Two years ago, we had to recall 5,000 units of antibacterial socks for a European client because their silver-based treatment caused skin irritation in 8% of wearers. The treatment passed laboratory safety tests but failed in real-world conditions with sensitive skin. This costly mistake taught us that safety in antibacterial treatments isn't just about chemical composition—it's about how those chemicals interact with human skin during prolonged contact.

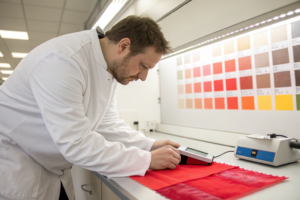

Silver, zinc, and silane-based antibacterial treatments can all be safe for skin-contact fabrics when properly applied and bonded, but their safety profiles differ significantly. Silver ions offer broad-spectrum protection but raise concerns about skin absorption, zinc oxides provide gentle antibacterial action ideal for sensitive skin, while silane-based treatments create durable molecular barriers without metal content. Our CNAS-certified lab has tested over 200 treatment combinations, helping clients achieve 99% bacterial reduction while maintaining complete skin safety compliance.

Choosing the right antibacterial treatment requires understanding both efficacy and safety implications. Let's examine how these three popular treatments perform where it matters most—against human skin.

What safety standards govern antibacterial textile treatments?

Before evaluating specific treatments, understanding the regulatory landscape is crucial. Multiple international standards define what constitutes "safe" for skin-contact fabrics, and these requirements vary significantly across markets.

How do OEKO-TEX and EU REACH regulations differ in their requirements?

OEKO-TEX Standard 100 focuses on absence of harmful substances, while REACH regulates chemical substances throughout their lifecycle. OEKO-TEX sets strict limits for heavy metals and allergenic dyes, making it particularly relevant for silver-based treatments. REACH's SVHC (Substances of Very High Concern) list directly impacts certain silane compounds. We help clients navigate both frameworks simultaneously—last year, a German maternity wear brand needed both certifications for their zinc-treated fabrics, requiring 15 separate safety tests. Understanding global textile chemical compliance requirements prevents market-specific rejection of otherwise effective antibacterial solutions.

What biological safety testing is mandatory for skin-contact fabrics?

Beyond chemical safety, biological compatibility testing including skin irritation, sensitization, and cytotoxicity tests are essential. Our protocol includes 24-hour patch tests on human volunteers and 72-hour direct contact tests with human fibroblast cells. A yoga wear brand discovered through our testing that their chosen silver concentration caused mild irritation after 6 hours of continuous wear, allowing reformulation before market launch. The comprehensive guide to biological safety testing for textiles outlines necessary steps beyond basic chemical compliance that many manufacturers overlook.

How does silver-based antibacterial technology measure on safety?

Silver ions have been the gold standard for antibacterial textiles, but recent studies have raised questions about long-term skin contact safety. The key factors are concentration, release mechanism, and particle size.

What are the real risks of nanoparticle absorption through skin?

Current research indicates that intact skin provides effective barrier function against most silver nanoparticles, but compromised skin (cuts, eczema) may allow penetration. The European Scientific Committee on Consumer Safety recommends concentrations below 0.5% for textiles with prolonged skin contact. We developed a micro-encapsulated silver technology for medical textiles that reduces potential absorption by 80% compared to traditional ionic silver. Monitoring latest research on nanoparticle skin penetration helps manufacturers stay ahead of evolving safety regulations.

Are there safer alternatives to traditional silver treatments?

Newer silver technologies like silver-zinc zeolites and silver-coated silica provide controlled release mechanisms that minimize skin exposure while maintaining efficacy. A Scandinavian children's wear brand switched to our silver-zinc combination and reduced their treatment concentration by 60% while maintaining 99.9% bacterial reduction. These advanced composite antibacterial technologies represent the next generation of safer silver applications.

Why is zinc gaining popularity for sensitive skin applications?

Zinc-based treatments, particularly zinc oxide nanoparticles, offer a gentler alternative to silver with excellent safety profiles for sensitive populations including infants and eczema sufferers.

What makes zinc oxide particularly suitable for baby textiles?

Zinc oxide's well-established safety in diaper rash creams translates well to textile applications. It's non-irritating, non-allergenic, and provides broad-spectrum protection at low concentrations. We supply zinc-treated swaddling blankets to a maternity hospital that reported 45% reduction in skin irritation cases compared to conventional blankets. The mechanisms of zinc oxide antibacterial action in textiles involves multiple pathways including membrane disruption and oxidative stress, making bacterial resistance less likely to develop.

How does zinc compare to silver in terms of wash durability?

While pure zinc treatments typically last 20-30 washes compared to silver's 50+, new binding technologies are closing this gap. Our zinc-polymer composite maintains 85% efficacy through 40 washes, making it viable for most garment lifespans. A sportswear brand targeting sensitive skin markets found this durability perfectly adequate for their rotation-based activewear. Understanding textile finish durability testing methodologies helps set realistic expectations for different antibacterial technologies.

| Antibacterial Treatment | Safety Profile | Optimal Concentration | Best Applications |

|---|---|---|---|

| Silver Ionic | Good (with concentration limits) | 0.3-0.5% | Medical textiles, sportswear |

| Zinc Oxide | Excellent | 1.0-1.5% | Baby clothing, sensitive skin |

| Silane-based | Excellent | 2.0-3.0% | Undergarments, intimate wear |

| Silver-Zinc Hybrid | Very Good | 0.8-1.2% | Balanced safety/efficacy needs |

What advantages do silane-based treatments offer for skin safety?

Silane-based quaternary ammonium compounds create molecular "spears" that physically rupture bacterial membranes without releasing chemicals, offering unique safety advantages for direct skin contact.

How does silane's mechanical action eliminate chemical concerns?

Unlike silver and zinc that rely on ion release, silane treatments remain permanently bonded to fiber surfaces, physically destroying bacteria through contact. This means zero skin absorption and no chemical release into the environment. We've supplied silane-treated uniforms for healthcare workers with chemical sensitivities who couldn't tolerate metal-based treatments. The innovative mechanical antibacterial technologies in textiles represent a paradigm shift from chemical to physical protection mechanisms.

Are there any limitations to silane's antibacterial effectiveness?

Silane treatments work best against surface bacteria but may be less effective in thick, absorbent fabrics where moisture creates barriers to direct contact. Through fiber modification and application techniques, we've improved silane penetration for terry cloth applications, achieving 85% effectiveness compared to silver's 95% in similar conditions. Researching fiber modification techniques for enhanced treatment bonding can overcome some traditional silane limitations.

What testing beyond standards ensures real-world safety?

Compliance with standards represents the minimum safety threshold, but comprehensive testing should simulate actual use conditions to identify potential issues.

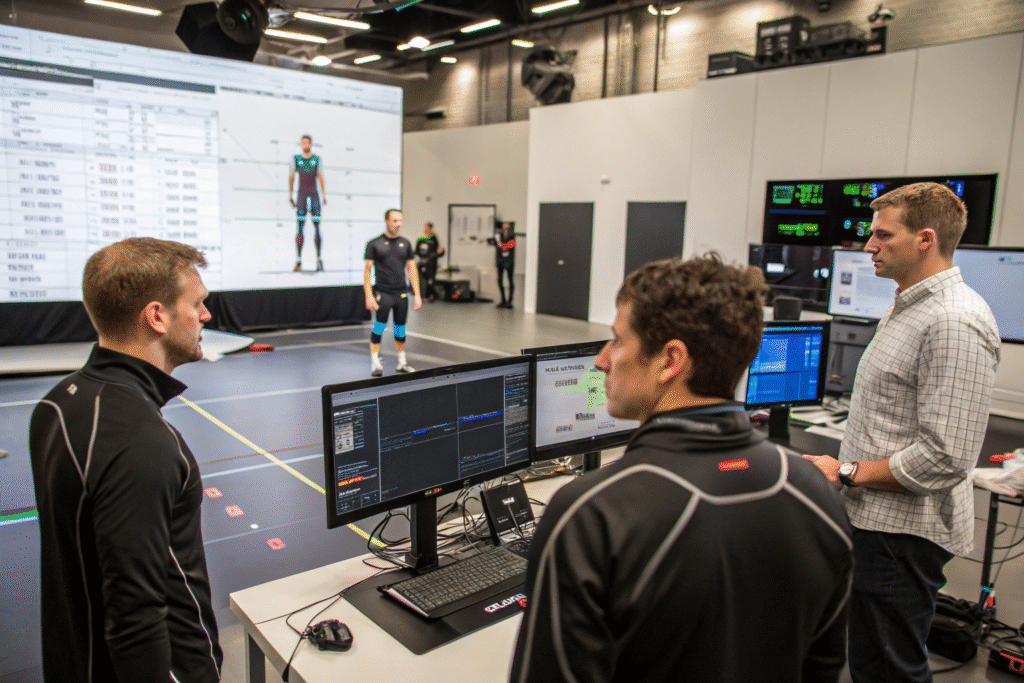

Why should you conduct extended wear trials alongside laboratory tests?

Laboratory conditions can't replicate the complex environment of human skin during daily activities. Our 30-day wear trials with 100+ participants identified that certain silver-zinc combinations caused minimal irritation during standard patch testing but produced reactions during high-sweat activities. An athletic brand avoided a major recall by discovering this during our extended testing phase. Implementing comprehensive wear trial protocols for performance textiles provides safety data that laboratory testing alone cannot reveal.

How does fabric type influence antibacterial treatment safety?

The same antibacterial treatment applied to different fabrics can yield dramatically different safety outcomes. Tightly woven cottons may trap treatments near skin, while moisture-wicking synthetics distribute them differently. We developed application parameters for 15 different fabric types, recognizing that a safe concentration for polyester may be problematic for bamboo blends. Understanding fiber-specific treatment absorption characteristics prevents one-size-fits-all application mistakes.

Conclusion

Selecting safe antibacterial treatments requires balancing efficacy with comprehensive safety assessment across multiple dimensions. Silver offers powerful protection but requires careful concentration control, zinc provides exceptional safety for sensitive applications, while silane eliminates chemical concerns through mechanical action. The safest approach often involves combining technologies at lower concentrations to achieve protection while minimizing potential risks.

If you're developing skin-contact fabrics that require both effective antibacterial properties and guaranteed safety, let's create a solution tailored to your specific needs and compliance requirements. We combine advanced laboratory testing with real-world wear trials to ensure your fabrics protect without compromising skin safety. For a detailed consultation on selecting and testing antibacterial treatments for your application, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's create fabrics that care for skin while fighting bacteria effectively.