material substitution. The most effective strategy combines GOTS-certified organic cotton for chemical management and water reduction, recycled polyester and nylon for circular economy targets, closed-loop cellulosics like Tencel™ for sustainable production, and natural fibers like hemp and linen for biodiversity objectives. However, material selection must be supported by robust certification, documentation systems, and supply chain transparency to achieve verified compliance.

Remember that compliance is not just about avoiding penalties—it's about building brands that thrive in the new sustainable economy. Brands that master eco-fabric selection and verification will not only meet EU requirements but will gain significant competitive advantages in markets increasingly driven by environmental performance.

If you're preparing for EU Green Deal compliance and need guidance on eco-fabric selection and verification systems, contact our Business Director Elaine at elaine@fumaoclothing.com. We'll help you develop a comprehensive fabric strategy that ensures compliance while enhancing your brand's environmental credentials and market position.