As a fabric manufacturer with over twenty years of experience in China's textile industry, I regularly advise international clients on this important question. Choosing the right printing method for polyester affects cost, quality, and how the final product looks. Many buyers find this decision challenging when trying to balance technical needs with budget limits.

The best printing method depends on what you need for your specific product. Sublimation printing works better for detailed, colorful designs on light polyester fabrics. Disperse dye printing is better for solid colors on dark polyester fabrics that need to stand up to repeated washing. Both methods use the same basic dyes but apply them in different ways.

Knowing the difference helps you make better decisions. It ensures your fabric meets quality standards and satisfies your customers. Let me explain the key points to help you choose wisely for your next order.

What is the basic difference between the two methods?

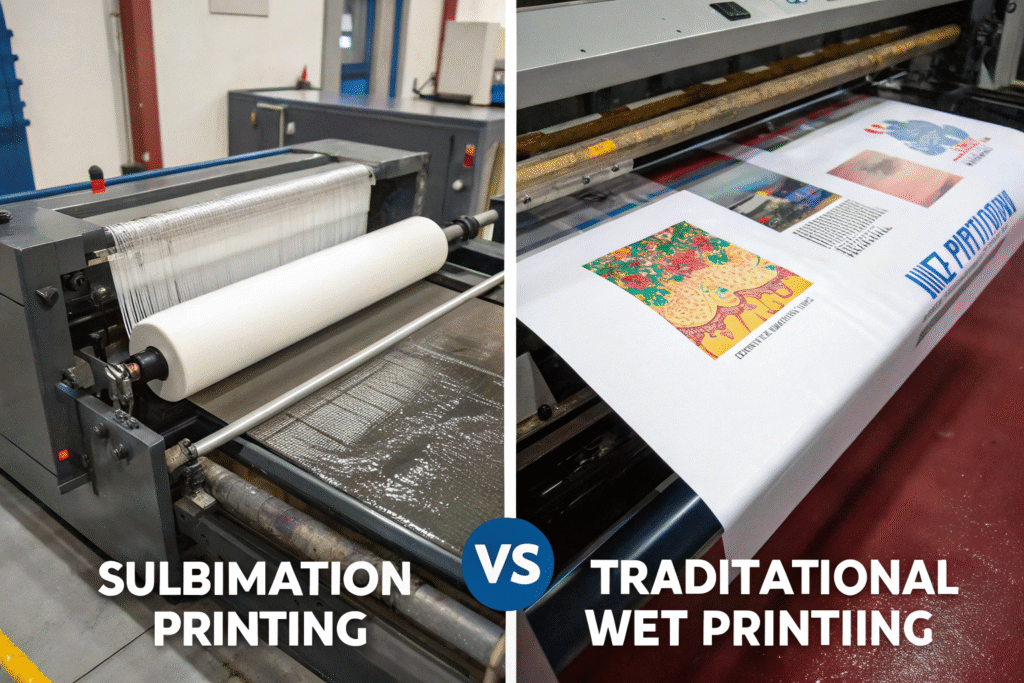

The main difference is in how the dye is applied and how it sticks to the fabric. Disperse dye printing puts dye paste directly on the fabric, then uses heat to set it. Sublimation printing first puts the design on special paper, then uses heat and pressure to transfer it to fabric, turning the dye from solid to gas in the process.

Disperse dye printing is a wet process. The dye paste is pushed through screens onto the fabric. Then the fabric goes through heat treatment to fix the dye into the fibers. This method works particularly well for printing on dark polyester fabrics.

Sublimation printing is a dry transfer process. We print the design first on special paper using liquid dyes. Then we use a heat press to transfer the design to fabric. The heat turns the dye into gas that penetrates the polyester fibers and becomes permanent when it cools. This method is perfect for all-over patterns used in sportswear and flags.

How does the dye stay in the fabric?

The way the dye bonds with the fabric affects how well the color holds up over time. Sublimation printing makes the dye part of the fiber itself. The dye gas goes deep into the polyester fibers and locks in place. This creates a permanent bond that won't peel or crack. That's why it's good for sportswear that needs frequent washing.

Disperse dye printing also holds up well when done properly. The heat treatment helps the dye work into the fibers. However, more dye stays near the surface compared to sublimation. This can make it more likely to fade with rough use and washing over time. Proper after-washing is important to remove any loose dye and ensure good color fastness.

Which method gives better colors and details?

Sublimation printing generally offers brighter colors and sharper details for complex designs. Because the design is first printed on paper, it can achieve high precision using modern digital printers. The transfer process allows for detailed patterns and realistic images. This makes it the best choice for fashion items with complicated graphics.

Disperse dye printing, usually done with screens, has some limits in color variety and fine details. Each color needs a separate screen, which adds cost and limits how many colors you can use. However, for solid colors or simple patterns on dark fabrics, it creates strong, opaque colors that sublimation can't match on dark materials. New digital disperse printing methods are improving these capabilities.

How do costs compare for large orders?

For big orders, disperse dye printing usually costs less per meter. Traditional screen printing for disperse dyes has high setup costs for making screens. But once the screens are made, the cost per meter goes down significantly for long runs. The printing process itself is very fast for repeating patterns on large fabric amounts.

Sublimation printing has lower setup costs, especially with digital methods. There are no screens to make. This works well for small batches and custom orders. However, the cost per meter can be higher for big orders because of the paper needed and the two-step process. The speed of the heat press can also limit production for very large quantities, though newer machines are faster.

What about costs for samples and small orders?

For samples and small runs, sublimation is usually cheaper and faster. Without screen costs, you can print small amounts with complex designs without high setup fees. This matches our company's ability to make samples quickly. We can provide samples within 48 hours, which helps brands test new designs.

Disperse dye sampling can be expensive and slow for small quantities because of screen costs. But for very large orders where the screen cost is spread over many meters, it becomes very cost-effective. We help clients choose based on their order size. If you're a small business or online store with changing needs, sublimation offers more flexibility.

When does each method become more cost-effective?

The cost comparison depends on how many colors you need and how much fabric you're printing. Here's a simple cost comparison:

| Order Size | Disperse Dye | Sublimation |

|---|---|---|

| 100 meters | High cost per meter | Low cost per meter |

| 1,000 meters | Medium cost per meter | Medium cost per meter |

| 10,000 meters | Low cost per meter | Higher cost per meter |

For orders over 5,000 meters with simple designs, disperse dye printing usually costs less. For complicated, multi-color designs on smaller runs, sublimation is more economical. Our flexible production system can handle both methods, ensuring you get the best price for any quantity.

Which method is better for the environment?

Both methods have environmental impacts, but improvements are being made. Sublimation printing uses less water than traditional wet printing. However, it uses transfer paper that creates waste. The energy needed for heat presses is also a consideration.

Disperse dye printing uses more water because it's a wet process. It needs water for the dye paste and for washing after printing. This creates wastewater that needs treatment. Our partner factories use modern water treatment systems to reduce this impact. We also use eco-friendly dyes that meet international standards.

What certifications should I look for?

For both methods, certifications help ensure environmental and safety standards are met. The Global Organic Textile Standard (GOTS) covers processing chemicals. Oeko-Tex Standard 100 certifies that textiles don't contain harmful substances. Our certified lab tests for these standards, giving clients confidence in our products.

The fabric itself also matters for sustainability. Using recycled polyester reduces the environmental impact of both printing methods. We offer recycled polyester fabrics that work well with both printing methods. This supports our company's commitment to environmental responsibility and meets the needs of eco-conscious brands.

How do they compare in waste and water use?

- Water Use: Disperse dye printing uses more water for washing. New equipment helps reduce this water use.

- Chemical Waste: Both processes use chemicals that need proper handling. We make sure our partner factories manage chemicals responsibly.

- Solid Waste: Sublimation creates used paper waste. We're working on ways to recycle this paper.

At Fumao, we help clients choose the most sustainable option for their project, using our experience with eco-friendly materials.

How do I choose based on what I'm making?

Your choice should match your product's purpose. For athletic wear, swimwear, and flags, sublimation is usually better. It keeps the fabric stretchy and breathable while allowing colorful all-over designs. The dye doesn't sit on the surface, so it doesn't affect how the fabric feels or handles moisture, which is important for sportswear.

For home textiles like curtains and furniture fabric, and for dark-colored uniforms, disperse dye printing works well. It creates strong, solid colors on dark polyester that sublimation can't match. The print can also make the fabric feel heavier if needed, which is good for curtains and upholstery.

What are the fabric requirements?

Both methods work only with synthetic fibers like polyester. The dyes need polyester's chemical structure to bond properly. They don't work well with natural fibers like cotton or wool.

For polyester-cotton blends, the results differ. Sublimation only dyes the polyester part, leaving the cotton white. This gives a faded, vintage look. Disperse dye printing can be used on blends, but needs special care to avoid staining the cotton. For pure polyester, both methods work well. We help clients pick the right base fabric from our wide selection to match their printing choice.

Which is better for complicated designs and samples?

For detailed, photographic designs and quick samples, sublimation is unbeatable. The digital process allows unlimited colors and details without extra cost. This is perfect for clients who need fast development. We can make samples within 48 hours for quick market testing.

Disperse dye printing is better for simple, repeating patterns and solid colors, especially on dark fabrics. While digital disperse printing is improving, it's not as good as sublimation for complex artwork. For brands focused on bold designs or uniform stripes, disperse dye is a reliable and cost-effective solution.

Conclusion

Choosing between disperse dye and sublimation printing for polyester isn't about finding one best method. It's about matching the method to your product's specific needs. Consider your design complexity, order size, color requirements, and how the fabric will be used. Sublimation works best for bright, detailed designs on light fabrics, while disperse dye works best for solid colors on dark fabrics.

At Fumao Textiles International, we work with you to find the best solutions. Our team of experienced professionals helps you through these technical choices. We manage the entire process from weaving to finishing. This ensures quality, fast production, and good prices, while handling shipping and customs for our international clients.

Ready to make your next clothing order with the perfect print? Let's talk about your project. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to start with a professional fabric solution made for you.