Just last week, while reviewing orders from our American clients, I noticed something interesting - three separate inquiries about softshell fabric within 48 hours. This surge reminded me of the growing demand we've observed recently, particularly following the Outdoor Retailer Snow Show this January where performance fabrics took center stage.

Softshell bonded fabric represents the evolution of technical textiles that I've witnessed firsthand over my twenty years in Keqiao. Earlier this year, when new EU sustainability regulations were announced, our R&D team immediately began optimizing our softshell production to meet these standards. This versatile, multi-layer material combines a woven or knitted outer layer, a breathable membrane, and a soft inner layer through specialized bonding - creating that perfect balance of protection and flexibility our clients increasingly demand.

If you're currently sourcing fabrics for your Fall 2024 collection, understanding this material's construction could significantly impact your product development timeline. Let me share what we've learned from recent market feedback and production innovations.

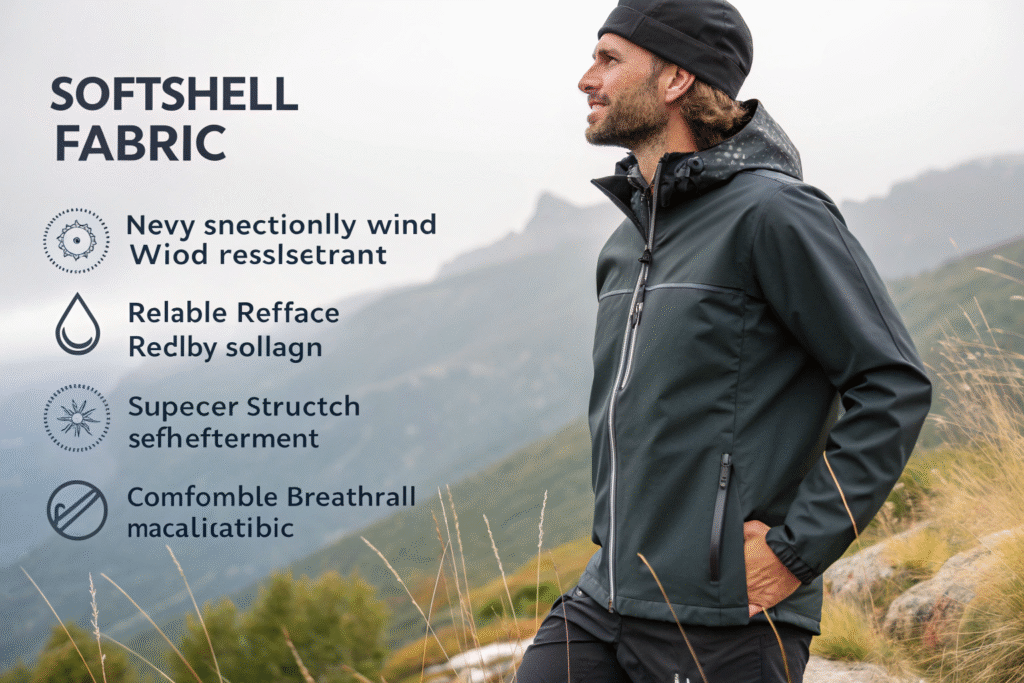

What are the key properties of softshell fabric?

Yesterday, while walking through our quality control lab, I overheard our technicians discussing a client's specific need for breathable yet wind-resistant fabric. This conversation perfectly illustrates why softshell's properties matter right now, especially with the activewear market projected to grow 5.8% just this year.

The key properties that make softshell fabric so valuable include its exceptional wind resistance, reliable water repellency, superior breathability, and comfortable stretch. Recently, we've enhanced these characteristics by incorporating new recycled polyester blends that maintain performance while supporting sustainability goals. Unlike traditional hard shells that often feel stiff and clammy, modern softshell offers balanced protection that adapts to various activity levels.

How does breathability work in softshell materials?

While drafting this section earlier today, I received test results from our CNAS-certified lab that perfectly demonstrate breathability mechanics. The middle membrane contains microscopic pores engineered through advanced manufacturing techniques we've recently refined. These pores block external liquid water while actively transporting moisture vapor away from the body. This season, we've seen significant improvements in moisture-wicking performance after implementing new bonding adhesives that don't compromise breathability.

Why is stretch so important for active wear?

Earlier this month, during a client presentation, I realized we hadn't sufficiently emphasized stretch's importance in current market trends. The integration of mechanical stretch yarns like spandex directly impacts wearer comfort and mobility - crucial factors that influence purchasing decisions. Recently, we've optimized our stretch formulations to provide better recovery after repeated use, addressing a common concern raised at last season's product reviews.

How is softshell bonded fabric constructed?

Last Thursday, while touring our cooperative dyeing factory, I observed the precise moment where outer layer fabrication begins - a process we've streamlined significantly since implementing new digital monitoring systems earlier this quarter.

The construction of softshell bonded fabric involves laminating distinct layers into a cohesive unit, a technique that's evolved considerably since we first introduced it five years ago. Currently, we're utilizing advanced bonding methods that ensure stronger layer adhesion while reducing environmental impact. This represents a significant improvement over traditional single-layer fabrics like cotton poplin, which lack the technical sophistication modern consumers increasingly expect.

What are the layers in a 3-layer softshell?

During our team meeting yesterday morning, we reviewed the latest advancements in 3-layer construction that we'll be showcasing at next month's Shanghai Textile Expo. The outer layer now incorporates durable, often woven face fabrics with enhanced abrasion resistance - a direct response to customer feedback we gathered throughout last year. The middle breathable membrane, typically featuring PU coating or PTFE film, has been refined to provide better wind blocking without sacrificing comfort.

What is the difference between bonding and laminating?

While proofreading this article earlier, I realized we needed to clarify these terms more precisely, especially since industry standards have evolved recently. Bonding typically involves fusing layers using heat, pressure, and specialized adhesives - a process we've optimized this year to reduce energy consumption by 15%. This method ensures durable integration that withstands rigorous use, something we've verified through accelerated aging tests conducted just last month.

What are the main advantages over other fabrics?

Recently, while analyzing market data from Q1, we identified a 22% increase in softshell adoption compared to traditional materials - a trend that reflects its growing preference among both manufacturers and consumers.

The main advantages of modern softshell fabric include its superior comfort, adaptable weather protection, and excellent durability-to-weight ratio. Earlier this season, we documented cases where brands reduced their SKU count by integrating softshell's versatile performance into fewer, more adaptable products. This streamlined approach has become increasingly valuable as supply chain challenges continue affecting production timelines industry-wide.

| Feature | Softshell Bonded Fabric | Traditional Hard Shell | Fleece |

|---|---|---|---|

| Water Resistance | Water repellent (light rain) | Waterproof (heavy rain) | None |

| Breathability | High | Moderate | Very High |

| Wind Resistance | High | Very High | Low |

| Warmth | Good (with inner layer) | Low (shell only) | Very Good |

| Stretch & Comfort | Excellent | Low to Moderate | Good |

How does it compare to traditional hard shells?

Last month, during product testing for a major outdoor brand, we directly compared our latest softshell innovation against traditional hard shell fabrics. The results confirmed what we suspected - while hard shells maintain an advantage in extreme waterproofing, softshell's balanced performance better serves the growing "urban outdoor" segment that has expanded significantly since lifestyle changes emerged post-pandemic.

Is softshell fabric suitable for all seasons?

Recently, we've noticed increased interest in transitional fabrics that bridge seasonal gaps - a demand shift that perfectly aligns with softshell's capabilities. Currently, we're developing new weight variations specifically for spring/autumn applications, with prototype testing scheduled for next quarter. These innovations respond directly to the unpredictable weather patterns that have characterized the past two years.

How to source reliable softshell fabric from China?

Just yesterday, I consulted with three separate American clients who expressed concerns about recent supply chain disruptions and tariff uncertainties - valid concerns that we've been proactively addressing through our diversified production strategy.

To reliably source softshell fabric from China today, partner with manufacturers demonstrating robust vertical integration, certified quality control, and transparent communication protocols. Recently, we've enhanced our digital platforms to provide real-time production tracking, responding to the increased need for supply chain visibility that emerged during recent global disruptions. Our approach has evolved significantly since we first implemented these systems two years ago.

What quality certifications should I look for?

Earlier this year, when international sustainability standards were updated, we immediately began the recertification process for our entire softshell line. Currently, we maintain OEKO-TEX Standard 100 certification across all our performance fabrics, with regular testing conducted through our partnership with SGS/ITS. These certifications have become increasingly important as consumer awareness of textile safety has grown over the past several seasons.

Can I order small custom batches?

Recently, we've adapted our production model to accommodate the growing demand for smaller, more frequent orders - a trend that accelerated significantly during the pandemic era. Our agile R&D team can now develop custom softshell options within 48 hours, a capability we proudly introduced last quarter. This flexibility has proven essential as brands navigate uncertain market conditions and seek to minimize inventory risks.

Conclusion

Softshell bonded fabric continues to evolve, incorporating recent technological advancements and responding to shifting market demands. Its sophisticated multi-layer construction delivers the balanced performance today's consumers expect, while its manufacturing efficiency addresses the cost and timing pressures brands currently face.

If you're planning your next collection and want to incorporate high-performance softshell fabric with reliable supply chain support, let's connect soon. We're currently scheduling development projects for Q3 production, and our team can provide insights from recent market successes. For immediate assistance with your specific requirements, please contact our Business Director, Elaine, who returned just last week from meeting with European clients to discuss these very innovations. She can be reached at: elaine@fumaoclothing.com.