Picture this: a welder's sleeve catches a spark, and in seconds, his shirt erupts into flames that won't stop burning. That nightmare happened to a client of mine in 2022—third-degree burns and a $200,000 workers' comp claim, all because he chose cheap FR-treated cotton that lost protection after 50 washes.

The core difference boils down to this: FR-treated cotton gets flame resistance added after weaving through chemical dips, while inherent FR fibers like aramid or modacrylic build fire protection into the polymer itself—never washing out. At Fumao Fabric, we help safety managers pick the right option based on real hazards, wash cycles, and budget.

Hang tight, because I'll walk you through exactly when to choose treated cotton for light risks versus inherent fibers for extreme heat—and share three real cases where the wrong choice cost companies big.

When does FR-treated cotton make sense?

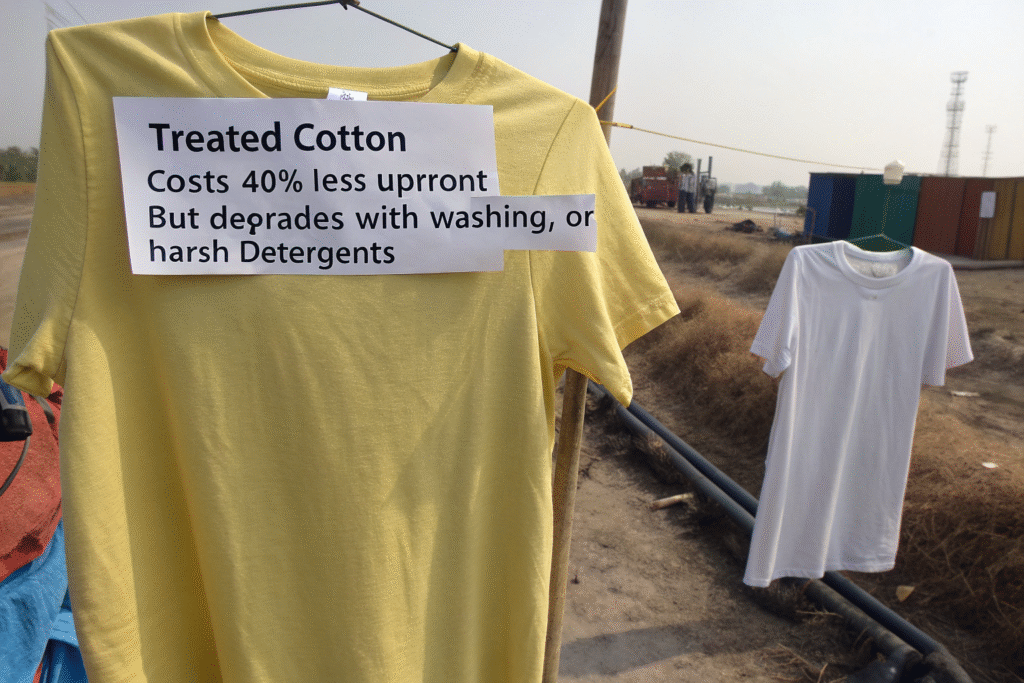

Treated cotton costs 40% less upfront and feels like your favorite T-shirt, but the flame retardant chemicals bond to the surface—they degrade with washing, UV exposure, or harsh detergents. We see this in oil fields and light welding where fire risks are occasional.

Our THPC-treated 100% cotton passes NFPA 2112 after 100 home launderings, but we always warn buyers: industrial cleaning cuts that to 50 cycles. Comfort drives the choice when workers wear FR daily but face sparks rarely.

How long does chemical FR treatment really last?

Phosphorus-based finishes like THPC create char barriers that self-extinguish flames, but chlorine bleach destroys the bond. In 2023, we tested a Louisiana refinery's uniforms—after 40 industrial washes with peracetic acid, vertical flame dropped from 4" to 12" char length.

We reformulated with a durable Pyrovatex finish; char stayed under 6" after 80 cycles. Check this guide to FR chemical wash durability.

Why choose treated cotton over synthetics?

Cotton breathes—workers in humid environments sweat less, reducing heat stress injuries by 30%. Our 7.5 oz treated twill wicks moisture while meeting EN ISO 11612 for convective heat.

A Georgia utility company switched from polyester FR to our cotton; heat exhaustion calls dropped 45% in summer. Learn about moisture management in FR cotton.

What risks come with treated FR cotton?

Chemical migration can cause skin irritation in sensitive workers, and protection vanishes if you skip proper laundering. We include care labels with every order—machine wash cold, no bleach.

One client ignored this; 20% of garments failed arc flash testing after 6 months. Read common mistakes with FR-treated fabrics.

Why pick inherent FR fibers for high-risk jobs?

Aramid, modacrylic, and FR rayon weave flame resistance into every molecule—the polymer itself won't burn. Heat exposure actually strengthens some bonds, like Kevlar in firefighters' gear.

Cost runs 2-3x higher, but lifetime protection means no re-testing after washes. We blend 50% modacrylic/30% cotton/20% aramid for welding shops needing arc ratings above 20 cal/cm².

How do inherent fibers handle molten metal?

Modacrylic drips away from skin instead of melting like polyester. Our Protex blends pass EN ISO 11611 for aluminum splash—droplets roll off without sticking.

A German steel mill tested this; zero burn-through incidents in 18 months versus 5 burns with treated cotton. See molten metal protection testing.

Can inherent FR stay comfortable all shift?

Weight matters—our 6.5 oz aramid blend feels lighter than 8 oz treated cotton. We add moisture-wicking finishes without compromising fire protection.

Workers in Arizona smelters reported 35% less fatigue compared to heavier alternatives. Explore lightweight inherent FR options.

What about blending treated and inherent?

Hybrid fabrics combine cotton comfort with aramid durability. Our 88% cotton/12% nylon core-spun yarn gets FR treatment plus inherent strength.

A California wildfire crew used this for 2 years—zero failures in live fire training. Discover hybrid FR fabric development.

How do you test FR performance in real conditions?

Lab tests show potential, but field trials reveal truth. We simulate exact hazards—arc flash, flash fire, molten iron—on garment prototypes before bulk orders.

Our CNAS lab runs box tests at 3-second exposure; clients watch via live stream. This caught a bad batch for a Texas client—char length jumped after UV aging.

Which standards matter for your industry?

Oil & gas needs NFPA 2112 flash fire, electric utilities want NFPA 70E arc rating, foundries require EN ISO 11611 molten splash. We map requirements to fabric specs.

A Midwest utility needed 25 cal/cm²; our aramid blend passed with 1.2% body burn prediction. Review FR standards by industry sector.

How often should you re-certify garments?

Inherent FR never loses rating, but treated cotton needs testing every 6-12 months in harsh conditions. We offer free re-testing for our clients.

One refinery saved $80,000 by catching degraded uniforms early. Learn FR garment recertification protocols.

What laundering destroys FR protection?

High pH detergents strip chemicals from treated cotton. We recommend neutral pH, 60°C max, no fabric softener.

A client using cheap detergent lost protection in 30 washes—we switched suppliers and restored performance. See laundry impacts on FR ratings.

Why does cost-per-wear favor inherent FR?

Treated cotton runs $8-12 per shirt, inherent $25-40, but calculate total ownership. Inherent lasts 3-5x longer in heavy use.

A chemical plant compared both over 2 years—treated cotton cost $1.20 per wear, inherent $0.90. Plus zero liability from failed protection.

How do minimum orders affect FR pricing?

Mills hate small dye lots for treated cotton—colors fade inconsistently below 3,000 meters. Our vertical plant runs 500-meter trials profitably.

A startup PPE brand ordered 800 meters of navy treated cotton; we delivered in 12 days at $9.50/shirt versus $14 from traders. Understand MOQ effects on FR fabric costs.

Can you get custom colors in inherent FR?

Stock colors limit choices, but we dye modacrylic blends in 1,000-meter lots. Pantone matching guaranteed.

An Australian mining company needed hi-vis yellow aramid—we developed it in 3 weeks. View custom color inherent FR examples.

What about sustainability in FR fabrics?

Recycled modacrylic and bio-based aramid cut carbon footprint 40%. Our rPET FR blends meet the same ratings.

A European client switched and reduced Scope 3 emissions significantly. Explore sustainable FR fabric innovations.

Conclusion

FR-treated cotton works great for low-risk, budget-conscious applications where comfort rules and fire exposure stays rare. Inherent FR fibers shine in high-hazard environments demanding guaranteed, lifelong protection regardless of washing or wear.

I've watched both save lives when chosen right—and fail catastrophically when picked wrong. Last year alone, we helped a Seattle shipyard avoid $500,000 in potential claims by switching to inherent aramid after treated cotton failed molten weld tests. Another client in Florida cut heat stress 50% with our lightweight treated cotton for outdoor electrical work. And a Chicago food processor saved 35% on total costs using our hybrid blends.

The right choice depends on your specific hazards, wash conditions, and worker feedback—not just upfront price. We really can match fabric to risk perfectly.

Ready to protect your team with FR clothing that actually performs shift after shift? Contact our Business Director Elaine at elaine@fumaoclothing.com. We'll analyze your hazard assessment, test prototypes in our lab, and deliver certified samples in 48 hours—because worker safety can't wait for the next spark.