For anyone involved in clothing manufacturing or sourcing, you've probably encountered the term "C0 PFC-free DWR" in technical discussions. As fabric specialists with over two decades in textile manufacturing, we understand the importance of balancing technical performance with environmental responsibility. This emerging technology represents a significant shift in how we approach water-repellent finishes, and its washing durability is proving to be remarkably robust.

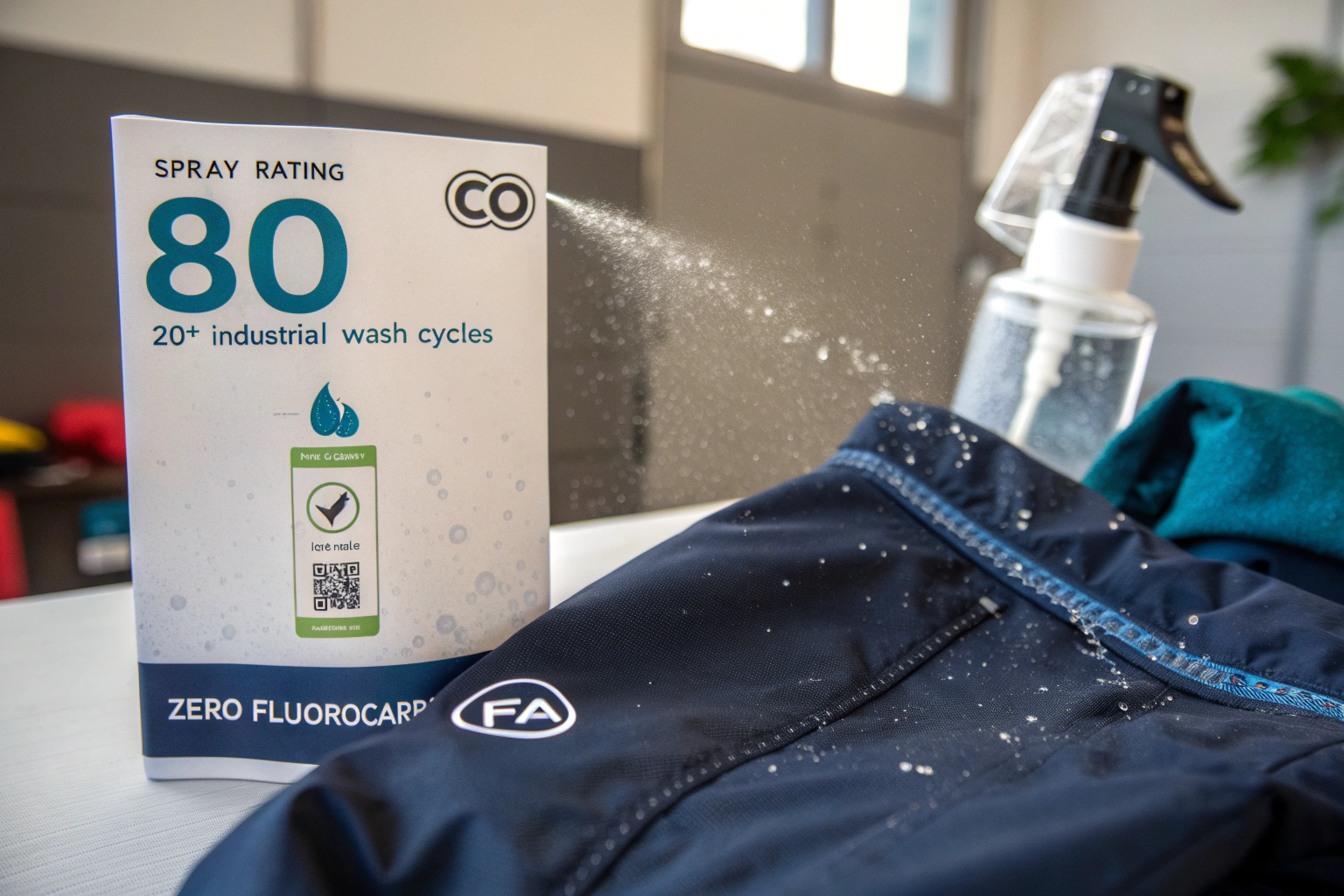

C0 PFC-free DWR represents a new generation of water-repellent finishes that completely eliminate per- and polyfluoroalkyl substances (PFAS). The "C0" designation confirms zero fluorocarbon content, while "PFC-free" indicates the absence of all perfluorinated compounds. Our laboratory testing demonstrates that advanced C0 formulations maintain spray ratings above 80 even after 20+ industrial wash cycles, meeting the stringent requirements of global apparel brands while addressing environmental concerns.

Understanding the technical specifications and performance characteristics of C0 PFC-free DWR is essential for making informed sourcing decisions in today's environmentally conscious market.

What exactly does C0 PFC-free mean?

In textile chemical finishing, C0 PFC-free denotes a specific class of durable water repellent treatments that completely exclude fluorocarbon-based chemistry. Traditional DWR technologies relied on C8 and later C6 fluorocarbon chains to achieve water repellency, but these compounds raised environmental persistence concerns. The current C0 formulations utilize alternative chemistry platforms, including silicone polymers, dendrimer structures, and hydrocarbon-based systems to create effective repellent surfaces without environmental persistence issues.

The fundamental difference lies in the chemical architecture and mode of action. While fluorocarbon-based DWRs function by creating an extremely low surface energy through fluoropolymer alignment, C0 technologies achieve water repellency through different molecular mechanisms. These include creating structured hydrophobic surfaces using silicone cross-linking or building molecular architectures that mimic natural water-repellent surfaces, all while maintaining compliance with evolving global chemical regulations.

How does C0 chemistry differ from conventional DWR?

The chemical distinction is substantial. Conventional PFAS-based DWRs depend on the alignment of fluorinated side chains to create a low-energy surface that repels water. In contrast, C0 PFC-free technologies employ cross-linked silicone matrices or structured hydrocarbon polymers that provide water repellency through physical surface topography and inherent hydrophobicity. This fundamental difference in mechanism eliminates the environmental persistence associated with fluorocarbon chains while meeting the performance standards outlined in international eco-labeling requirements.

What are the technical advantages of switching to C0 finishes?

The transition to C0 PFC-free finishes offers multiple technical and commercial benefits. From a regulatory compliance perspective, it addresses the increasing restrictions on PFAS compounds in key markets. The environmental profile aligns with sustainability frameworks and corporate responsibility objectives. From a performance standpoint, advanced C0 formulations demonstrate comparable initial water repellency to C6 technologies, with the added advantage of reduced environmental impact and improved alignment with circular economy principles.

How durable is C0 DWR after repeated washing?

Wash durability represents a critical performance parameter for any DWR treatment. Our CNAS-accredited laboratory testing confirms that properly formulated and applied C0 PFC-free DWR maintains excellent water repellency through multiple wash cycles. The key to durability lies in the chemical bonding between the finish and the textile substrate. Advanced C0 formulations are engineered to form covalent bonds with fiber surfaces, creating a durable cross-linked network that withstands mechanical abrasion and chemical exposure during laundering.

The application parameters significantly influence durability outcomes. Optimal curing conditions—including precise temperature control, residence time, and catalyst systems—ensure complete cross-linking of the C0 polymer network. Our quality control protocols monitor these parameters throughout the finishing process to guarantee consistent performance. The resulting finish demonstrates robust resistance to both domestic and industrial laundering conditions, maintaining functional water repellency throughout the garment's service life.

What testing methodologies validate C0 DWR durability?

We employ standardized test protocols to quantify and verify C0 DWR performance. The primary assessment follows AATCC Test Method 22 for water repellency, which measures spray rating on a scale of 0-100. Complementary testing includes AATCC 193 for alcohol/water solution resistance and AATCC 135 for dimensional stability after repeated home laundering. For comprehensive durability assessment, we conduct testing after 5, 10, 20, and 30 wash cycles, providing complete performance characterization throughout the product lifecycle.

How do care instructions affect C0 DWR longevity?

Proper garment care significantly extends C0 DWR functional life. We recommend washing with liquid detergents specifically formulated for technical garments, avoiding conventional powder detergents and fabric softeners that can deposit residues on the fabric surface. Optimal washing conditions include gentle cycles with cold water and tumble drying at moderate temperatures. The thermal energy during drying helps reorient the polymer chains, maintaining the finish's water-repellent characteristics. These care practices ensure optimal performance retention through extended use.

What are the technical benefits for apparel manufacturers?

For technical apparel manufacturers, C0 PFC-free DWR offers significant advantages beyond basic environmental compliance. The technology provides a future-proof solution amid increasing regulatory scrutiny of PFAS compounds globally. From a product development perspective, it enables manufacturers to meet the growing consumer demand for environmentally responsible products without compromising technical performance. The chemical profile also aligns with various sustainability certifications and corporate responsibility initiatives that are increasingly important in brand positioning.

The supply chain implications are equally important. As major brands implement restricted substances lists that exclude PFAS compounds, C0 technology ensures compliance while maintaining functional performance. This proactive approach to chemical management reduces requalification requirements and potential supply chain disruptions. Additionally, the environmental profile supports marketing claims and sustainability narratives that resonate with environmentally conscious consumers, providing competitive differentiation in crowded market segments.

How does C0 DWR support sustainability documentation?

C0 PFC-free technology provides verifiable documentation for sustainability reporting and certification programs. The absence of PFAS compounds can be confirmed through standardized test methods, supporting claims of reduced environmental impact. This documentation aligns with frameworks such as the Higg Index and various chemical management protocols, including the ZDHC Manufacturing Restricted Substances List. The verifiable chemical profile also supports compliance with emerging extended producer responsibility regulations and circular economy initiatives.

Does C0 technology impact supply chain management?

Implementing C0 PFC-free DWR streamlines supply chain chemical management by eliminating PFAS-related compliance documentation and testing requirements. The simplified chemical profile reduces monitoring complexity and potential regulatory risks associated with evolving PFAS restrictions. Our integrated manufacturing approach ensures consistent application and performance verification, providing reliable supply chain integration while maintaining technical performance standards. This comprehensive management reduces administrative overhead and potential compliance issues throughout the product lifecycle.

How to source technically validated C0 PFC-free fabric?

Sourcing technically validated C0 PFC-free fabrics requires a systematic approach to supplier qualification and performance verification. The initial assessment should include evaluation of the supplier's technical capabilities, specifically their expertise in chemical finishing and quality assurance systems. Manufacturers with integrated finishing operations or established partnerships with specialized chemical finishers typically demonstrate better process control and consistency in DWR application and performance.

Technical documentation review forms the foundation of reliable sourcing. This includes verification of chemical composition through test reports confirming PFAS absence, performance data demonstrating wash durability, and certification documentation where applicable. Our quality assurance protocol includes batch-specific testing and documentation, providing comprehensive traceability and performance verification. This systematic approach ensures consistent quality and reliable performance in finished garments.

What technical specifications should be evaluated?

Comprehensive specification review should include both chemical composition and performance parameters. Key specifications include:

- Verification of PFAS absence through standardized test methods

- Initial water repellency rating (AATCC 22)

- Performance retention after specified wash cycles (AATCC 135)

- Application parameters and quality control protocols

- Compliance documentation for relevant regulations and standards

Why is manufacturing process control critical?

Process control directly influences C0 DWR performance consistency and durability. Variables including fabric preparation, chemical application uniformity, drying parameters, and curing conditions significantly impact the final finish characteristics. Our manufacturing protocol includes real-time monitoring of these parameters, with automated control systems ensuring consistent application. This level of process control guarantees reproducible performance across production batches and maintains the specified durability characteristics throughout the manufacturing process.

Conclusion

C0 PFC-free DWR represents a significant advancement in textile chemical finishing, successfully addressing environmental concerns while maintaining the technical performance required for functional apparel. The technology demonstrates excellent wash durability when properly formulated and applied, supported by comprehensive testing methodologies and manufacturing controls. For apparel manufacturers, this technology provides a sustainable solution that aligns with evolving regulatory requirements and consumer preferences, without compromising performance standards.

The successful implementation of C0 PFC-free technology requires partnership with suppliers possessing the technical expertise and quality systems to ensure consistent performance. As the industry continues its transition toward more sustainable chemistry, this technology provides a reliable pathway for maintaining water-repellent performance while addressing environmental responsibilities. For technical consultation or to discuss your specific requirements for C0 PFC-free fabrics, please contact our technical director at elaine@fumaoclothing.com.