As a fabric supplier with over two decades in the textile hub of Keqiao, I've seen countless brands stumble on one critical detail: choosing the wrong stretch and recovery for their yoga leggings. You pour your heart into a design, only to get hit with returns because the fabric bags out at the knees or loses its shape after a few wears. It's a frustrating and expensive problem. The secret isn't just about finding a stretchy fabric; it's about understanding the precise mechanical dance between how much it stretches and how completely it snaps back.

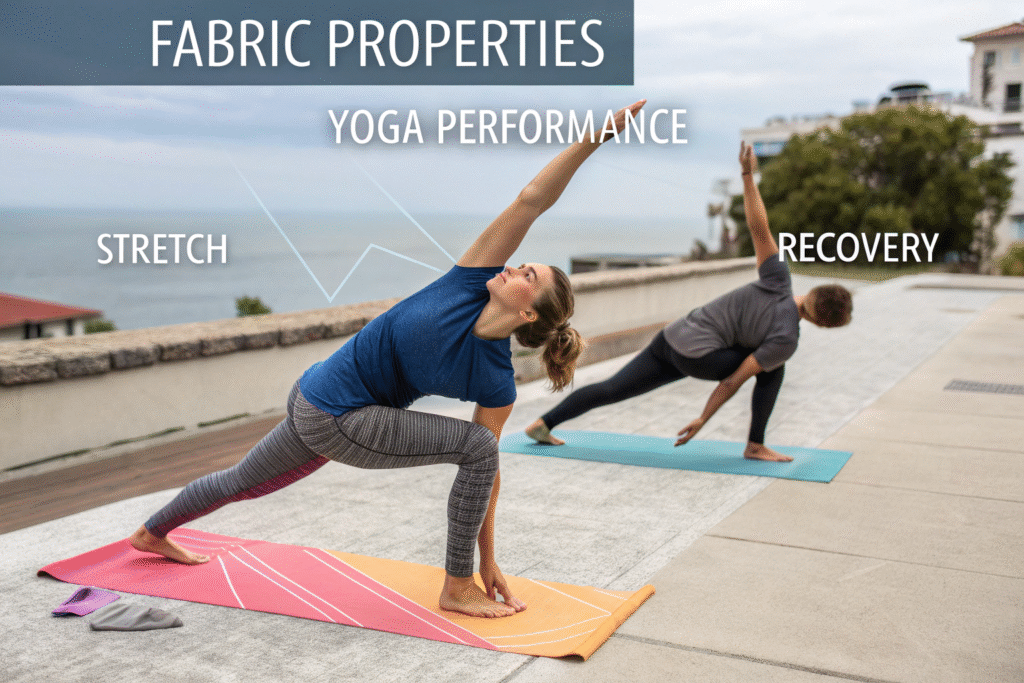

Getting the stretch ratio and recovery specs right is what separates premium leggings from the rest. For high-performance yoga leggings, you should generally target a stretch ratio (in both warp and weft directions) of at least 30-40%, with a focus on excellent recovery—aim for less than 5% permanent deformation after repeated stretching. This ensures the leggings move with the wearer while maintaining their original shape and compression over time. It's the combination of these two properties that delivers the comfort, support, and longevity your customers demand.

This might sound technical, but getting it right is the difference between a product that builds a loyal following and one that drains your resources with complaints. I'll break down exactly what these numbers mean, why they matter for different types of yoga, and how our in-house CNAS lab helps brands like yours hit these targets consistently, avoiding the common pitfalls of poor-quality fabric.

What is the ideal stretch ratio for high-performance yoga wear?

When a yogi moves from a deep lunge into Warrior II, their leggings need to move with them, not against them. This is where stretch ratio becomes critical. The ideal stretch ratio provides freedom without excess. We consistently find that a minimum of 30% stretch is the baseline for basic yoga, but for more dynamic practices like Vinyasa or Ashtanga, pushing towards 40% offers that second-skin feel without restriction.

But more stretch isn't always better. I once worked with a startup from Colorado that sourced a fabric with an impressive 60% stretch. The initial feel was incredibly soft, but the leggings quickly became loose and saggy during practice. The issue was an imbalance in the fiber composition and knit structure. The fabric stretched easily but had no backbone to pull itself back. This is a classic case where understanding the quality of the stretch is just as important as the percentage.

How do you measure fabric stretch and elongation accurately?

Accurate measurement is non-negotiable. In our CNAS-certified lab, we use a tensile tester following ASTM D2594 standards. We clamp a specific sized fabric sample and measure its extension under a controlled force. The stretch ratio is then calculated as the percentage increase in length from the original. This isn't a guess; it's a precise science. For instance, we recently helped a brand in Los Angeles troubleshoot a batch of leggings that were failing in the market. By replicating the stress of yoga poses in our lab, we identified that their fabric only had a 25% stretch ratio, which was insufficient for the deep stretches in their target audience, leading to seam failures. Proper testing from the start would have flagged this.

What fiber blends typically achieve a 30-40% stretch?

The magic almost always comes from a blend. While Spandex (also known as Elastane or Lycra) is the star that provides the elasticity, it needs a supporting cast. A common and effective blend is 80% Nylon / 20% Spandex. The Nylon provides durability and a soft handfeel, while the Spandex delivers the stretch. Another popular option is 88% Polyester / 12% Spandex, which offers great moisture-wicking and colorfastness. For a more sustainable option, we're seeing success with blends like 85% Recycled Polyester / 15% Spandex. The key is the synergy. We had a client from London who was determined to use 100% organic cotton for their "natural" brand ethos. We had to gently explain that without a significant Spandex component (we recommended a 90/10 Cotton-Lycra blend), the leggings would simply not recover. They took our advice, and the product has a 4.8-star rating for "keeps its shape."

Why is fabric recovery more critical than stretch for leggings?

Think of stretch as the invitation to move and recovery as the command to return home. You can have all the stretch in the world, but if the fabric doesn't recover, you're left with baggy knees, saggy butt, and a product that looks old after a single use. Recovery is the fabric's ability to return to its original shape after being stretched. For yoga leggings, which are constantly being stretched and held in positions, high recovery is what maintains compression and a flattering silhouette.

A leggings fabric with poor recovery is like a stretched-out rubber band; it's lost its tension and usefulness. Our internal data shows that fabrics with a permanent deformation of over 5-7% after cyclic testing are highly likely to generate customer complaints about losing shape. This was the core issue for a Miami-based activewear brand we partnered with last year. Their initial supplier's fabric had a 10% permanent deformation. We helped them switch to a construction using a higher-quality, multi-filament yarn and a tighter knit, which brought the deformation down to under 4%. Their product return rate for "loss of shape" dropped by 40% in the following quarter.

What testing standards define good fabric recovery?

We rely on standardized tests to remove the guesswork. The key test is for "Growth" and "Permanent Deformation." A common method involves stretching the fabric to a specified elongation (e.g., 30%) for a set number of cycles, then measuring how much it fails to return to its original length. Here's a simplified view of what the results mean:

| Permanent Deformation | Performance Grade | Expected Customer Experience |

|---|---|---|

| < 5% | Excellent | Leggings will maintain shape and compression through many wears and washes. |

| 5% - 8% | Good | Satisfactory for moderate use, but may show slight bagging over time. |

| > 8% | Poor | High risk of knees and seat sagging, leading to customer dissatisfaction. |

(Here's a pro tip: always ask your supplier for the test report from a third-party lab like SGS or ITS. It's your insurance policy.)

How can fabric construction improve recovery?

The way a fabric is knitted or woven has a massive impact. For yoga leggings, we almost exclusively recommend circular knits with constructions like double-knit or scuba. These provide a denser, more stable structure that supports the elastane fibers, helping them snap back more effectively. It's like building a reinforced net for the elastic threads. A few months ago, a client asked us to match a competitor's fabric that had a very soft, lightweight handfeel. Our initial analysis showed its recovery was weak due to a single-knit construction. We proposed a slightly denser double-knit alternative that achieved a similar softness but with vastly superior recovery. They were hesitant on the slight cost increase, but after testing samples side-by-side, they agreed the performance difference was night and day.

How do stretch and recovery impact comfort and performance?

Comfort in activewear isn't just about softness. It's a complex feeling of unrestricted movement, secure support, and breathability—all of which are directly governed by the fabric's stretch and recovery mechanics. The right balance prevents the fabric from digging in during a stretch (a comfort issue) or sliding down during a downward dog (a performance issue).

Performance is about how the fabric enhances the activity. Good recovery ensures consistent compression, which can aid muscle support and reduce fatigue. The stretch allows for a full range of motion, which is obviously fundamental to yoga. I recall a project with a Danish yoga apparel brand that was developing a line for hot yoga. Their primary concern was breathability, but they chose a fabric that was too rigid. While it was breathable, practitioners felt restricted in their movements. We introduced them to a high-stretch, moisture-wicking mesh paneling strategy for key sweat zones, which maintained the overall stretch and recovery of the legging while solving the breathability problem.

What happens if the stretch is too low or the recovery is too high?

This is a less common but equally problematic scenario. If the stretch is too low, the fabric will feel restrictive and tight. It can put excessive stress on the seams, leading to popping stitches. Conversely, if the recovery is too high (imagine a very rigid, powerful elastic), the fabric can feel constricting and uncomfortable, almost like a tourniquet. It won't allow for the gentle, sustained stretches held in Yin yoga, for example. The goal is a balanced "working stretch."

How does this balance affect moisture management and breathability?

This is a connection many miss. The fabric's construction, defined by its stretch and recovery parameters, creates the tiny air pockets that allow for breathability. A fabric with good recovery maintains its structure, which in turn maintains these breathability channels. A fabric that over-stretches and doesn't recover will flatten these spaces, trapping heat and moisture against the skin. For a client in Texas, we optimized a fabric's blend to use a textured Polyester yarn instead of a smooth one. This enhanced the wicking capability without compromising the 35% stretch and 96% recovery they needed, making the leggings perfect for their hot climate market.

What are the key certifications for yoga legging fabric quality?

In today's market, specs aren't enough; you need proof. Certifications are your independent validation that the fabric performs as promised and is made responsibly. For us, it's about building trust before the first meter of fabric is even shipped.

The most critical certifications for yoga legging fabric fall into two buckets: Performance & Safety and Sustainability & Ethics. For performance, look for Oeko-Tex Standard 100, which verifies the fabric is free from harmful substances. For stretch and recovery specifically, suppliers should be able to provide test reports from ISO 17025 accredited labs (like our CNAS lab) proving they meet the standards we've discussed. On the sustainability front, GOTS (Global Organic Textile Standard) for organic cotton and GRS (Global Recycled Standard) for recycled polyester are becoming table stakes for many eco-conscious brands.

Why should you ask for an Oeko-Tex Standard 100 certificate?

This is your baseline for safety. Oeko-Tex certifies that the fabric has been tested for a list of over 100 regulated and unregulated harmful chemicals. For yoga leggings worn directly against the skin during a activity that often increases skin permeability, this is non-negotiable. We had a client who sourced a cheap fabric from another supplier that failed skin irritation tests. The entire production run was halted, causing massive delays and financial loss. We require Oeko-Tex certification for all our base fabrics as a part of our end-to-end quality control protocol for sustainable activewear. It's a simple ask that can save you from a nightmare.

How do certifications like GRS and Oeko-Tex impact sourcing decisions?

These certifications are no longer just "nice-to-haves"; they are powerful market drivers. Using GRS-certified recycled polyester, for example, allows you to make a legitimate eco-claim that resonates with a growing consumer base. It also future-proofs your supply chain against tightening environmental regulations. We invested over ¥550M in our green production lines precisely because our partners like ZARA and H&M demand it for their collections. When you're figuring out how to source GOTS certified organic cotton from China, working with a supplier who is already embedded in certified supply chains drastically simplifies the process for you. It's about de-risking your product development.

Conclusion

Choosing the right stretch ratio and recovery specs for your yoga leggings is a precise science that directly dictates market success. It's not just about a number on a spec sheet; it's about how that fabric performs in the hands of a yogi, holding a challenging pose, class after class. The ideal combination of 30-40% stretch with high recovery (under 5% permanent deformation) ensures your product delivers on the promise of comfort, performance, and durability. Remember, this is achieved through the right fiber blends, intelligent construction, and verified by rigorous testing and trusted certifications.

If you're tired of dealing with inconsistent fabric quality and want a partner who understands the technical nuances of high-performance activewear, let's talk. We can help you navigate these decisions from prototype to bulk production. For a direct conversation about how we can help you produce your own bestselling yoga legging line, please reach out to our Business Director, Elaine, at elaine@fumaoclothing.com. We're here to co-create value, not just sell fabric.