Choosing the right fabric for your sportswear line can feel like a high-stakes game. Your customers demand comfort, durability, and performance, and the wrong material can lead to returns and damaged reputation. As a fabric supplier with over two decades in the heart of China's textile district, I've seen this dilemma play out countless times, especially between two popular choices: polyester spandex and nylon spandex.

So, which is best? The answer isn't one-size-fits-all. Polyester spandex is generally best for high-intensity, sweat-heavy activities due to its superior moisture-wicking and durability, while nylon spandex excels in softness, comfort, and flexibility, making it ideal for activities requiring a greater range of motion. The "best" choice ultimately depends on the specific sport, desired comfort level, and performance requirements of the final garment. Understanding their core differences is key to making a profitable decision for your brand.

Let's break down the complexities of these two powerhouse fabrics. We will compare their key properties side-by-side, explore their ideal applications, and guide you on how to source them efficiently for your sportswear line.

What are the key differences in durability?

When you're investing in bulk fabric for your activewear line, you need to know it will last. Durability directly impacts customer satisfaction and return rates. Both polyester and nylon are strong, but they have different strengths that affect how they withstand wear and tear.

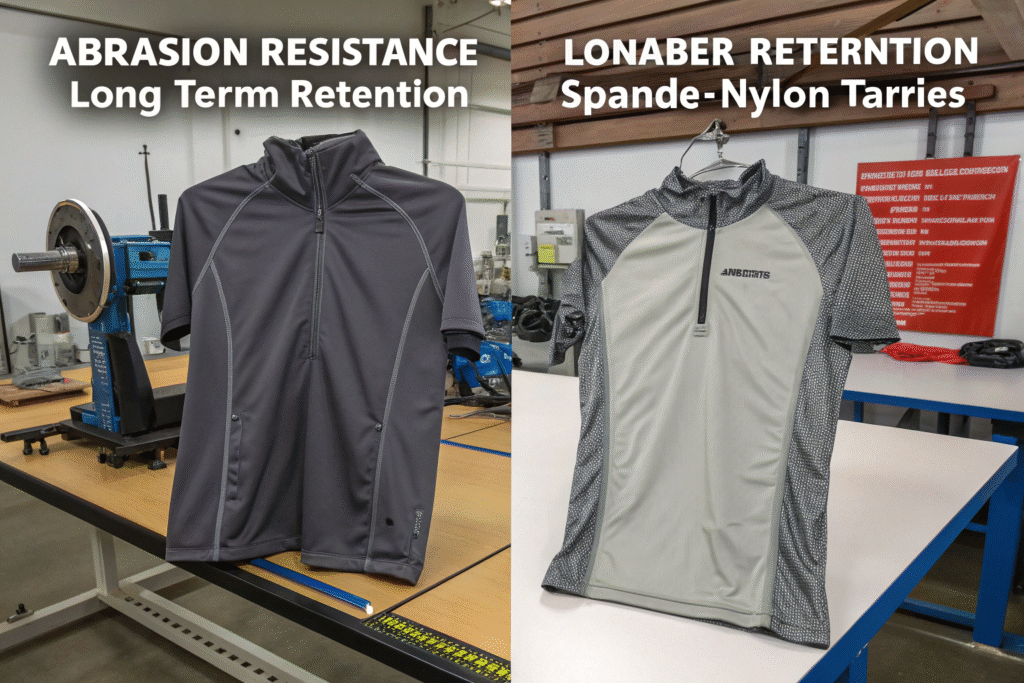

In terms of pure abrasion resistance and long-term shape retention, polyester spandex often has the edge. Polyester fibers are incredibly resilient against rubbing, scraping, and pilling. This means garments made from polyester spandex blends can withstand the friction from backpacks, gym equipment, and repeated washing cycles better than nylon. Nylon, while very strong, is generally more prone to pilling over time, especially in areas of high friction.

How does abrasion resistance affect my sportswear's lifespan?

Abrasion resistance is the fabric's ability to withstand surface wear from friction. Think of a cyclist's shorts rubbing against the bike seat or the inner thighs of leggings rubbing together. Polyester's molecular structure makes it inherently more resistant to this kind of damage. At Fumao, our CNAS-certified lab rigorously tests for this using Martindale and Wyzenbeek tests. We've found that high-quality polyester spandex fabrics can endure thousands of rub cycles before showing significant wear. This is why it's a top choice for hiking apparel, rugged training gear, and any application where the fabric will face consistent rough contact. For brands targeting the high-intensity functional training market, this is a critical factor.

Why is tensile strength important for performance wear?

Tensile strength refers to how much force a fabric can take before it tears. Here, nylon spandex is typically the stronger of the two. Nylon fibers have a higher tensile strength, meaning they can be stretched further before breaking. This exceptional "tear strength" is a major reason why nylon is the material of choice for products like stockings and lightweight outer shells where durability under tension is paramount. However, it's crucial to pair high tensile strength with proper fabric construction. We ensure this through our end-to-end quality control, where every meter is tested to meet international standards like those from SGS. This combination of strong fibers and robust manufacturing is what creates sportswear that won't fail during a deep lunge or a powerful stretch.

Which fabric offers better moisture management?

Moisture management is the heart of performance sportswear. No one wants to work out in a cold, soggy shirt. How a fabric handles sweat can make or break the athlete's experience. This is where the fundamental properties of the fibers come into play.

Polyester spandex is widely recognized as the champion of moisture-wicking. The hydrophobic (water-repelling) nature of polyester means it doesn't absorb water. Instead, it pulls sweat away from the skin to the outer surface of the fabric where it can spread out and evaporate quickly. This keeps the wearer drier and more comfortable during intense, sweat-heavy activities. Nylon, on the other hand, is somewhat absorbent, which can leave a feeling of dampness.

How does wicking keep athletes dry and comfortable?

Moisture-wicking is a transport mechanism. It's all about capillary action, where liquid moves through tiny tubes in the fabric. Polyester's inherent water-repelling property drives this process efficiently. When you are sourcing fabric, look for suppliers who offer advanced moisture-wicking finishes. At our weaving and dyeing partners, we apply specialized finishes that enhance this capillary action, ensuring sweat is moved away from the skin rapidly. This is a key feature for running tops, football jerseys, and any sportswear designed for cardio-intensive workouts. It prevents the chilling effect of sweat-soaked fabric and reduces chafing, directly addressing a major pain point for athletes.

What about drying time and odor resistance?

Drying time is closely tied to wicking. Because polyester doesn't hold onto water, garments made from polyester spandex typically dry much faster than those made from nylon. This is a huge advantage for travel, multi-session workouts, or outdoor activities where weather can change. Furthermore, polyester is less susceptible to odor-causing bacteria. Mildew and bacteria need moisture to grow, and since polyester is drier, it's a less hospitable environment. Nylon's slight absorbency can make it more prone to retaining odors if not treated with an antimicrobial finish. We develop such functional textiles in our own R&D lab, offering built-in odor control to enhance the performance of both polyester and nylon blends.

How do comfort and fit compare?

Beyond pure performance, sportswear must feel good on the skin. Comfort influences everything from focus during a workout to the likelihood of a customer becoming a repeat buyer. The feel and fit of the garment are dictated by the base fiber's characteristics and the fabric's construction.

Nylon spandex is often praised for its superior softness and comfortable, second-skin feel. It has a smoother, silkier hand feel compared to polyester. This makes it a perennial favorite for yoga wear, premium leggings, and base layers where direct skin contact and freedom of movement are paramount. Polyester has come a long way and can be made very soft, but nylon typically holds the top spot for luxurious comfort.

Which fabric provides a softer feel against the skin?

The softness comes down to the fineness of the yarn and the fiber's natural texture. Nylon filaments are generally smoother and more pliable than polyester, giving it that signature silky touch. For brands focused on yoga, Pilates, or luxury loungewear, this is a significant selling point. However, innovation in textile engineering has blurred these lines. Through advanced spinning techniques and brushing finishes, we can now produce polyester spandex fabrics that rival the softness of nylon. It's important to discuss the desired hand feel with your supplier and request physical fabric swatches to feel the difference yourself.

What is the range of motion offered by each?

The range of motion is primarily provided by the spandex (elastane) component in the blend. Both fabrics contain spandex, typically ranging from 10% to 20%. However, the combination of nylon's natural give and spandex creates an exceptionally flexible fabric. Nylon has a higher elongation-at-break, meaning it can stretch further before reaching its limit. This superior recovery helps the garment maintain its shape and hug the body without feeling restrictive. This is critical for disciplines like gymnastics, dance, or power yoga that involve extreme stretching. Our quality control process includes rigorous testing for elastic recovery to ensure the fabric snaps back after stretching, wash after wash.

Which is more cost-effective for bulk orders?

For any business, the bottom line is crucial. The cost of materials directly impacts your profit margins and final product pricing. Understanding the cost drivers for each fabric will help you make a financially sound decision that doesn't compromise on quality.

Polyester spandex is generally the more cost-effective option for bulk sportswear orders. The raw materials for polyester are derived from petroleum, and the global production scale is massive, leading to lower prices. Nylon is typically more expensive to produce, which translates to a higher cost per meter. However, this initial cost must be weighed against the perceived value and performance benefits for your target market.

How do raw material costs influence the final price?

The price of crude oil is a major factor, as both are synthetic fibers. However, the chemical process for creating nylon polymer is more complex than for polyester, which inherently makes it more expensive. Furthermore, the cost can fluctuate based on the type of nylon (e.g., Nylon 6,6 vs. Nylon 6). At Fumao, we leverage our position in the Keqiao textile cluster to secure raw materials at competitive prices, which helps us manage costs for our clients. We also offer a wide range of options in both fibers, allowing you to select a quality level that fits your budget without sacrificing the core performance your customers expect.

What about production efficiency and lead times?

Production efficiency directly affects cost and timeliness. Polyester is often easier and faster to dye and finish than nylon, leading to shorter production cycles. This agility in the supply chain is a key advantage. Our integrated supply chain, from weaving to dyeing to finishing, is optimized for speed. We offer 48-hour sample development and quick bulk delivery, which is accelerated by our local partnerships. This efficiency reduces overall lead times, helping you get your products to market faster. For businesses concerned about sailing schedules and timeliness, a reliable and fast supply chain is as valuable as a low price per meter. Our diversified logistics network ensures export resilience and reliable doorstep shipping to the U.S., mitigating the risks of delays.

Conclusion

The debate between polyester spandex and nylon spandex doesn't have a single winner. Your choice should be a strategic one, aligned with your brand's specific needs. If your priority is durability, moisture-wicking, and cost-effectiveness for high-intensity activities, polyester spandex is your champion. If you are aiming for superior softness, exceptional comfort, and flexibility for low-to-medium impact wear, then nylon spandex is the ideal candidate. Many successful brands even use both, selecting the fabric based on the specific garment's purpose.

At Fumao Textiles International, we don't just sell fabrics; we co-create value. We understand that your success depends on getting the right materials, with consistent quality, delivered on time. With over 20 years of expertise, a CNAS-certified lab for guaranteed quality, and an agile supply chain built for speed, we are your trusted partner in Asia. We provide seamless one-stop customization, from lab dips to tech packs, for all your sportswear fabric needs.

Ready to produce high-performance sportswear that your customers will love? Let's discuss your next project. Contact our Business Director, Elaine, today at elaine@fumaoclothing.com to request free fabric swatches and get a competitive quote for your bulk order.