As an experienced textile supplier, I understand the critical importance of proper fabric testing. Many brands face costly returns when their leggings lose shape or swimwear stretches out. The solution lies in comprehensive testing before production. This ensures garments maintain fit and performance through repeated use.

Accurate stretch and recovery testing separates successful activewear from failed products. Proper evaluation guarantees fabrics return to their original shape after stretching, maintaining compression and appearance over time.

Understanding these testing methods helps brands make informed sourcing decisions. Let's explore the key procedures that ensure fabric quality and durability.

Importance of Stretch Testing

Activewear demands specific performance characteristics. Stretch refers to fabric extension under tension, while recovery measures its return to original dimensions. Poor recovery leads to bagging and loss of shape, causing customer dissatisfaction.

Quality activewear maintains compression and support through repeated use. At our manufacturing facility, we prioritize these tests during development. Using high-quality materials like advanced spandex blends ensures consistent performance.

Consequences of Poor Performance

Inadequate stretch recovery causes multiple business problems. Immediate effects include product returns and negative reviews. Customers expect activewear to maintain its shape and support through regular use and washing.

Garments with poor recovery require frequent replacement, shortening product lifecycles. This damages brand reputation and customer loyalty. Implementing strict quality control from fabric selection prevents these issues.

Benefits of Proper Testing

Superior stretch characteristics enhance user experience significantly. Good recovery ensures consistent fit and comfortable movement. The fabric moves with the body during activity while maintaining its shape.

Reliable performance builds brand trust and customer satisfaction. Durable garments that maintain their appearance encourage repeat purchases. This justifies investment in thorough testing protocols.

Standard Testing Methods

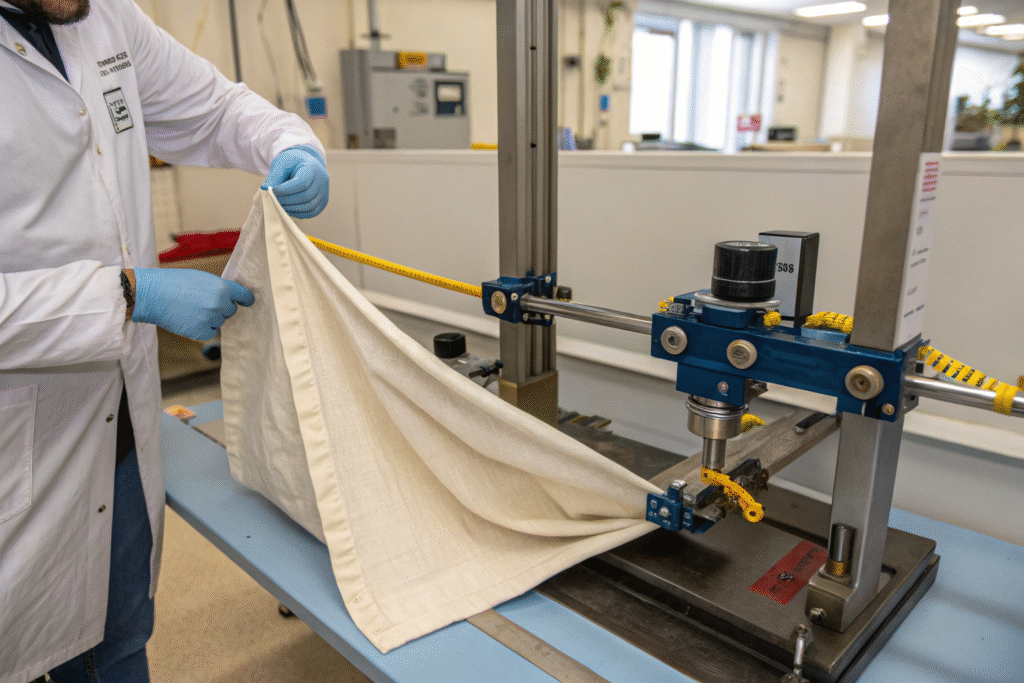

Industry professionals use standardized procedures for accurate results. The constant-rate-of-extension test measures fabric extension under controlled tension. This provides precise data about material behavior under stress.

Growth measurement tests evaluate recovery characteristics. The fabric is stretched and held before release, with recovery percentage calculated. International standards ensure consistent testing methodology across different laboratories.

Measuring Elongation

Elongation percentage quantifies fabric stretch capacity. Testing machines measure how much material extends before reaching breaking point. Different activities require varying elongation ranges for optimal performance.

Regular testing ensures consistent quality across production batches. Documentation provides evidence of compliance with specifications. This data helps brands select appropriate materials for their specific needs.

Equipment Functionality

Tensile testers provide objective performance data. These machines generate stress-strain curves showing fabric behavior throughout testing. The information helps predict real-world performance and durability.

Advanced equipment detects subtle quality variations. This allows for precise quality control and consistent product standards. Regular calibration ensures measurement accuracy over time.

Recovery Evaluation

Fabric recovery determines long-term garment integrity. Cyclic testing simulates repeated wear by stretching fabric multiple times. The permanent growth percentage indicates recovery quality after cycling.

High-quality activewear shows minimal permanent deformation. This ensures garments maintain their shape through extensive use. Regular monitoring helps maintain consistent production standards.

Recovery Timing

Immediate recovery affects garment fit during activity. Delayed recovery determines how fabric behaves between uses. Both characteristics influence overall product performance and customer satisfaction.

Optimal recovery balances quick response with lasting shape retention. Material composition and construction affect these properties. Understanding both aspects helps select appropriate fabrics.

Testing Duration

Cycle count should reflect expected product lifespan. More cycles provide better long-term performance prediction. Standards typically specify minimum cycles for different product categories.

Extended testing reveals material fatigue patterns. This helps identify potential failure points before production. Comprehensive testing prevents future quality issues.

Practical Quality Checks

Simple tests provide quick quality assessments before laboratory testing. The manual stretch test involves stretching fabric and observing recovery. Immediate return to original shape indicates good quality.

Wash testing evaluates performance under real-use conditions. Multiple cycles simulate long-term wear and cleaning effects. This helps identify potential issues before mass production.

Manual Testing

Basic stretch testing requires minimal equipment. Marking fabric before stretching helps visualize recovery. Slow or incomplete return suggests potential performance problems.

This method provides immediate feedback about fabric behavior. While not replacing laboratory tests, it helps screen obviously unsuitable materials quickly.

Wash Testing

Multiple wash cycles accelerate aging effects. Measuring dimensional changes after washing predicts long-term performance. This test particularly important for products requiring frequent cleaning.

Documenting changes helps make informed material selections. Comparing different materials under identical conditions provides valuable performance data.

conclusion

Thorough fabric testing ensures product success in competitive markets. Combining laboratory methods with practical checks provides comprehensive quality assessment. Understanding test results helps select optimal materials.

Proper evaluation reduces returns and builds brand reputation. Investing in testing ultimately saves costs and enhances customer satisfaction. This approach demonstrates commitment to quality.

Partnering with experienced manufacturers ensures reliable results. Our facility maintains rigorous testing standards for all production. Contact our team to discuss your specific fabric testing requirements.

Reach our Business Director Elaine at elaine@fumaoclothing.com for professional assistance. We provide comprehensive testing and manufacturing solutions for activewear brands.