As an experienced fabric manufacturer based in Keqiao's textile hub, I've witnessed how yarn spinning technology choices directly influence final fabric quality. International clients, particularly American buyers like Ron, express deep concerns about fabric performance - especially pilling issues affecting garment durability and customer satisfaction. Mastering core manufacturing processes proves essential for quality and cost control.

Yarn spinning methodology - specifically comparing air-jet versus ring spinning - substantially impacts fabric pilling behavior. Ring-spun yarns typically create smoother, stronger yarns with minimal fiber protrusion, delivering superior pilling resistance. Conversely, air-jet spun yarns, despite faster production and cost efficiency, often demonstrate harder hand feel and increased pilling susceptibility due to structural differences. For quality-focused buyers, this distinction becomes crucial for product development success.

Let's examine both spinning techniques thoroughly. We'll explore their operational mechanisms, direct pilling implications, and optimal yarn selection strategies to ensure your final products achieve peak performance standards and customer satisfaction.

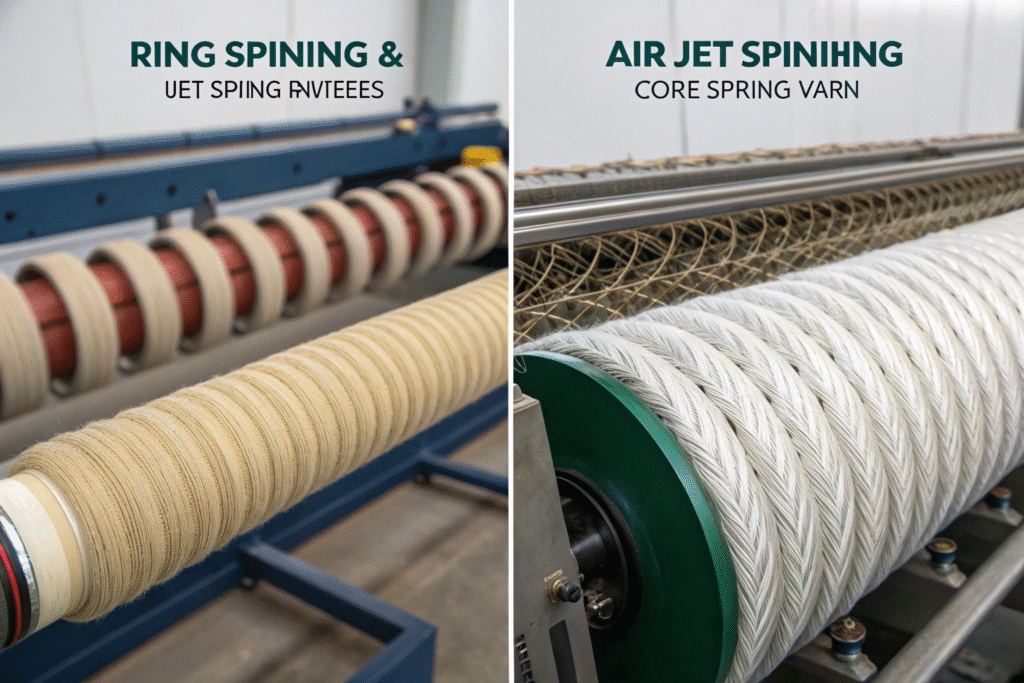

Fundamentals of Ring Spinning Technology

Ring spinning represents one of the oldest, most widely adopted yarn creation methods, renowned for producing premium-quality yarn with exceptional characteristics. The process involves multiple crucial steps transforming raw fibers into continuous, twisted yarn. Initially, fibers undergo drafting - straightening and attenuation. Subsequently, twist insertion occurs through rotating spindles and travelers moving around rings, generating uniformly strong yarn.

This spinning method yields yarn featuring firmly twisted helical fiber formations. The resulting structure appears densely compact. Yarn surfaces show exceptional smoothness with minimal protruding fibers. This versatile technique accommodates diverse fiber lengths, from short-staple cotton to long-staple wool. Final yarn demonstrates outstanding strength, smooth texture, and premium hand feel - making it the preferred choice for high-end apparel manufacturing.

What makes ring spinning produce stronger yarn?

Ring spinning generates enhanced yarn strength through unique twist insertion mechanics. During fiber drafting, materials pass through roving frames. High-speed spindle rotation winds yarn onto bobbins. Travelers - small C-shaped clips - create essential tension and twist by dragging behind spindles. This continuous twisting action binds fibers throughout their length, generating substantial inter-fiber friction and cohesion. The resulting yarn structure demonstrates remarkable compactness, with fibers maintaining parallel, tightly-wound alignment. This organized binding directly correlates with improved tensile strength. For durability-conscious buyers, particularly those manufacturing denim or performance wear, this strength advantage becomes paramount. Our internal CNAS-accredited testing laboratory consistently verifies ring-spun yarn superiority against international benchmarks like SGS standards, guaranteeing clients receive reliably superior fabric.

Why do premium apparel manufacturers prefer ring-spun yarn?

Premium apparel producers favor ring-spun yarn primarily for its exceptional softness and longevity. Tight, parallel fiber alignment creates impeccably smooth yarn surfaces. This smoothness translates into fabrics with luxurious hand feel - highly desirable for premium t-shirts, dress shirts, and undergarments. Furthermore, yarn strength ensures garments withstand repeated laundering and wearing without thinning or rupture. Another significant benefit involves superior pilling resistance. Minimal loose fiber ends on yarn surfaces reduce available material for pill formation during abrasion. This combination of comfort, durability, and appearance retention explains why luxury brands frequently specify ring-spun yarns. Our company's extensive natural fiber collection, featuring organic cotton and linen varieties, utilizes ring-spun yarns to deliver these premium qualities consistently.

Air-Jet Spinning Mechanics and Applications

Air-jet spinning constitutes a modern, rapid yarn formation technique employing compressed air jets for fiber twisting. Classified as an open-end spinning system, it operates differently than rotor spinning principles. The process commences with drafted fiber strands entering twisting chambers. Inside these chambers, dual nozzles project opposing air jets, generating vortices that wrap edge fibers around parallel fiber cores. This action binds strands into complete yarn.

This mechanism produces distinct yarn structures. Cores contain largely untwisted, parallel fibers. Surfaces comprise tightly twisted edge fiber wrappings securing core integrity. This configuration enables extremely fast, efficient production, dramatically increasing output while reducing manufacturing expenses compared to ring spinning. However, resulting yarns often exhibit stiffer hand feel and potential weakness, since binding depends on wrapper fibers rather than uniform cross-sectional twisting.

What primary benefits does air-jet spun yarn offer?

Air-jet spun yarn's chief advantages involve high production velocity and cost efficiency. The process significantly outpaces traditional ring spinning, enabling mills to produce greater yarn quantities in reduced timeframes. This operational efficiency directly translates to lower per-unit costs, creating attractive options for large-volume orders where budget considerations dominate. Additionally, air-jet spun yarns display high uniformity and excellent abrasion resistance in specific contexts, despite overall tensile strength limitations. They also demonstrate favorable dyeability characteristics, producing vibrant, clear coloration. For mass-market manufacturers and brands, these benefits present compelling arguments. Our agile supply network capitalizes on local spinning mill relationships to provide clients with both air-jet and ring-spun alternatives, ensuring optimal pricing and performance balance for specific market segments.

Which applications suit air-jet spinning best?

Air-jet spinning performs most effectively in products prioritizing manufacturing cost, production speed, and specific functional attributes over ultimate softness. Ideal implementations include home textiles like bed linens and pillowcases, where crisp, smooth finishes are desirable. It also sees extensive use in linings, interlinings, and certain technical/functional textiles where its structural properties provide inherent advantages. For example, in moisture-wicking fabric engineering, air-jet yarn's core-sheath configuration can sometimes enhance capillary action. However, it remains less appropriate for premium apparel demanding soft, comfortable hand feel. Understanding these application parameters helps our clients - from major brands to online store proprietors - make informed sourcing decisions aligning with product objectives and consumer expectations.

Spinning Methods and Fabric Pilling Relationship

Yarn spinning methodology fundamentally influences fabric pilling because it determines essential yarn architecture. Pilling develops when loose surface fibers entangle during wear and abrasion, forming small balls or "pills." Susceptibility directly relates to fiber security within yarn construction. Yarns with numerous loose, protruding fibers demonstrate higher pilling probability, since these loose ends easily extract and tangle.

Ring spinning manufactures yarn where fibers remain tightly twisted and embedded throughout their length. This leaves extremely few exposed fiber ends on surfaces. Contrastingly, air-jet spinning generates yarn where core fibers stay largely parallel and untwisted, secured only by surface wrapper fibers. This configuration facilitates core fiber extraction during friction, increasing pilling tendencies. Consequently, for pilling-resistant fabrics, spinning method selection requires careful consideration.

Which yarn properties affect pilling resistance?

Two primary yarn characteristics govern pilling resistance: protruding fiber quantity and yarn strength. Firstly, smooth-surfaced yarns with minimal protruding fiber ends exhibit reduced pilling likelihood. Simply stated, less available loose material exists for pill formation. Secondly, stronger yarns with high inter-fiber friction and cohesion better resist abrasive forces that extract fibers. Longer, finer fibers additionally contribute to improved pilling resistance, since they're more difficult to dislodge. This explains why fabrics crafted from long-staple pima cotton or Merino wool maintain renowned durability and clean appearance over time. Our product assortment emphasizes these superior natural fibers, processed with appropriate spinning technologies to satisfy global clients' high-quality demands.

Can finishing treatments minimize fabric pilling?

Indeed, fabric finishing techniques can substantially reduce pilling, though they cannot entirely overcome inherent tendencies established by yarn type. Common anti-pilling finishes include singeing (fabric surface burning to remove protruding fibers) and bio-polishing (enzymatic treatment selectively eliminating loose fibers). These processes effectively enhance short-term fabric pilling performance. However, fundamental yarn architecture remains the determining factor. Air-jet spun fabrics might display pilling improvement post bio-polishing, but ring-spun fabrics consistently demonstrate superior long-term resistance. We implement various finishing methods at partner facilities, including coating and specialized washes, to improve fabric performance and satisfy specific client requirements for quality and endurance.

Selecting Optimal Spinning Method for Your Product

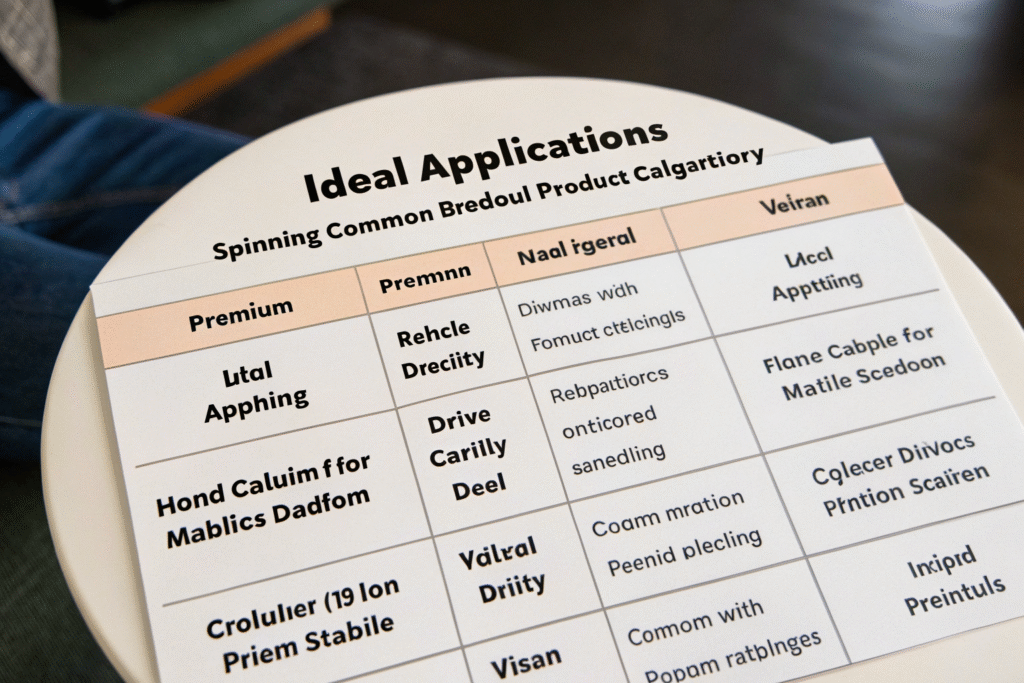

Choosing between air-jet and ring spinning entirely depends on your product priorities, target audience, and financial constraints. No universally "superior" option exists - only the most suitable selection for particular applications. The decision represents a classic compromise: ring-spun yarn's exceptional quality and comfort versus air-jet spun yarn's economic efficiency and speed. Determining the optimal choice requires clear comprehension of customer expectations and final garment performance demands.

To simplify this selection process, consider your product's primary purpose. Is it premium fashion where hand feel and durability dominate? Or volume-driven basics where cost and rapid turnaround prevail? The subsequent table delineates ideal applications for each spinning method across common product categories.

| Product Category | Recommended Spinning Method | Key Reasoning |

|---|---|---|

| Premium T-Shirts & Underwear | Ring Spinning | Superior softness, strength, and high pilling resistance for comfort and longevity. |

| High-End Denim & Shirts | Ring Spinning | Excellent durability and ability to develop authentic wear patterns over time. |

| Home Textiles (e.g., Sheets) | Air-Jet Spinning | Provides a smooth, crisp finish at a cost-effective price point for large volumes. |

| Technical Sportswear Linings | Air-Jet Spinning | Cost-effective and can be engineered for specific functional properties like moisture management. |

| Budget-Friendly Fashion | Air-Jet Spinning | Allows for lower retail pricing while maintaining acceptable quality for short-term use. |

How can I choose yarn for long-lasting, pill-resistant fabric?

Selecting yarn for durable, pill-resistant fabric necessitates prioritizing ring-spun varieties, particularly those comprising long-staple fibers. Begin by specifying ring-spun cotton, wool, or their blends for your material. Seek suppliers providing yarn quality evidence, such as certified laboratory test reports. Inquire about fiber provenance - long-staple Egyptian cotton or high-grade wool inherently produce stronger, smoother yarn. Additionally, ascertain whether fabrics will receive anti-pilling finishes like bio-polishing for extra protection. As manufacturers with integrated weaving and dyeing capabilities, we assist clients throughout this precise selection journey, ensuring chosen raw materials match their vision for premium, enduring final products.

What spinning-related questions should I ask fabric suppliers?

You should pose specific, technical inquiries to fabric suppliers clarifying yarn construction and anticipated performance. Initially, directly question: "Is this fabric's yarn ring-spun or air-jet spun?" Subsequently, probe deeper: "What's the fiber content and staple length?" Thirdly, request empirical data: "Can you provide pilling test results (e.g., ICI Pilling Box or Martindale tests) for this material?" Fourthly, investigate finishes: "Has this fabric received anti-pilling or bio-polishing treatments?" Finally, for American importers like Ron, crucial questioning involves: "How does fabric composition influence tariff expenses under current trade regulations?" Professional suppliers, like our Fumao team, maintain this information readily accessible. Our dedicated customer service focuses on delivering transparent, comprehensive responses to these vital questions, guaranteeing your import confidence regarding both quality and shipping logistics.

Conclusion

Selecting between air-jet and ring spinning constitutes a fundamental decision directly shaping fabric quality, performance, and expense. Ring spinning excels through superior yarn strength, softness, and exceptional pilling resistance, establishing it as the preferred choice for high-quality, durable apparel. Air-jet spinning alternatively offers remarkable production velocity and cost reduction, ideal for volume-focused products where specific hand feel proves less critical. No universal solution exists, but comprehending core distinctions and their consequences enables informed choices matching brand principles and consumer expectations.

Your fabric partner should provide clear, expert guidance through these technical details. At Fumao Fabric, we leverage profound Keqiao textile cluster roots and twenty-plus years' experience to deliver precisely this insight. We transcend simple fabric sales by co-creating value through ensuring appropriate materials for your success. Should you seek reliable collaboration for producing premium, pill-resistant clothing orders confidently, we await your contact. For detailed discussion regarding your specific requirements, please reach our Business Director, Elaine, at elaine@fumaoclothing.com. Let's transform your vision into tangible reality.