Honestly, after twenty years in this business, I've seen more orders fail from color bleeding than almost anything else. It's heartbreaking, really—your beautiful designs arriving with colors that run at the first sign of sweat or seawater. Actually, this isn't just about quality control—it's about protecting your brand's reputation. Personally I think many importers underestimate how crucial this is until it's too late.

The real secret—and I'm being completely honest here—lies in a three-part approach: choosing the right materials from the start, testing relentlessly throughout production, and honestly, working with a supplier who gets it. Too many focus solely on price, but the true cost reveals itself later—in rejected shipments, angry customers, and frankly, damaged relationships. Getting this right from the beginning? It saves so much trouble down the line.

Let me walk you through this—not as some textbook guide, but from real experience on the factory floor. What works, what doesn't, and frankly, what most suppliers won't tell you about ensuring your fabrics can handle real-world conditions.

What even are the international test standards?

To be honest, many buyers I talk to find these standards confusing—and who can blame them? The terminology alone—AATCC, ISO—sounds like alphabet soup. But understanding them? That's your first line of defense. These standards—AATCC 15 for sweat, ISO 105-E02 for seawater—they're not just paperwork. They're proven methods that simulate exactly what your fabrics will face in the real world.

Why should you care about these standards?

Personally I think many importers make this mistake—they treat standards as bureaucratic hurdles. Actually, they're your financial protection. When you specify AATCC or ISO requirements in your contract—and you really should—you create enforceable quality benchmarks. Without them? Well, let's just say I've seen too many "he said, she said" situations that leave the buyer holding the bag—and the faulty inventory.

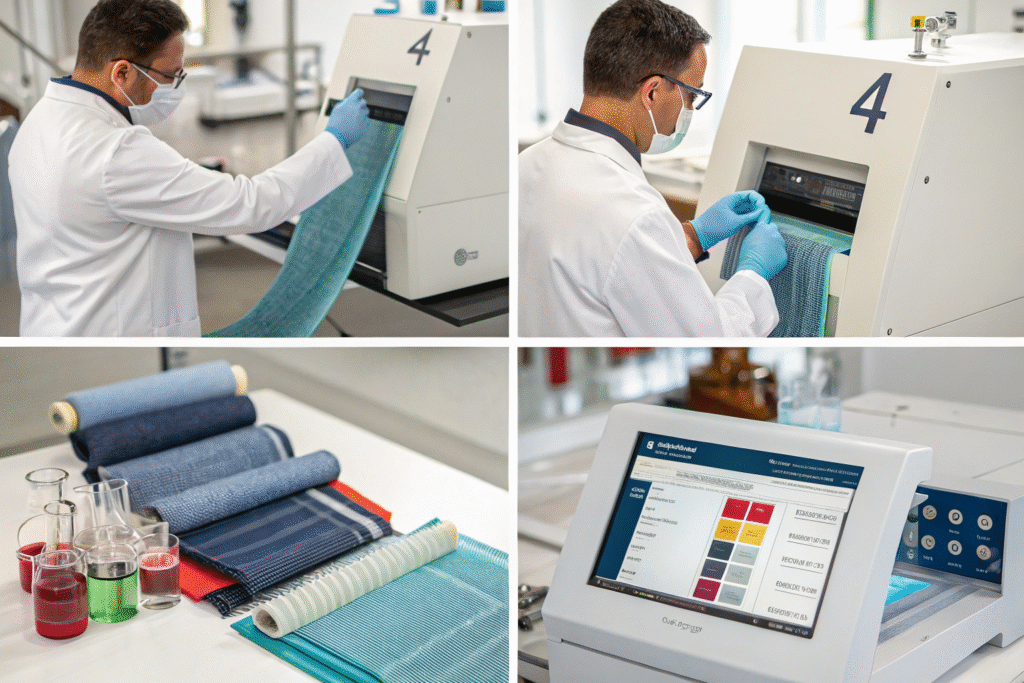

How can you check a supplier's testing capabilities?

Always ask—and I mean really ask—for their testing credentials. A good supplier, like our operation at Fumao, will have a CNAS-accredited lab right on site. Actually, you should demand to see specific test reports for fabrics similar to what you're ordering. Their willingness to provide this? It tells you everything about their transparency—and their confidence in their own quality.

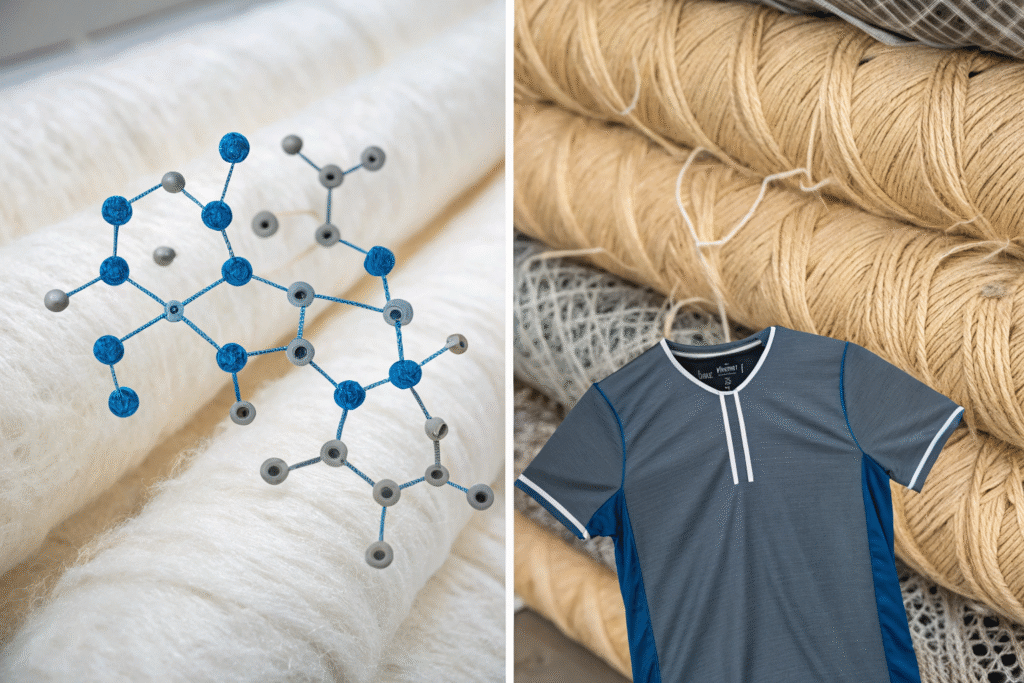

Does fiber choice really make that much difference?

Honestly, this is where many designers get tripped up—choosing fibers for aesthetics alone. The truth is, different fibers hold dye in completely different ways. Natural fibers like cotton—they breathe, they're comfortable, but they also drink up moisture, which can pull dye right out. Synthetic fibers like polyester? They can be workhorses for color retention—if processed correctly.

Are natural fibers always problematic?

Not necessarily—but they do require more expertise. Linen and hemp? Frankly, they're challenging for colorfastness. Cotton can perform well—with the right dyeing techniques and reactive dyes. Wool? Generally holds color beautifully, but sensitive to pH levels. The key isn't avoiding natural fibers—it's understanding they demand more from your dyer.

What about synthetic fibers?

Here's the thing—while polyester is famous for colorfastness, not all synthetics are created equal. Nylon, for instance, can be tricky with certain chemicals. And these new eco-friendly fabrics—Tencel, recycled polyester—they're wonderful, but they require specialized dyeing approaches. The right choice? It's always a balance—between look, performance, and frankly, what's practical for your budget.

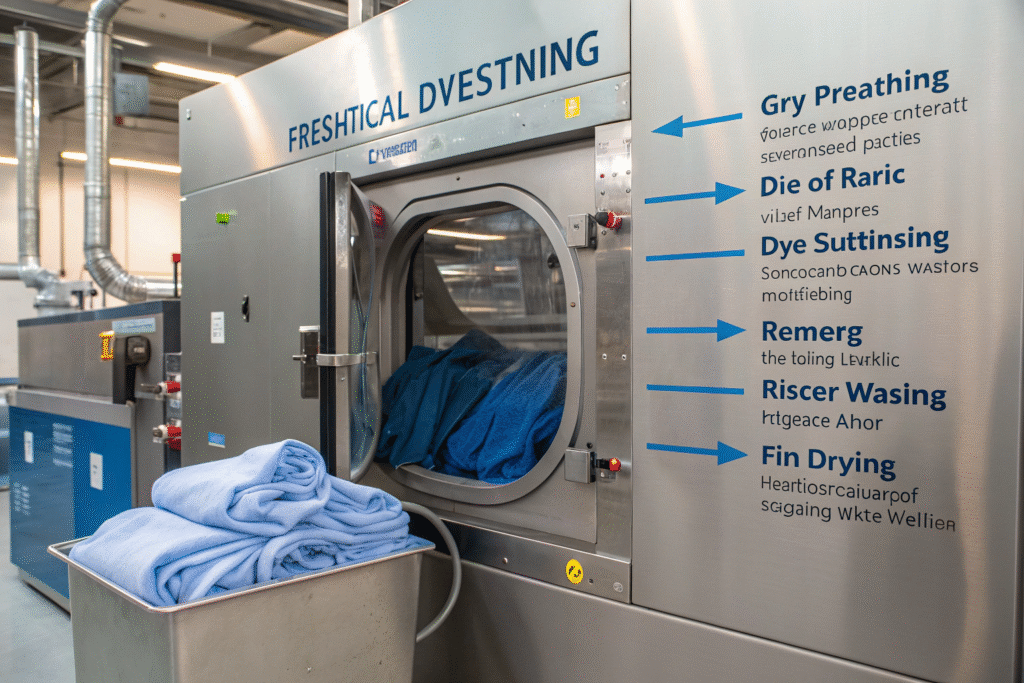

What makes some dyeing methods better than others?

The dyeing process—this is where the magic happens. Or doesn't. Simply dunking fabric in dye? That's not enough. Achieving true colorfastness requires precision—temperature control, timing, the chemical auxiliaries used. Vat dyes, reactive dyes—they cost more, but the results? Night and day difference in performance.

Why does the washing process matter so much?

This is crucial—and honestly, where many cheaper operations cut corners. After dyeing, excess dye remains on the fabric surface. If not thoroughly washed out—with multiple hot water baths—it will bleed. No question. I've seen beautiful dye jobs ruined by inadequate washing. The lesson? Proper washing isn't an optional step—it's essential.

How do functional finishes affect colorfastness?

Here's something most people don't consider—those functional finishes you want? Moisture-wicking, UV protection? They can actually interfere with dye bonds. The chemicals might create pathways for color to migrate. That's why testing should always happen after all finishes are applied—not just after dyeing. Otherwise? You're not testing the actual final product.

Is quality control really that important?

Trust but verify—that should be every importer's motto. Even with perfect materials and dyeing, without rigorous QC? You're gambling. And not just final inspection—I'm talking checkpoints at every stage. Testing after dyeing, after finishing, before shipping. The whole process.

What does proper pre-shipment inspection look like?

It should cover everything—lab tests against your specific standards, plus physical inspection. Width, weight, shrinkage—the works. And documentation? Photos, detailed reports. You should know exactly what you're getting before it ships. Actually, you deserve that visibility.

Why is on-site QC so valuable?

Lab tests take time—but having eyes on the factory floor? That gives you real-time feedback. Spotting issues early—a dye lot that looks questionable—can save weeks of production time. For an international buyer, this on-ground presence? Invaluable for managing timelines and preventing disasters.

Conclusion

Passing colorfastness tests—it's not about luck. It's about system, knowledge, and frankly, partnership. Choosing materials wisely, dyeing with expertise, and verifying quality every step of the way. Get this right, and you transform a potential headache into a competitive advantage.

Tired of color bleeding and failed inspections? Maybe it's time to work with people who live and breathe this stuff. For fabrics that actually perform—and suppliers who actually care—reach out to our Business Director, Elaine. She gets it. elaine@fumaoclothing.com. Because honestly, your fabrics should be as durable as they are beautiful.