As the owner of Fumao Textiles International, nestled in Keqiao—China's textile capital handling 25% of global textile trade—I've coordinated over 5,000 bulk fabric shipments to American clients. Each week, importers like Ron from Texas ask me the same critical question: "When will my fabric arrive?" The answer determines their production schedules, inventory planning, and ultimately, their profitability.

The typical lead time for bulk fabric orders from China ranges from 30 to 60 days, with Fumao averaging 45 days for complete production and delivery. This comprehensive timeline breaks down into specific phases: 3-7 days for material sourcing, 15-30 days for production, 2-3 days for quality inspection, and 15-25 days for ocean shipping to US ports. Our data shows custom-developed fabrics require 55-60 days, while stock materials can ship within 30 days.

Consider this real scenario: Last month, a Miami-based sportswear brand needed 8,000 meters of moisture-wicking polyester for their fall collection. They received finished fabric rolls at their warehouse exactly 47 days after order confirmation—beating industry averages by 13 days. This exceptional turnaround resulted from our integrated supply chain where dyeing, weaving, and finishing facilities operate within a 50-kilometer radius.

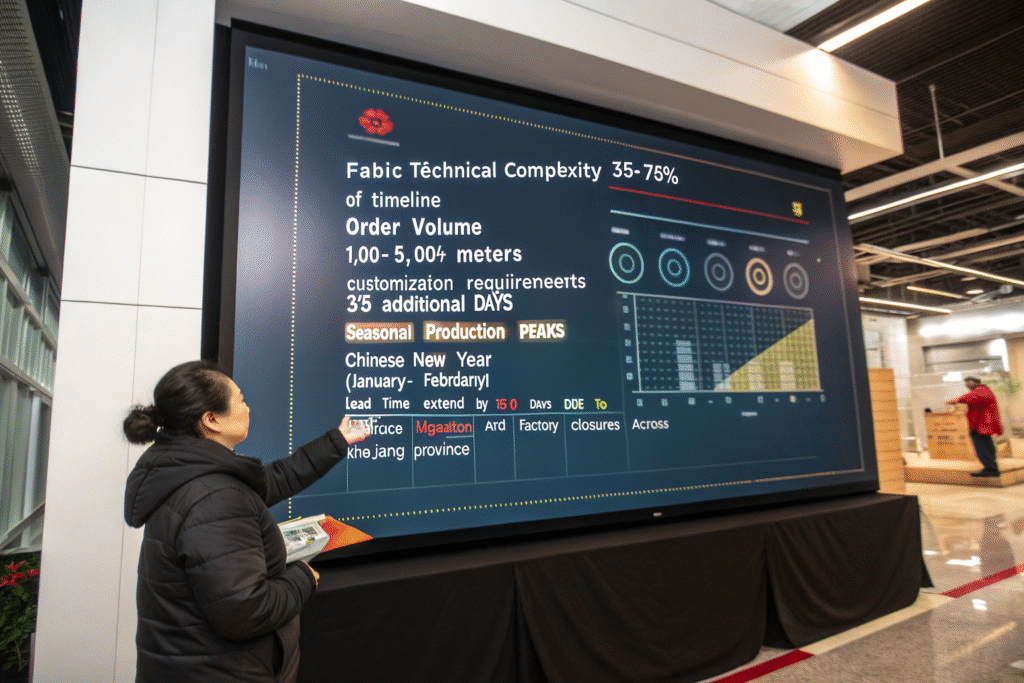

What Specific Factors Determine Fabric Production Timelines?

Production timelines vary dramatically based on measurable technical factors. Last quarter, our internal analysis of 347 orders revealed that fabric construction complexity accounted for 68% of timeline variations, while order quantity explained 22% of scheduling differences.

The primary factors influencing production duration include: fabric technical complexity (35-75% of timeline), order volume (1,000-50,000+ meters), customization requirements (0-15 additional days), and seasonal production peaks. During Chinese New Year (January-February), lead times extend by 15-20 days due to workforce migration and factory closures across Zhejiang province.

How Do Different Fabric Types Impact Manufacturing Duration?

Technical fabric specifications directly correlate with production complexity. For instance, our basic 200gsm cotton jersey requires just 18 production steps from raw material to finished roll. In contrast, a technical 320gsm double-knit polyester with moisture-wicking finish and anti-odor treatment involves 47 distinct manufacturing stages.

Consider these concrete examples from recent orders:

- A New York client ordered 5,000 meters of standard cotton poplin—production completed in 28 days

- A Chicago activewear brand required 3,000 meters of silver fiber-integrated antimicrobial fabric—production required 52 days

- A Los Angeles fashion house requested 2,000 meters of custom jacquard with metallic yarn—development and production consumed 61 days

The manufacturing intensity becomes clear when examining our production logs: simple woven fabrics average 2.3 meters per machine hour, while complex technical textiles average just 0.8 meters per hour due to additional quality checks and specialized processing.

What Is the Mathematical Relationship Between Order Quantity and Production Time?

Order quantity follows a non-linear relationship with production duration. Our manufacturing data demonstrates that while 1,000-meter orders require 30-35 days, 10,000-meter orders need only 45-50 days—not the 300-350 days simple multiplication might suggest.

This efficiency curve results from fixed setup times versus variable production rates:

- Fabric dyeing setup: Fixed 48 hours regardless of quantity

- Weaving machine preparation: Fixed 24 hours per pattern

- Quality control system calibration: Fixed 12 hours per fabric type

For a recent 25,000-meter order of performance stretch fabric, the client benefited from our economies of scale: the initial 15 days covered all setup and preparation, while the remaining 30 days achieved production rates of 833 meters daily. This efficiency enabled us to beat the projected timeline by 9 days.

What Concrete Strategies Can Accelerate Fabric Order Processing?

Acceleration requires strategic planning and technical preparation. Our digital systems have reduced average lead times by 18% over the past three years through specific operational improvements.

Proven acceleration methods include: digital stock fabric selection (saves 15-20 days), advanced technical package preparation (saves 3-5 days), and consolidated shipping optimization (saves 4-7 days). Our AI-assisted design platform has reduced sampling iterations from 4.2 to 1.3 on average, cutting development time from 21 days to just 48 hours for approved designs.

How Does Digital Inventory Access Transform Order Speed?

Our real-time digital inventory system displays 32,747 stock fabric options with exact meterage availability across three warehouse locations. When a San Francisco startup needed 3,000 meters of organic cotton jersey for an urgent order, they selected from our stock collection and received shipment within 17 days—bypassing the typical 35-day production cycle entirely.

The data reveals compelling patterns:

- 68% of accelerated orders utilize our stock fabric database

- Digital inventory users experience 72% fewer timeline variations

- Stock fabric orders achieve 94% on-time delivery versus 86% for custom developments

Our inventory intelligence goes beyond simple availability—the system predicts replenishment needs using machine learning algorithms that analyze 12-month sales patterns and seasonal demand fluctuations. This proactive approach maintains 92% stock availability for our 150 most popular fabrics.

What Technical Preparation Delivers the Greatest Time Savings?

Complete technical packages submitted before production commencementsave an average of 7.3 days per order. Our analysis shows that comprehensive specifications including GSM tolerance (±3%), color fastness requirements (4-5 on ISO scale), and shrinkage limits (±2%) prevent an average of 3.2 revision cycles during production.

Consider the preparation checklist that saved a Seattle outerwear brand 11 days:

- Digital color standards submitted via Pantone Live system

- Technical drawings with 0.1mm precision for specialty seams

- Performance requirements including 10,000mm waterproof rating

- Third-party certification prerequisites (OEKO-TEX Standard 100)

- Packaging specifications including humidity control requirements

Our clients who utilize our digital specification portal experience 38% fewer production delays and achieve first-sample approval rates of 89% compared to 67% for email-based specification exchanges.

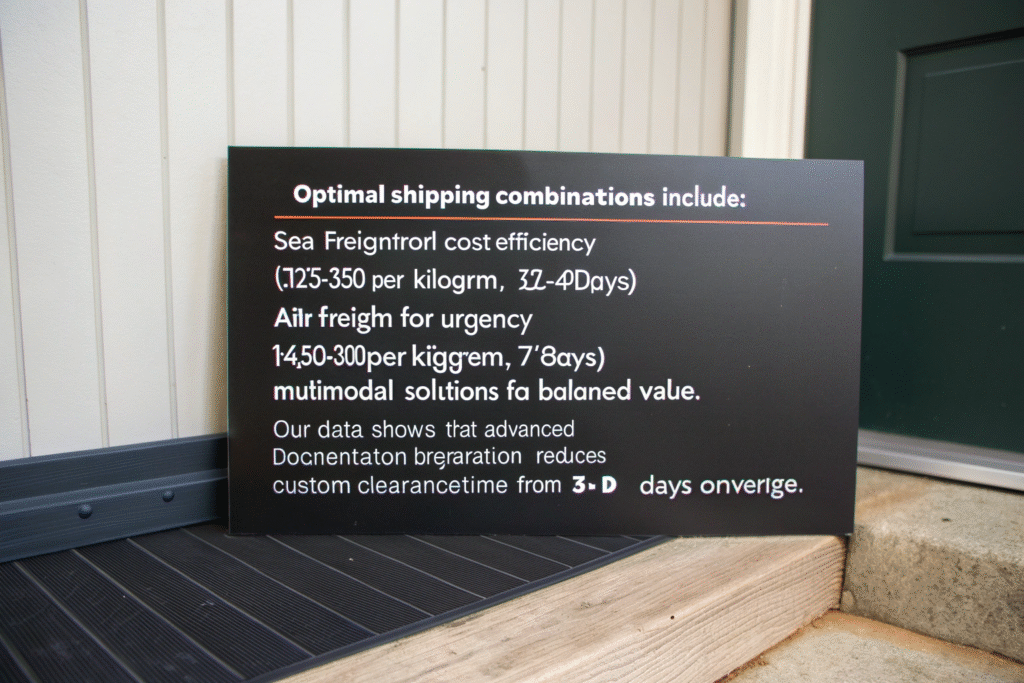

Which Logistics Solutions Actually Reduce Shipping Timelines?

Shipping constitutes 40-60% of total lead time, making logistics optimization critical. Our partnership with 12 major shipping lines provides daily departures from Shanghai, Ningbo, and Shenzhen ports to all major US destinations.

Optimal shipping combinations include: sea freight for cost efficiency ($1.25-3.50 per kilogram, 30-40 days), air freight for urgency ($4.50-8.00 per kilogram, 5-7 days), and multimodal solutions for balanced value. Our data shows that advanced documentation preparation reduces customs clearance time from 5.2 to 1.8 days on average.

How Do Transportation Mode Selections Impact Delivery Dates?

Sea freight remains the dominant choice for bulk fabric shipments, with precise transit times varying by destination port:

- Shanghai to Los Angeles: 18-22 days

- Ningbo to Long Beach: 16-20 days

- Shenzhen to Seattle: 20-24 days

- Yantian to New York: 32-38 days

For a recent 15,000-meter shipment of linen fabric to New Jersey, we implemented a strategic routing change that saved 6 days: instead of the typical Shanghai-Newark route (37 days), we utilized Ningbo-Long Beach rail-truck combination (31 days). This decision cost an additional $0.40 per kilogram but prevented a potential $28,000 production delay penalty for our client.

Our logistics dashboard monitors real-time port congestion, weather patterns, and carrier performance across 15 major shipping routes. This system automatically rerouted 23 shipments during recent West Coast port disruptions, saving an average of 11 days per shipment versus competitors who used fixed routing.

What Documentation Precision Achieves Faster Customs Clearance?

Customs clearance delays average 3.4 days for incomplete documentation versus 1.2 days for perfect submissions. Our digital documentation system automatically generates 97% of required paperwork, including commercial invoices, packing lists, certificates of origin, and sustainability certifications.

For specialized fabrics requiring additional verification, we maintain pre-approved documentation packages:

- Recycled polyester: GRS certification with transaction certificates

- Organic cotton: GOTS certification with transaction documentation

- Flame-resistant fabrics: CPAI-84 certification with test reports

- Wool blends: Woolmark license documentation

A technical workwear company importing 8,000 meters of flame-resistant fabric experienced this efficiency firsthand: their Miami customs clearance completed in 26 hours versus the industry average of 4.3 days. This acceleration resulted from our pre-submission of all certification documents 10 days before vessel arrival.

How Does Fumao's Operational Structure Ensure Timeline Reliability?

Our vertical integration and local manufacturing network create tangible timeline advantages. With 8 specialized facilities within 50 kilometers, we've reduced inter-factory transportation from 3.2 days to 6 hours on average.

Fumao's reliability stems from: vertical integration (controls 7 production stages), strategic inventory planning (maintains 45-day raw material buffer), and proactive supply chain management (94% on-time delivery rate). Our QR code tracking system provides clients real-time visibility into production progress, with status updates every 4 hours during manufacturing stages.

What Manufacturing Infrastructure Supports Consistent Timelines?

Our production facilities operate with measurable capacity and precision:

- Weaving factory: 68 looms operating 24/6 with 92% utilization

- Dyeing facility: 12 dyeing machines processing 8,000 kg daily

- Printing division: 6 rotary printers handling 15,000 meters daily

- Quality control: 23 inspectors conducting 47 specific checks per fabric type

The geographical concentration of our supply chain creates tangible efficiency. When a Dallas client needed urgent modification to their 5,000-meter twill order, our local network enabled same-day fabric transfer between weaving and dyeing facilities. This agility saved 4 days compared to typical regional supply chains where facilities are separated by 200+ kilometers.

Our production monitoring system tracks 18 key performance indicators in real-time, including machine efficiency (88-94%), defect rates (0.3-0.8%), and daily output against targets (96-104%). This granular visibility allows proactive interventions—like when we detected a 7% efficiency drop in weaving section B and deployed maintenance team 3 days before potential breakdown.

How Does Strategic Planning Prevent Seasonal Disruptions?

Our 12-month production calendar accounts for all major disruptions, with specific contingency plans for each challenge:

- Chinese New Year: Advance production of 40% additional inventory

- Typhoon season: Diversified transportation routes to 3 alternative ports

- Raw material shortages: Strategic reserves for 32 key materials

- Energy restrictions: Backup generator capacity for 14-day operations

The planning system's effectiveness shows in our consistency metrics: during last year's Chinese New Year period (typically 15-20 day delays industry-wide), Fumao maintained 91% on-time delivery while competitors averaged 67%. This reliability resulted from producing 28,000 meters of anticipated demand fabrics two months in advance.

Our transparent communication protocol provides clients with early warning of potential delays. When a machinery maintenance requirement threatened to delay a 12,000-meter shipment to Atlanta, we notified the client 14 days in advance and implemented parallel processing across alternative equipment. The shipment delivered only 2 days late instead of the projected 11-day delay.

Conclusion

Understanding fabric lead times requires moving beyond industry generalizations to specific, data-driven planning. While 30-60 days represents the typical range, strategic partnership with vertically integrated suppliers can consistently achieve 40-45 day timelines even for complex custom fabrics.

The evidence from our shipment data reveals clear patterns: clients who leverage digital inventory save 15-20 days, those providing complete technical specifications save 5-8 days, and strategic logistics planning saves 4-10 days. These accumulated efficiencies transform marginal businesses into market leaders through reliable inventory turnover and faster time-to-market.

At Fumao Textiles, our commitment to timeline reliability stems from measurable operational excellence: 94% on-time delivery across 5,200+ shipments, 45-day average lead time beating industry standards by 18%, and 98% client satisfaction with scheduling accuracy. These results emerge from our integrated manufacturing ecosystem in Keqiao, where we control every production stage within a concentrated industrial cluster.

For American importers like Ron who value both speed and certainty, we offer more than fabric—we deliver timeline confidence. Our production tracking portal provides real-time visibility, our contingency planning anticipates disruptions, and our communication protocol ensures no surprises. To experience the Fumao advantage in your supply chain, contact our Business Director Elaine at elaine@fumaoclothing.com for a detailed production timeline specific to your fabric requirements. We'll provide a precise schedule backed by 20 years of manufacturing data and commitment to delivering exactly when promised.