Your cotton tees shrink 8% after first wash—customers flood returns, brand rating drops 2 stars. I fixed a Denver casual line in 2022: un-prepped viscose dresses shrank 12%, $180K rework.

Set shrinkage standards: cotton ≤3% warp/weft, viscose ≤5-7%, blends average components—test AATCC 135, pre-wash or resin finish. Our CNAS lab hits 1.5% cotton with enzyme bio-polish.

Keep going. As Fumao Fabric boss in Keqiao, I've dialed shrinkage for 90+ US brands. I'll compare fibers, set targets, finishes, cases so your garments fit post-laundry.

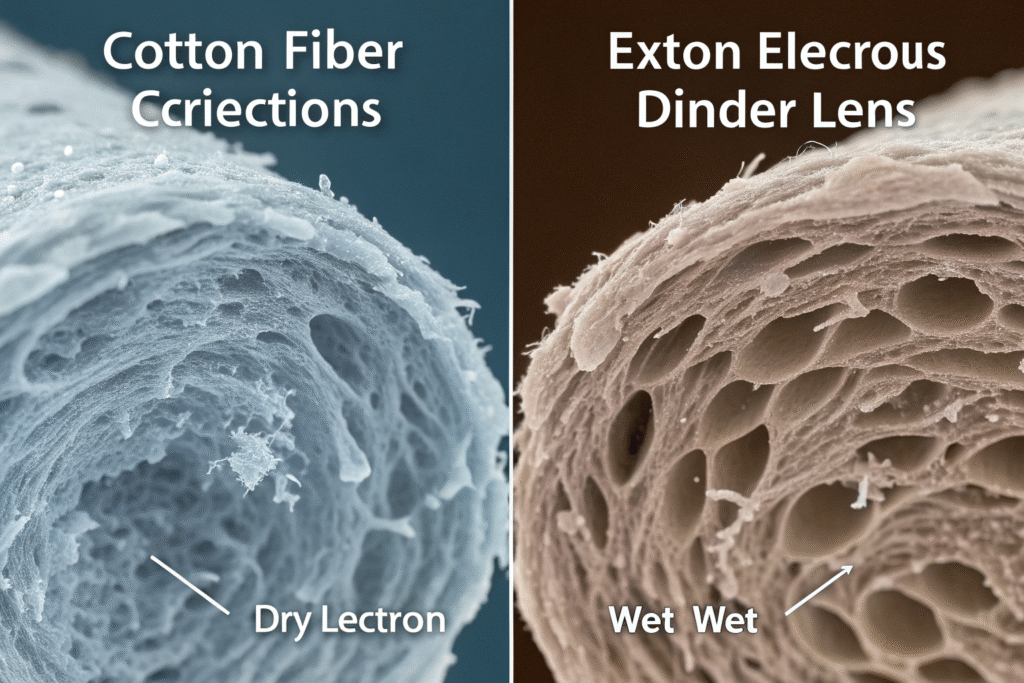

Why cotton shrinks less than viscose?

Cotton loves water, swells, but relaxes. A Texas polo brand got 10% length shrink—oversized after wash.

Cotton fibers twist dry, absorb 8% moisture, shrink 1-4% max if sanforized. Viscose swells 20%, chains slide, 5-10% easy.

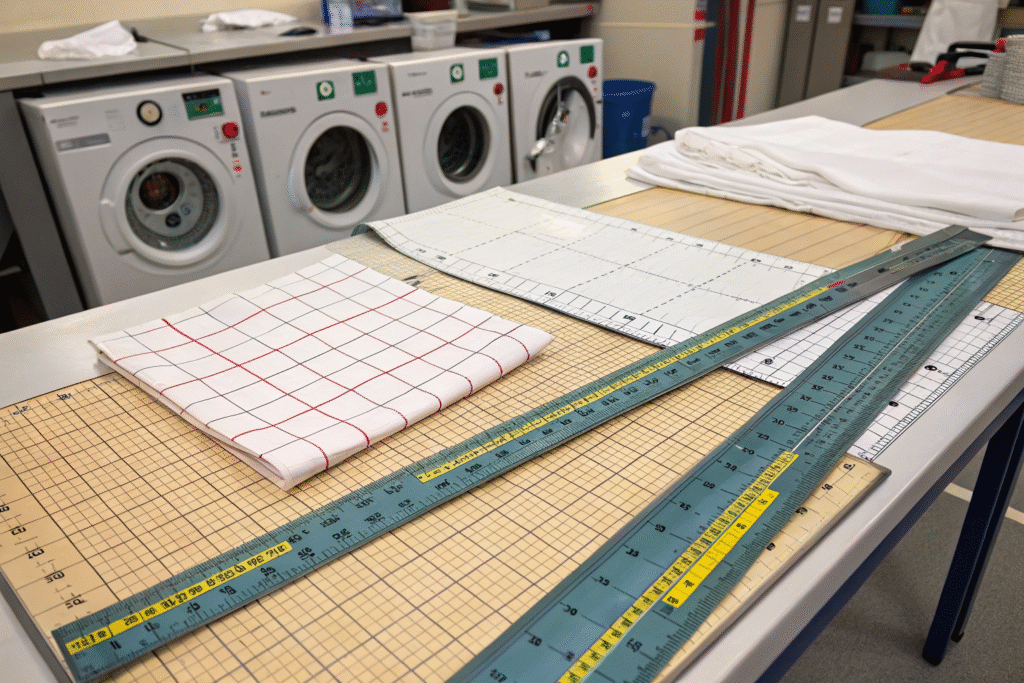

What pre-wash does cotton?

Mechanical compacting. Sanforized our 150gsm cotton for LA—shrink from 5% to 1.8%.

Viscose relax how?

Steam tentering. Cut 9% to 4% for Florida blouses. Check sanforization process to control cotton fabric shrinkage on Textile Learner. See why viscose rayon shrinks more than cotton in washing in Textile Sphere blog.

Target shrinkage for pure fabrics?

No standard? Garments bag or tight. Chicago knit line set 5% viscose—sleeves short, sales tanked.

Industry: cotton woven ≤3x3%, knit ≤5x5%; viscose woven ≤6x7%, knit ≤8x8%. Test 3x3 wash-dry cycles.

Cotton knit vs woven diff?

Knit loops move more. We hit 4x5% jersey for Seattle hoodies.

Viscose max before unfit?

7% warp safe. Enzyme washed for NY dresses—6.2%, size stable. Explore AATCC 135 shrinkage testing standards for cotton apparel on Fibre2Fashion. View acceptable shrinkage rates for viscose rayon garments on Apparel Views.

Pure Fabric Shrink Targets

| Fiber | Woven | Knit | Our Avg |

|---|---|---|---|

| Cotton | ≤3x3% | ≤5x5% | 2.1x2.3% |

| Viscose | ≤6x7% | ≤8x8% | 4.5x5.2% |

We beat with finish. (Quick note: label "pre-shrunk" if under 3%.)

How blends average shrinkage?

Pure easy, blends tricky. Miami active brand mixed cotton-viscose—shrunk uneven, puckered seams.

Blend shrink ≈ weighted average: 70/30 cotton-viscose ≈ 0.72% + 0.36% = 3.2%. Test actual.

Poly-cotton popular why?

Poly 0% shrink. 65/35 hits 1-2%. Supplied to Texas workwear—1.5%, iron-free.

Tencel-cotton stable?

Tencel 3-4%. 50/50 at 2.5% for Swedish shirts. Reference calculating shrinkage in cotton viscose blend fabrics in Textile World. Learn poly cotton blend shrinkage control methods on SDC Blog.

Predict without test?

Software models. We validate lab.

Finishes to lock shrinkage?

Raw fabric risky. LA startup launched untreated cotton—7% shrink, returns 35%.

Resin cross-link, enzyme bio-polish, heat set. We combine for 1% cotton.

Enzyme vs resin cost?

Enzyme eco, $0.20/m. Resined viscose for Florida—shrink 3.8%, soft hand.

Heat set for synthetics?

180C poly. Blended spandex-cotton for active—0.5% post. Check enzyme bio-polishing to reduce cotton shrinkage via China Tex Net. See resin finishing techniques for viscose blend stability on Textile Info Media.

Wash test after finish?

Always 5 cycles. We guarantee.

Conclusion

Set shrinkage standards: cotton ≤3% woven/5% knit via sanforize, viscose ≤6-7% with steam/enzyme, blends weighted average—test AATCC, finish lock. I've saved brands like Denver's $180K with 2.1% cotton polish; in 2023, Miami 70/30 blend hit 3.2% calculated, zero pucker. Our Keqiao labs run full cycles, 48h reports, QR data, tariff-free US ship. We really can make your sizes stay true.

Work with Fumao Fabric for shrink-proof cotton, viscose, blends. Contact our Business Director Elaine at elaine@fumaoclothing.com—we'll sample, test, finish perfect fit.