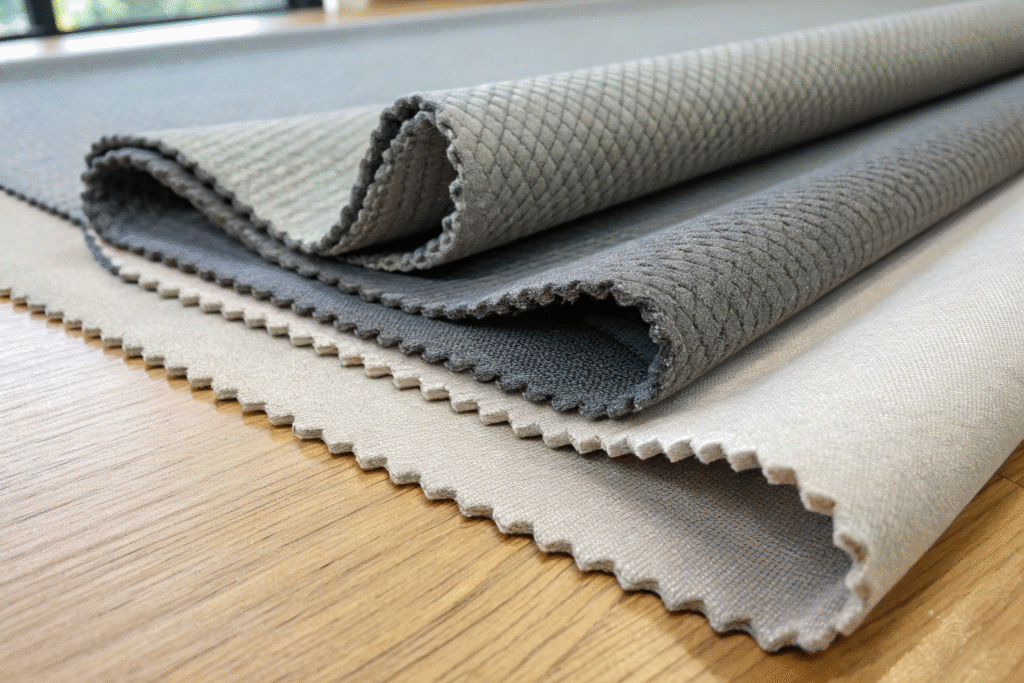

Having operated within Keqiao's textile ecosystem for twenty years, we've observed the remarkable evolution of athleisure wear. Industry professionals consistently seek guidance on selecting the optimal knit fabric that balances aesthetic appeal, wearing comfort, and functional performance. This analysis examines three predominant options to inform strategic decision-making.

The ideal fabric selection depends on achieving precise equilibrium among key characteristics. Single jersey delivers exceptional airflow for lightweight applications, interlock provides reliable stability for regular use, while Ponte fabric creates professional compression effects. Strategic choices must align with specific design objectives and performance requirements.

Essential Characteristics of Single Jersey Fabric

Manufactured using single needle bed construction, this ubiquitous knit features a smooth face and looped reverse side. Its distinctive architecture generates lightweight flexibility and notable stretch capabilities. The fabric's breathability represents a significant advantage in activewear applications.

Potential limitations include edge curling during cutting procedures and variable durability with inferior yarn quality. Performance enhancements typically incorporate synthetic fibers like polyester or spandex through specialized blending techniques.

Why Does Single Jersey Dominate Lightweight Athleisure?

Unparalleled skin comfort and economic efficiency drive its market prevalence. The material's soft texture suits loungewear perfectly, while advanced natural fiber blending technology ensures optimal thermal regulation during yoga sessions. Competitive production costs create accessible price points for consumers.

From manufacturing perspectives, single jersey supports efficient mass production. Our weaving facilities accommodate bulk orders while enabling small-batch customization for emerging brands. This adaptable supply chain helps companies respond swiftly to market trends.

Enhancing Single Jersey Durability for Sportswear

Fiber blending technology effectively addresses inherent limitations of pure cotton constructions. Standard 95% cotton/5% spandex combinations improve elastic recovery, whereas polyester-cotton-spandex blends optimize moisture management for intensive activities.

Innovative finishing techniques provide additional benefits. Single-side brushing creates thermal fleece interiors, while compact spinning produces smoother, more resilient surfaces. Our CNAS-certified laboratory conducts rigorous colorfastness verification to ensure compliance with activewear standards.

Strategic Applications of Interlock Knit

This double-faced construction utilizes back-to-back interlooping, creating identical smooth surfaces on both sides. The resulting fabric demonstrates increased thickness, superior stability, and minimal edge curling compared to single jersey variants.

Natural durability and shape retention make it suitable for transitional season garments. Although breathability measures lower than single jersey, its refined appearance bridges athletic and casual dressing contexts effectively.

Interlock's Advantages in Frequent-Wear Scenarios

Dual-layer construction underpins exceptional tear resistance. This characteristic makes it ideal for polo shirts and structured leggings undergoing repeated use. Excellent opacity prevents show-through in light-colored bottoms, addressing a common design concern.

The fabric's inherent drape communicates quality perception. Brands targeting premium positioning often select interlock for its smooth, wrinkle-resistant appearance that balances comfort with everyday resilience.

Climate Adaptation in Interlock Performance

Fiber composition critically influences environmental response. While 100% cotton delivers superior absorbency, it may retain moisture in humid conditions. Blended solutions offer versatile performance across climates through cotton-modal or cotton-polyester combinations.

Regenerated cellulose fibers like modal enhance softness and breathability. For active applications, recycled polyester integration improves moisture control and drying speed. Our proprietary Tencel™ blends deliver exceptional wicking performance with silk-like hand feel for year-round comfort.

Ponte Fabric's Professional Athletic Value

Known commercially as Ponte di Roma, this construction features notable stability and compression properties. Typical compositions combine polyester, rayon, and elevated spandex content, creating substantial weight with excellent recovery—ranking as the heaviest and most structured among the three options.

Superior wrinkle resistance and shape maintenance make it suitable for knit blazers and compression leggings. Its polished appearance facilitates seamless transition from athletic environments to professional settings.

Ponte's Compression and Shape Retention Mechanisms

High-density construction and elevated spandex content create its functional foundation. Compared to single jersey's 5-10% spandex, Ponte typically incorporates 10-20% or more, generating muscle support and compression benefits. Exceptional recovery prevents bagging in high-stress areas like knees.

Structural stability also benefits manufacturing processes. The fabric resists curling and distortion during cutting and sewing operations, resulting in cleaner construction and enhanced finished quality.

Considerations for Ponte Fabric Implementation

Weight and breathability trade-offs require careful evaluation. Heavier constructions may prove unsuitable for high-exertion activities in warm climates, while dense weaving limits air circulation. Advanced finishing technologies offer mitigation opportunities.

Our coating facility applies specialized moisture-wicking treatments to enhance sweat transport. Using high-tenacity microfibers enables development of lightweight Ponte variants that retain structural integrity. Our innovative biodegradable blends maintain performance while supporting global sustainable textile initiatives.

Efficient Sourcing Strategies for Chinese Knit Fabrics

China's market offers compelling advantages in cost efficiency and production scale, though supply chain navigation presents challenges. Identifying partners with transparent management systems becomes crucial, as quality inconsistencies and logistical delays represent common international procurement concerns.

Competent suppliers should deliver integrated services from sampling through mass production, implementing robust quality assurance and clear communication protocols to ensure timely receipt of specification-compliant materials.

Evaluating Fabric Supplier Quality Systems

Certified laboratory facilities form the foundation of quality assurance. Our CNAS-accredited testing center verifies each batch for shrinkage resistance and other key indicators, with QR code tracking enabling real-time quality monitoring. These measures support our 98% client acceptance rate.

Beyond certifications, inspection methodologies demand scrutiny. Dedicated quality teams conduct 100% inspection using light tables to identify and mark flaws before shipment, preventing defective materials from disrupting client production lines.

Optimizing Logistics and Tariff Management

Suppliers with direct access to logistical hubs provide distinct advantages. Leveraging the "Silk Road Keqiao" initiative and multimodal transport networks, we establish reliable global shipping solutions with competitive pricing.

For U.S. importers addressing tariff concerns, strategic sourcing planning proves essential. Our legal team provides expert guidance on rules of origin, utilizing Southeast Asian partnerships to optimize shipping routes and minimize duty expenses. Comprehensive documentation and customs clearance services ensure door-to-door delivery while mitigating potential risks.

Conclusion

Successful athleisure development requires precise understanding of fabric properties. Single jersey leads in lightweight breathability, interlock excels in durable versatility, while Ponte fabric offers professional compression benefits. Deep comprehension of each material's unique advantages, combined with target audience insights, enables creation of aesthetically pleasing and functionally superior products.

Ready to develop your next-generation athleisure collection? Partnering with full-service suppliers ensures complete supply chain integration. Our combined R&D, production, and quality control capabilities guarantee accurate realization of your design vision. Contact Business Director Elaine at elaine@fumaoclothing.com to explore collaborative opportunities.