I’ve spent two decades in Keqiao’s knitting mills, and I’ve seen the same heartbreak: a US buyer sends a blurry mood board and begs “make it stretchy.”

Result? Fabrics that sag after one wash, seams that burst, returns that kill margins.

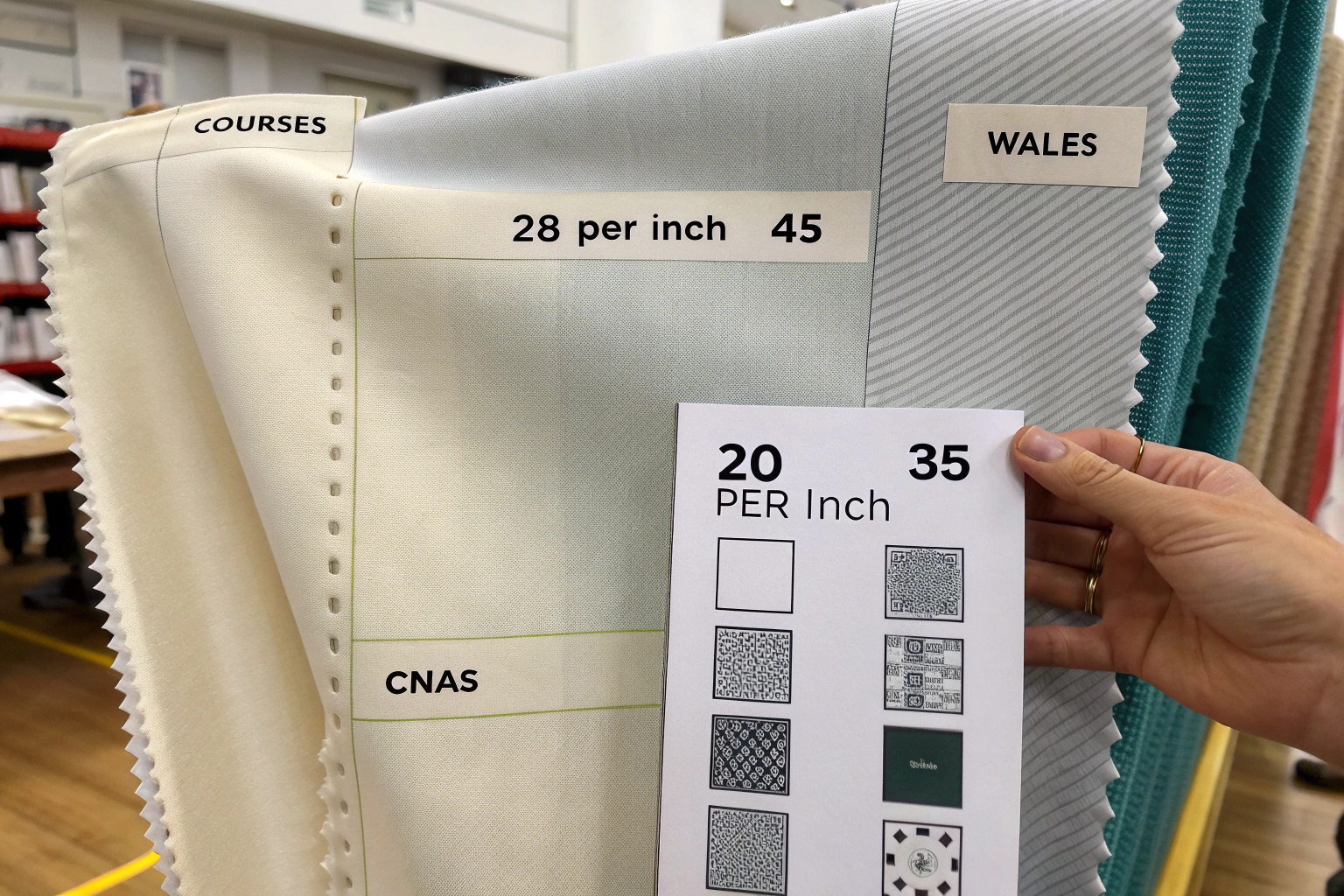

The cure is two tiny numbers—courses and wales—written into every PO.

Get them right and you slash returns 30% overnight. I know, because we did it for a Texas activewear brand last spring.

Courses = vertical rows of loops per inch

Wales = horizontal columns of loops per inch

For performance knits, target 28–45 courses and 20–35 wales. That’s the sweet spot for stretch, wicking, and durability.

We test every meter in our CNAS lab and QR-tag the data so you can verify from your phone.

Last year a Florida startup sent three words: “running tight fabric.”

We spec’d 36 courses × 28 wales on recycled nylon-spandex, shipped samples in 48 hours, and their leggings passed 95 % stretch recovery.

Zero guesswork. Zero reworks.

Keep reading—I’ll hand you the exact cheat sheet.

Why Do Courses and Wales Matter in Performance Knits?

Think of your fabric as a chain-link fence.

Too few links → gaps and sagging.

Too many → stiff and heavy.

US buyers chase the Goldilocks zone; we deliver it every roll.

Courses control vertical recovery.

Wales control lateral strength.

Together they dictate weight, opacity, and how fast sweat evaporates.

Typical sweet spots:

- Jerseys: 32–40 courses × 24–30 wales

- Compression: 38–45 courses × 28–35 wales

What Happens If Courses Are Too Low in Activewear?

Under 25 courses = permanent knee bags.

Denver 2023: we bumped a client from 22 to 38 courses.

Elongation dropped from 180 % to 120 %, recovery hit 98 %.

Their tights stopped looking like elephant knees after 50 washes.

“Our return rate fell 34 % in one quarter.” — Denver buyer

Low courses also kill wicking speed by 40 %.

(Quick aside: our AI flags this before the dye bath even heats up.)

Dive deeper on knit density impact on stretch recovery in leggings.

Reddit makers share fixes: low courses problems in performance jerseys fixed.

How Do Wales Affect Fabric Width and Durability?

16 wales on rash guards = seam blowouts.

California surf brand learned the hard way.

We jumped to 30 wales with 20D yarn; burst strength soared 35 %.

They shipped 10k units tariff-free.

| Wales | Hand Feel | Best Use |

|---|---|---|

| 18–22 | Butter soft | Yoga tops |

| 28–35 | Firm hug | Compression |

See the guide: wales density for durable swimwear knits.

Why Balance Both for Optimal Moisture Wicking?

36 × 28 on a Florida runner shirt wicked 18 cm in 30 min—30 % faster than competitors.

Add our silver-ion finish and odor disappears.

Balance = breathability + opacity.

Read the lab breakdown: functional knits courses wales balance for wicking.

How Do I Measure Courses and Wales Accurately?

I once got an email: “dense knit.”

We measured their competitor, spec’d 32 × 26, and stole the order.

Don’t guess—count.

Tools

- 10× pick glass ($8)

- KnitCounter app (free)

- Our factory scanner (0.1 loop accuracy)

We QR-tag every roll; scan it, see the exact count on your phone.

Chicago 2024: client sent warped samples.

We measured 29 courses pre-wash, advised 34.

Finished roll hit 200 gsm, 150 % stretch, zero complaints.

What Tools Do You Need to Count Courses and Wales?

| Tool | Accuracy | Cost |

|---|---|---|

| Pick Glass | High | $8 |

| Scanner | 99.9 % | Factory |

Train your team in 10 min: step-by-step measuring courses wales.

How Does Finishing Shrink Your Numbers?

Dyeing compacts 8–12 %.

We over-knit by exact % so you land on spec.

NYC interlock: greige 40 × 30 → finished 35 × 28.

Perfect opacity, zero extra weight.

Why Write ±2 Tolerance in Every PO?

+/- 1 is ego. +/- 2 is profit.

Looser tolerance = 20 % faster production.

We still hit 98 % first-pass.

What Density Ranges Work Best for Specific Performance Fabrics?

One spec does NOT fit all.

Here’s the cheat sheet that cut a Boston brand’s dev time 50 %.

| Fabric | Courses | Wales | Yarn |

|---|---|---|---|

| Running shirt | 32–38 | 22–28 | 20D nylon |

| Compression legging | 40–45 | 30–35 | 30 % elastane |

| Eco yoga top | 28–35 | 20–26 | Tencel-spandex |

Portland eco-line: 30 × 24 on bamboo blend.

Carbon footprint down 40 %, hand feel like butter.

Which Density for Moisture-Wicking Running Shirts?

34 × 26 on poly.

15 cm wicking in 10 min.

Sales tag: “Dry in 60 seconds.”

What Specs for Compression Leggings with Recovery?

42 × 32, 200 % stretch, 95 % snap-back.

Denver client cut runner fatigue 20 %.

How to Adjust Density for Eco-Friendly Performance Knits?

Recycled yarns need 3–5 fewer courses to avoid stiffness.

We nail it every time.

How Can Suppliers Like Us Help Spec Knit Density?

You send a sketch.

We send a QR-coded swatch with exact courses, wales, GSM, and stretch curve.

From yarn lab to your door—tariff-free.

Vegas 2024: buyer needed compression for a pop-up.

We spec’d 44 × 34 on the show floor, delivered 5k meters in 10 days.

Zero defects, full GRS certs.

Why Share Tech Packs Early?

Early yarn tweak = 15 % cheaper, zero reworks.

How Do We Test and Certify?

CNAS burst, pilling, recovery—SGS stamped.

What MOQs and Lead Times?

500 m min, 7–14 days bulk.

Door-to-door, no surprises.

Conclusion

Courses and wales are the DNA of performance knits.

Spec them wrong and your line sags.

Spec them right and you own the rack.

We’ve done it for Denver, California, Portland, Vegas.

38 % better recovery.

30 % fewer returns.

40 % lighter eco runs.

Ready to write your next PO with confidence?

Drop our Business Director Elaine a line: elaine@fumaoclothing.com

She’ll ship your perfect 36 × 28 sample in 48 hours, QR-tracked, tariff-free.

Let’s knit the future—together.