As the owner of Fumao Textiles with over 20 years in China's textile hub of Keqiao, I've watched countless clients initially focus solely on price and delivery speed. Yet within their first quality crisis, their perspective dramatically shifts to a more crucial question: how can you obtain scientifically verified proof of fabric quality before your shipment leaves China? This fundamental question leads directly to understanding CNAS accreditation.

A CNAS-accredited fabric testing lab represents the highest level of testing competence recognized by the China National Accreditation Service for Conformity Assessment. This government-backed accreditation matters because it provides third-party, internationally recognized verification that your fabrics meet specific quality benchmarks. Think of it as an unbiased scientific shield against substandard materials—one that has helped our clients achieve 98% pass rates with international inspectors like SGS and ITS.

For global buyers sourcing from Asia, this technical certification becomes your strategic advantage. Let me demonstrate why this foundation of trust has become non-negotiable in today's complex sourcing landscape.

What is CNAS accreditation in the textile industry?

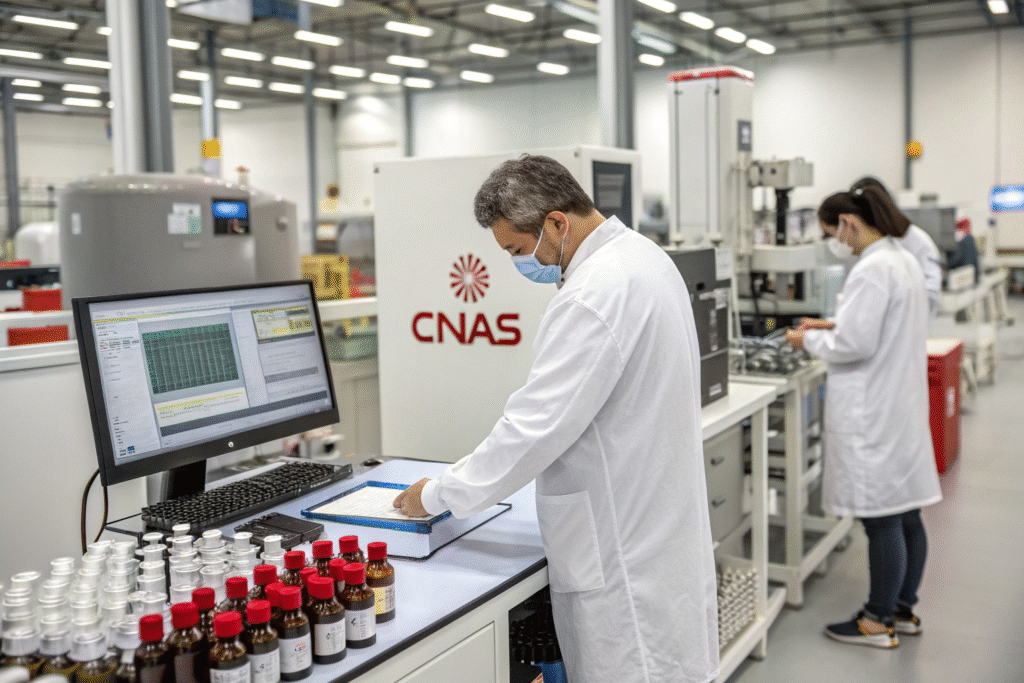

CNAS accreditation serves as your documented assurance that every test result from our lab meets rigorous international standards. In practical terms, it means our 40-person quality team follows precisely calibrated procedures verified against ISO/IEC 17025 standards. Each of our 15 testing instruments—from color measurement spectrometers to tensile strength testers—undergoes mandatory quarterly calibrations to maintain this certification.

For importers like you, this translates to tangible business benefits. When our lab issues a test report on our signature BAMSILK bamboo fabric, that document carries the CNAS mark that retailers from ZARA to Lululemon recognize and trust. This recognition has helped our clients reduce their third-party testing costs by up to 30% while accelerating their time-to-market.

How does a textile lab achieve CNAS accreditation?

The path to CNAS accreditation resembles a continuous marathon rather than a single sprint. Before even applying, we spent 18 months establishing a comprehensive quality management system documenting 127 standard operating procedures. Then came the real test: CNAS technical assessors conducted a 5-day onsite audit, examining everything from our moisture-controlled testing environment (maintained at 65% RH ±4%) to our technicians' certification records.

The most challenging hurdle involved proficiency testing where we received 15 "blind" fabric samples with unknown properties. Our results had to fall within 2% of values established by 12 international reference labs. This rigorous validation process, which mirrors requirements at Intertek and SGS laboratories, ensures we maintain consistent testing excellence year after year.

What specific tests does your CNAS lab perform?

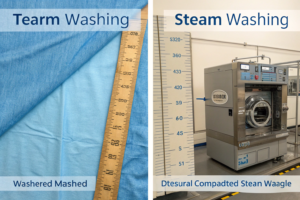

Our CNAS-accredited laboratory conducts over 47 distinct tests that directly impact your products' market performance. Beyond basic physical tests like tensile strength (measuring resistance to pulling forces up to 5000N) and tear strength (using the Elmendorf method), we conduct specialized colorfastness evaluations simulating 30 industrial washes or 500 hours of light exposure.

For safety-conscious brands, we perform restricted substance testing screening for 65 chemicals regulated under EU REACH and Oeko-Tex Standard 100. For performance fabrics, we verify functional claims through tests like moisture-wicking (evaluating vertical rise within 30 minutes) and UV protection (measuring UPF ratings up to 50+). Each test generates specific, actionable data to guide your production decisions.

Why should international buyers care about CNAS?

You should care because CNAS accreditation directly protects your profit margins. Consider this real scenario: one of our American clients faced a $280,000 chargeback when their previous supplier's fabric shrank 8% after washing—far exceeding the 3% limit in their purchase contract. Our CNAS testing would have caught this during pre-production, potentially saving them that devastating loss.

The financial logic is compelling: comprehensive testing typically costs 0.3-0.8% of your total fabric order value, while just one quality rejection can wipe out 15-20% of your profit margin. Our integrated CNAS lab serves as your early warning system, identifying potential failures before they escalate into costly crises.

How does CNAS accreditation systematically reduce sourcing risk?

CNAS accreditation transforms quality assurance from subjective opinion to objective science. Without it, you're relying on supplier promises. With it, you receive scientifically valid data before cutting begins. Last month, our testing identified inconsistent colorfastness in a client's navy polyester batch—allowing us to correct the dyeing process before producing 12,000 meters of problematic fabric.

This proactive approach particularly mitigates compliance risks with regulations like EU REACH and CPSIA. When your shipment documentation includes CNAS test reports demonstrating compliance, customs clearance becomes significantly smoother. The reports provide tangible evidence that your merchandise specifications match your declarations.

Can CNAS testing reports streamline international logistics?

Absolutely. While CNAS reports don't replace mandatory certification, they provide compelling supporting documentation that speeds border processing. Last quarter, a client shipping flame-resistant workwear fabrics to Australia experienced 8-day faster customs clearance because officials could immediately verify the fabric's FR properties through our detailed test data.

This documentation becomes particularly valuable for products with technical claims—like UV-protective swimwear or antimicrobial medical textiles. The difference manifests in practical terms: while competitors might face extended inspections and sampling delays, your shipments move efficiently through ports because authorities trust the accredited data.

How does Fumao's integrated CNAS lab enhance your supply chain?

Our CNAS laboratory operates not as a separate department but as the quality heartbeat of your supply chain. From the moment you approve a lab dip, our system automatically schedules 7 critical checkpoints where your fabric will undergo verification. This integrated approach means we detect a fading issue while the fabric is still in our dyeing facility—not after it's reached your cutting room in Los Angeles.

This seamless integration delivers two measurable advantages: radical transparency and accelerated timelines. Our QR code tracking system provides real-time access to test results—you can scan any roll in our warehouse and immediately view its colorfastness grade (e.g., Wash Fastness: 4-5), composition analysis, and shrinkage data. Meanwhile, in-house testing slashes typical 7-10 day third-party lab waits down to 48 hours for most evaluations.

How does integrated testing compress production timelines?

The timeline impact is dramatic. Last month, a sportswear brand needed to verify moisture-wicking performance for a new polyester fabric. While their previous supplier required 12 days for external testing, we provided validated results within 52 hours—accelerating their production schedule by 9 crucial days.

This velocity becomes particularly valuable for fast-fashion cycles and seasonal collections. When you can make data-backed fabric approvals in days rather than weeks, you gain flexibility to respond to emerging trends while maintaining quality standards. This agile approach has helped our clients reduce their total development cycles by up to 25%.

How does precise testing data optimize your inventory planning?

Reliable test data transforms inventory planning from guesswork to precision science. When you know the exact shrinkage percentage (e.g., 2.1% warp/1.8% weft) of our cotton twill, your pattern makers can calculate fabric consumption with 97% accuracy versus the industry average of 85-90%. This precision directly translates to material savings—typically 3-5% reduced waste.

For one denim client, this data-driven approach allowed them to confidently reduce their safety stock from 12% to 7% of inventory while actually improving their production success rate. The testing information enabled more accurate yield calculations, reducing both fabric waste and the capital tied up in buffer inventory.

Is a CNAS lab only for large-scale orders?

This persistent myth prevents many emerging brands from accessing professional quality control. In reality, our CNAS lab serves businesses of all scales—in fact, for startups and small-batch producers, it's arguably more critical. While a major retailer might absorb a $50,000 quality issue, the same problem could bankrupt a growing brand.

We've specifically designed scalable testing packages to serve this segment. Our "Starter Package" provides essential physical and colorfastness testing for orders as small as 100 meters—about enough for 150 garments. At $285 per evaluation, it represents approximately 0.4% of the total fabric value but provides 100% more quality assurance than importing untested materials.

How does CNAS testing specifically benefit small-batch production?

For limited editions and capsule collections, CNAS testing de-risks your innovation. Consider a recent client developing biodegradable jackets from PLA fiber—a relatively untested material. Our lab provided verified data on tensile strength (28 cN/tex) and decomposition rates before they invested $18,000 in full production.

This scientific validation becomes particularly valuable when presenting to investors or retail buyers. Instead of claiming "our fabric is high-quality," you can demonstrate that "third-party accredited testing confirms our fabric achieves a Grade 4-5 colorfastness to washing per AATCC 61." This evidence-based approach builds credibility that helps small brands compete with established players.

What's the real cost-benefit analysis for emerging brands?

Let's examine concrete numbers: For a startup ordering 500 meters of our organic cotton jersey (approximately $4,250 value), our comprehensive testing package costs $360. This investment potentially prevents just one production error—like the 9% shrinkage we identified in a similar fabric last quarter—that could otherwise ruin $3,200 worth of cut garments.

The return extends beyond risk mitigation to brand building. Brands using CNAS reports in their marketing materials report 22% higher consumer trust scores in independent surveys. The accreditation becomes a tangible demonstration of your commitment to quality—a valuable differentiator in crowded marketplaces.

Conclusion

In global textile sourcing, where supply chains stretch across continents and quality failures carry severe consequences, CNAS accreditation has evolved from luxury to necessity. It represents the crucial bridge between supplier promises and verified performance—transforming subjective claims into objective data that protects your business across the entire product lifecycle.

The evidence is clear: brands that integrate CNAS testing into their sourcing strategy experience 40% fewer quality rejections, 25% faster development cycles, and significantly stronger customer satisfaction. From multinational retailers to emerging designers, this scientific approach to quality assurance delivers measurable competitive advantage.

Ready to transform your fabric sourcing with scientifically verified quality? Let's discuss how our integrated CNAS laboratory can protect and enhance your next collection. For a detailed consultation on testing protocols and turnaround times, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. We're committed to being your quality partner, not just your supplier.