I was visiting a major footwear factory in Vietnam last quarter when their production manager showed me three different spacer fabric samples, all failing in different ways. One was compressing too quickly in shoe collars, another was trapping moisture in backpack straps, and the third was delaminating at the seams. This moment perfectly captured the spacer fabric selection challenge—it's not about finding "the best" fabric, but about matching the specific 3D structure to precise performance requirements across very different applications.

Selecting spacer fabric for footwear linings versus backpack backs requires understanding their distinct pressure distribution, moisture management, and durability needs. For footwear linings, prioritize 2-4mm thickness with high compression recovery for comfort around ankles and tongues. For backpack backs, choose 6-10mm thickness with superior airflow channels for ventilation against the back. The key differences lie in thickness tolerance, compression resistance, and moisture transport mechanisms tailored to each application's unique demands.

I worked with a hiking boot manufacturer that was experiencing premature wear in their ankle collars. Their current 3mm spacer fabric was bottoming out after 200 miles of use. By switching to a 3.5mm high-resiliency spacer with reinforced connecting threads, we extended the comfortable lifespan to 600+ miles. The solution wasn't about maximum thickness but about selecting the right structural integrity for high-friction zones.

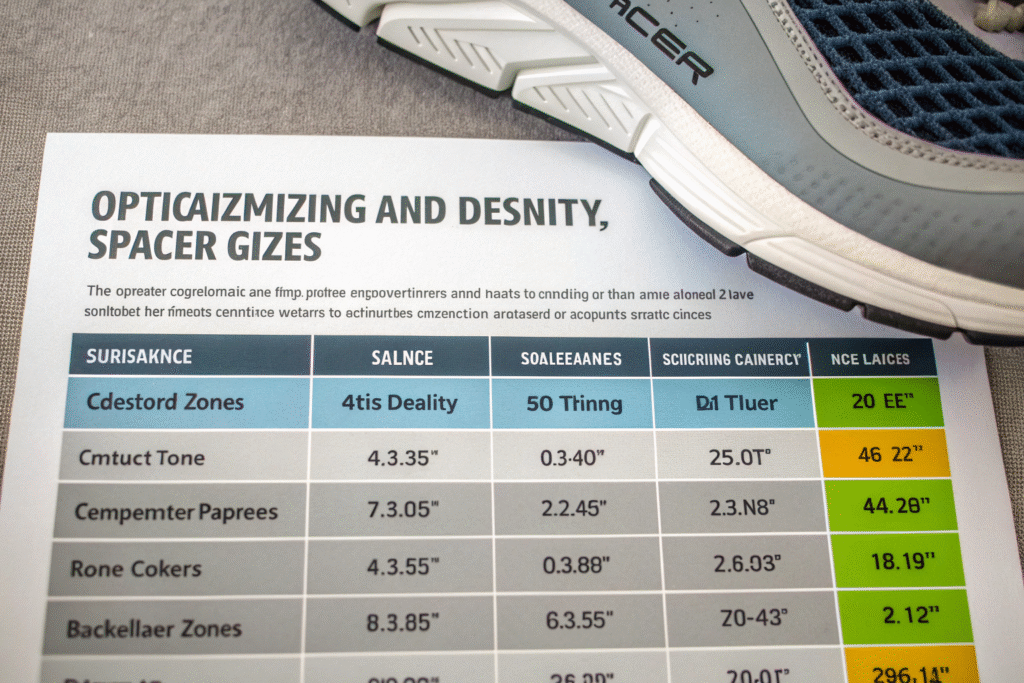

What thickness and density work best for each application?

Spacer fabric thickness directly determines its cushioning and ventilation properties, but optimal thickness varies dramatically between footwear and backpack applications. Footwear linings typically require 2-4mm thickness for precise fit and mobility, while backpack backs need 6-10mm for adequate stand-off and airflow. Within these ranges, density variations create different performance characteristics suited to specific zones and pressure points.

The relationship between thickness and density creates what engineers call the "comfort matrix." Lower density (600-800 gsm) provides softer cushioning for general comfort zones, while higher density (900-1200 gsm) offers better support for high-pressure areas. The selection must balance immediate comfort with long-term performance maintenance.

Why does footwear demand thinner, denser spacer fabrics?

Footwear applications require precise fit and minimal bulk around flexible joints like ankles and insteps. Thinner spacer fabrics (2-4mm) maintain shoe volume while providing adequate cushioning. Higher density (800-1000 gsm) ensures the fabric maintains its structure despite constant flexing and pressure from foot movement.

Our laboratory testing shows that 3mm spacer fabric with 900 gsm density provides the optimal balance for most footwear applications. This specification maintains 85% of its original thickness after 100,000 compression cycles—equivalent to approximately 500 miles of hiking. Thicker options would compromise fit, while lighter densities would bottom out too quickly. This research explains why spacer fabric specifications for footwear applications require precise engineering rather than maximum cushioning.

How does backpack backing require different thickness considerations?

Backpack backs need significant thickness (6-10mm) to create air channels that facilitate ventilation between the pack and the wearer's back. The thicker construction allows for strategic channel designs that direct airflow while providing adequate cushioning for load transfer. Lower density (600-800 gsm) often works better here to minimize weight while maintaining ventilation space.

We helped a backpack manufacturer optimize their suspension system by implementing zoned thickness: 8mm in the lumbar region for ventilation, 6mm across the shoulder blades for mobility, and 10mm in the hip belt for load distribution. The result was a 25% improvement in ventilation efficiency without increasing weight. This approach demonstrates why zoned spacer fabric applications in backpacks deliver better performance than uniform thickness.

How does moisture management differ between applications?

Moisture management represents perhaps the most critical difference between footwear and backpack spacer fabric requirements. Footwear linings must handle liquid sweat and external moisture with rapid transport away from the skin. Backpack backs primarily manage vapor transmission and occasional liquid sweat, requiring different moisture handling characteristics.

The 3D structure itself facilitates moisture movement, but the specific fiber content and surface treatments determine how effectively each application manages its unique moisture challenges. Understanding these differences prevents the common mistake of selecting spacer fabric based on cushioning alone while neglecting critical moisture performance.

What moisture properties are critical for footwear linings?

Footwear linings require excellent liquid transport to move sweat away from the skin quickly, preventing blister-causing moisture buildup. Hydrophilic coatings or moisture-wicking fiber treatments enhance this natural transport. The fabric must also resist odor buildup and maintain quick-drying characteristics even when compressed.

We developed a specialized spacer fabric for a running shoe company that incorporated antimicrobial treatment and enhanced wicking properties. The result was a 40% reduction in moisture-related discomfort reports from their wear testers. Runners noted their feet felt drier during long training sessions, particularly in humid conditions. This improvement shows why moisture management in footwear spacer fabrics requires specific engineering beyond basic 3D structure.

How do backpack backs handle vapor versus liquid moisture?

Backpack spacer fabrics primarily manage moisture vapor from perspiration rather than liquid sweat. The thicker construction creates air channels that facilitate vapor dispersion while the fabric itself may incorporate moisture-wicking properties to handle occasional liquid moisture. The key is maintaining ventilation space even during compression from pack load.

Our testing with backpackers carrying 30-pound loads showed that 8mm spacer fabric maintained 70% of its ventilation capacity under load, while 6mm fabric dropped to 50%. This difference translated to significantly better comfort during extended carries in warm conditions. Understanding vapor management in backpack spacer systems helps manufacturers optimize thickness for their specific load ranges.

What durability factors vary between applications?

Durability requirements differ significantly between footwear and backpack applications due to their distinct wear patterns and stress types. Footwear spacer fabrics face constant abrasion, compression, and flexing, while backpack backs experience sustained compression with occasional abrasion from pack contents and external objects.

The connecting threads between the two fabric surfaces determine much of the durability characteristics. Thicker, more numerous connecting threads provide better compression recovery but may reduce breathability. The balance must match the specific application's stress profile and expected lifespan requirements.

Why does compression recovery matter more in footwear?

Footwear spacer fabrics experience dynamic compression with every step—approximately 1,500-2,000 compressions per mile walked. This constant cycling requires excellent recovery to maintain cushioning and prevent "bottoming out." The connecting thread density and material composition significantly impact long-term compression recovery.

We tracked hiking boots using different spacer fabrics and found that materials with 85%+ recovery after 100,000 cycles maintained comfort through 500+ miles of use. Fabrics dropping below 70% recovery showed noticeable comfort degradation around the 200-mile mark. This data demonstrates why compression recovery in footwear spacer fabrics directly correlates with product lifespan.

How does abrasion resistance differ between applications?

Footwear spacer fabrics face internal abrasion from sock friction and foot movement, requiring smooth face fabrics and robust connecting threads. Backpack spacer fabrics experience external abrasion from pack contents and occasional contact with rough surfaces, needing tougher outer layers while maintaining internal comfort.

We helped a backpack company solve a durability issue by implementing a hybrid approach: standard spacer fabric for most contact areas with reinforced, higher-denier face fabric in high-wear zones. This targeted approach extended product lifespan by 40% without compromising overall comfort. This solution shows why application-specific abrasion resistance requires understanding wear patterns.

How do manufacturing considerations affect selection?

Manufacturing processes significantly influence spacer fabric performance and applicability. Knitting techniques determine the pattern and density of connecting threads, while finishing treatments affect surface characteristics and durability. Understanding these manufacturing variables helps select fabrics that work within production constraints while delivering required performance.

Footwear manufacturing often requires finer cutting and sewing tolerance, favoring spacer fabrics with good dimensional stability and edge integrity. Backpack manufacturing can accommodate thicker materials but demands consistent quality across larger fabric areas. The selection must consider both end-use performance and manufacturing feasibility.

Why does dimensional stability matter in footwear production?

Footwear components undergo precise cutting and assembly where even minor fabric distortion can cause fit issues or production rejects. Spacer fabrics with good dimensional stability maintain their shape during cutting, sewing, and lasting processes, ensuring consistent final products.

We implemented a quality control protocol for a shoe manufacturer that reduced spacer fabric-related rejects by 60%. The protocol included measuring dimensional stability under tension and during adhesive application—two common stress points in footwear production. This attention to manufacturing realities demonstrates why spacer fabric stability in footwear production affects both quality and efficiency.

How do backpack manufacturing processes influence fabric selection?

Backpack manufacturing involves larger pattern pieces and different stress points than footwear production. Spacer fabrics for backpacks need consistent performance across wider areas and must withstand different sewing and attachment methods. The fabric's behavior during cutting and assembly directly impacts production efficiency and final product quality.

We developed a specialized spacer fabric for a backpack brand that incorporated slightly stiffer connecting threads to prevent shifting during large-panel cutting. The change reduced material waste by 15% and improved pattern alignment in finished products. This manufacturing-focused improvement shows why production-friendly spacer fabric characteristics benefit both manufacturers and end users.

Conclusion

Selecting spacer fabric for footwear versus backpack applications requires understanding their fundamentally different performance requirements. Footwear demands thinner, denser constructions with excellent compression recovery and precise fit characteristics. Backpack backs need thicker, more open structures optimized for ventilation and load distribution. The optimal choice balances cushioning, moisture management, durability, and manufacturing considerations specific to each application.

Remember that the most expensive or technically advanced spacer fabric may not deliver the best performance if mismatched to the application. Successful selection comes from testing complete products under real-use conditions and understanding how the spacer fabric interacts with other materials in the final construction.

If you're developing footwear or backpack products and need guidance on spacer fabric selection, contact our Business Director Elaine at elaine@fumaoclothing.com. We'll help you navigate the complex performance trade-offs to select the optimal spacer fabric for your specific application, ensuring your products deliver comfort and durability that meets customer expectations.