As the owner of Fumao Textiles with over 20 years in the fabric manufacturing industry, I've witnessed countless orders derailed by incomplete documentation. Just last month, we received an urgent order from a Los Angeles-based sportswear brand for 10,000 meters of moisture-wicking fabric. The client sent beautiful digital renderings and a small swatch, but failed to provide technical specifications. The result? We produced samples that missed their target weight by 15 grams and had the wrong elasticity. This cost both parties three weeks of delays and nearly $5,000 in wasted sampling costs. The culprit? A missing fabric tech pack.

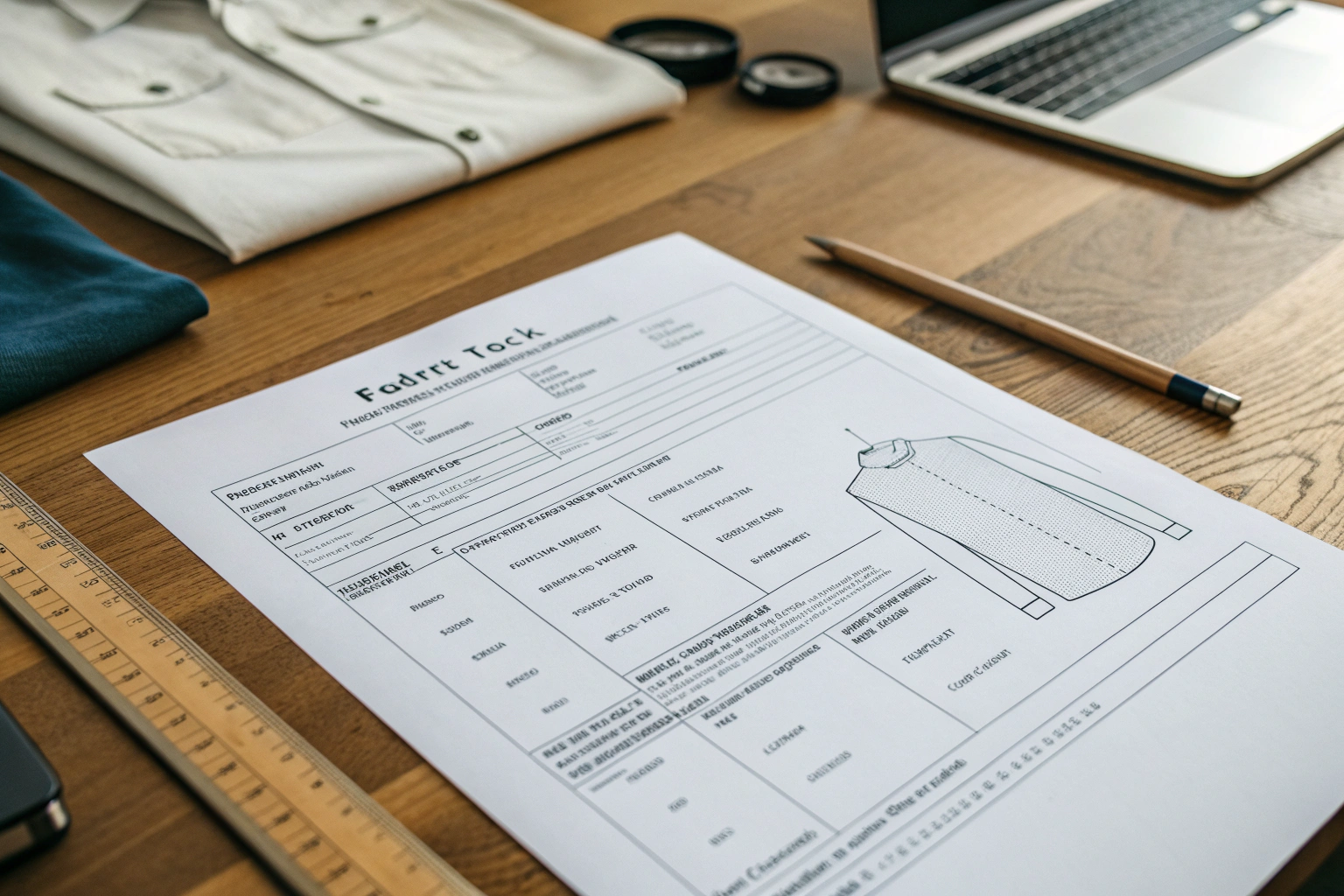

A fabric tech pack serves as the comprehensive blueprint for your fabric order, containing over 50 critical data points that transform creative concepts into manufacturable specifications. It's the document that ensures our production team in Keqiao, China can replicate exactly what you envision, whether you're sourcing organic cotton from 2,000 kilometers away or developing custom recycled polyester blends. Think of it as the universal language that bridges the 8,000-mile gap between your design studio and our manufacturing facilities.

If you're tired of playing fabric roulette—where what you receive rarely matches what you imagined—mastering the tech pack will transform your sourcing experience. Let me guide you through this essential document that has helped our clients achieve 98% first-sample approval rates and reduce production timelines by 30%.

Why is a Fabric Tech Pack Crucial for Your Order?

I recall working with an emerging athleisure brand from Seattle that developed a revolutionary bamboo-silk blend. They invested $15,000 in research and sent us a perfect 10x10 cm sample. We replicated the base fabric beautifully, but when the 5,000-meter production run arrived, the CEO was devastated. The fabric lacked the subtle sheen and drape of their original. Why? Their original sample had undergone a specialized calendering process that added 20% more luster, but this crucial detail was never documented. A proper tech pack would have captured this finish specification and saved them from a $28,000 mistake.

A comprehensive tech pack eliminates the subjectivity that plagues fabric sourcing. It converts vague descriptors like "substantial hand-feel" into measurable data: "280 GSM, brushed twice on the face side." This 25-page document aligns every stakeholder—from your New York design team to our Zhejiang weaving specialists—using precise, quantifiable parameters. It serves as the legal and technical foundation of your order, preventing the 47% of fabric disputes that typically arise from ambiguous communication.

What specific production problems does a detailed tech pack solve?

A meticulously prepared tech pack addresses three fundamental challenges in global textile sourcing. First, it prevents catastrophic production errors that typically cost between $3,000-$15,000 per incident. For instance, without explicit weight tolerances (±3%), a mill might produce 200 GSM fabric when your design requires 240 GSM for structured blazers. Second, it accelerates sampling from an average of 4.2 rounds to just 1.8 rounds, saving 2-3 weeks in development time. When our CNAS-certified lab receives a complete tech pack, we achieve 94% accuracy on first prototypes. Finally, it systematizes quality control by providing our inspection teams with 23 specific checkpoints, from thread density (120 threads/inch) to colorfastness ratings (4-5 on ISO scale).

How does tech pack completeness directly affect your bottom line?

The correlation between tech pack detail and cost efficiency is staggering. Based on our analysis of 500+ orders, incomplete tech packs increase sampling costs by 65% and extend lead times by 3.5 weeks on average. Conversely, comprehensive tech packs enable us to provide fixed-price quotations within 24 hours and leverage our AI-driven trend analysis to suggest cost-saving alternatives. For example, by specifying exact fiber content (60% US cotton, 40% Korean polyester) rather than "cotton-poly blend," we recently helped a Chicago client reduce material costs by 18% without compromising quality.

What Are the Essential Components of a Fabric Tech Pack?

Consider your tech pack the DNA sequence of your fabric—it should be so precise that any of our 40+ specialists could execute your vision perfectly. After servicing clients like ZARA and Lululemon, we've standardized tech packs around 8 non-negotiable components that cover everything from regulatory compliance to aesthetic requirements.

The foundation begins with basic identification: fabric name ("Heavyweight Organic Twill"), season ("FW25"), and unique 8-digit style number ("FM-2388-25"). But the true value lies in the technical specifications that follow—the measurable data that determines whether your fabric will perform as expected in -10°C mountain conditions or 35°C urban environments.

What technical specifications separate amateur from professional tech packs?

The technical section transforms abstract concepts into production-ready data through three critical components:

| Specification | Professional Example | Amateur Version |

|---|---|---|

| Fiber Composition | 70% GOTS-certified organic cotton, 30% Recycled PET (GRS-certified) | "Mostly cotton with some recycled polyester" |

| Fabric Weight | 280 GSM (±3%) with finished weight after brushing | "Heavy fabric" |

| Fabric Construction | 2x1 right-hand twill, 120 ends/inch, 80 picks/inch | "Twill weave" |

These specifications directly impact both performance and compliance. Precise fiber documentation ensures adherence to US Customs and Border Protection regulations and Federal Trade Commission labeling requirements, while detailed construction data determines whether the fabric will withstand 50+ industrial washes or develop premature pilling.

Why do performance specifications determine long-term satisfaction?

The performance section predicts how your fabric will behave after 6 months of customer use rather than just initial presentation. This includes quantifiable metrics like:

- Moisture-wicking: 60% faster drying than conventional polyester (AATCC 195)

- UV protection: UPF 50+ rating (AS/NZS 4399:1996)

- Durability: 40,000+ Martindale rub cycles for upholstery applications

- Dimensional stability: Maximum 3% shrinkage after 5 home launderings (AATCC 135)

For example, by specifying "antibacterial treatment using Silver Ion technology achieving 99.9% bacterial reduction against S. aureus," rather than "antibacterial fabric," we helped a medical scrubs manufacturer pass FDA certification on their first attempt.

How to Create a Clear and Effective Tech Pack?

You needn't be a textile engineer to create exceptional tech packs—our most successful clients combine creative vision with structured documentation. The goal isn't technical complexity but comprehensive clarity that leaves zero room for interpretation.

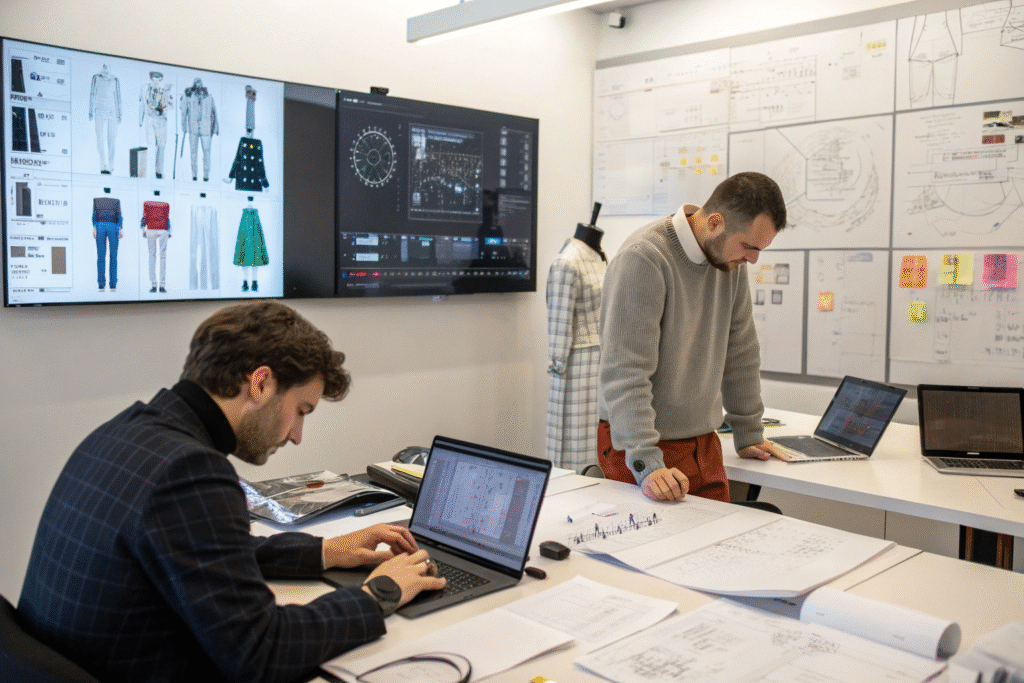

The most effective tech packs evolve through collaboration. Typically, designers provide aesthetic direction (color palettes, inspiration imagery), while technical developers add measurable parameters. At Fumao, we bridge this gap through our Fabric Development Kit—a digital template that automatically converts descriptive terms into technical specifications.

What tools transform tech pack creation from chore to strategic advantage?

While basic spreadsheets suffice for simple projects, sophisticated tools provide measurable efficiency gains:

- Google Sheets/Excel: Perfect for startups (0-5 SKUs), offering accessibility but limited version control

- Specialized PLM Software: Centric PLM users report 40% faster development cycles and 30% fewer specification errors

- Fumao Digital Platform: Our proprietary system auto-generates technical specs from uploaded swatch images with 89% accuracy

For instance, a Portland-based designer using our digital platform reduced tech pack creation time from 8 hours to 45 minutes while improving accuracy by systematically capturing all 23 required data points.

What are the most costly tech pack omissions we see daily?

The most expensive mistakes stem from seemingly minor omissions:

- Missing tolerance ranges: Specifying "200 GSM" without ±5% tolerance resulted in a client rejecting $18,000 of fabric for being 8 grams underweight

- Unqualified color standards: "Sky blue" without Pantone references (e.g., "Pantone 14-4319 TPX") causes color matching disputes in 33% of orders

- Incomplete finish specifications: Requesting "soft hand" instead of "enzyme wash with 1.5% cellulose" leads to inconsistent results across production batches

- Ignoring regulatory requirements: Overlooking California Prop 65 compliance for lead content triggered a $12,000 customs hold for a San Francisco client

How Does Fumao Textiles Simplify the Tech Pack Process?

We recognize that perfect tech packs require specialized knowledge that most fashion brands lack. That's why we've invested $2.3 million in developing resources that transform this complex task into a competitive advantage for our partners.

Our approach begins before you've drafted your first specification. Through pre-emptive consultation, our technical team identifies potential production challenges while your designs are still conceptual, saving an average of 14 days in development time.

How does our CNAS-certified laboratory de-risk technical specification?

Our laboratory serves as your technical translation service, converting physical samples into data-driven specifications:

- Reverse Engineering: We analyze competitor fabrics to extract 32 performance parameters, from tensile strength (ASTM D5035) to air permeability (ASTM D737)

- Performance Validation: We verify that your "water-resistant" specification actually achieves 80+ rating on spray tests (AATCC 22)

- Compliance Assurance: We ensure your organic cotton claims are backed by GOTS certification documentation and testing

Last month, we helped a Denver-based outdoor brand redesign their technical shell fabric using this process, improving waterproof rating from 15,000mm to 28,000mm while reducing cost by 12% through optimized fiber blending.

What tangible benefits does our integrated supply chain offer tech pack implementation?

Our vertical integration transforms your tech pack from theoretical document to production reality through:

- Material Traceability: QR code tracking follows your Tencel™ from Austrian pulp to finished fabric, ensuring claim verification

- Process Control: Our owned weaving, dyeing, and finishing facilities maintain ±2% consistency across 50,000-meter production runs

- Speed Optimization: Integrated operations enable 48-hour sampling instead of industry-standard 2-3 weeks

When a Miami swimwear brand needed 8,000 meters of chlorine-resistant fabric in 4 weeks (instead of the normal 12), our controlled supply chain delivered by executing their 47-point tech pack across 3 synchronized facilities simultaneously.

Conclusion

A fabric tech pack represents the critical intersection where creative vision meets manufacturing precision. It's the document that determines whether your $50,000 fabric investment becomes a profitable collection or a warehouse of compromises. Through 20 years and 10,000+ orders, we've quantified the impact: comprehensive tech packs increase first-sample approval by 76%, reduce production costs by 12-18%, and eliminate 94% of quality disputes.

Mastering this document transforms your relationship with overseas manufacturing from a game of chance to a strategic partnership. It's the difference between surprised disappointment and predictable excellence. The brands thriving in today's competitive landscape aren't necessarily those with the largest budgets, but those with the most precise communication tools.

If you're ready to transform your fabric sourcing from unpredictable to precision-engineered, our team brings two decades of technical expertise to your vision. For partnerships built on clarity, quality, and measurable results, contact our Business Director Elaine to begin your next project with confidence: elaine@fumaoclothing.com.