Choosing the right fabric is crucial for polo shirt production. Two main options dominate the market. These are traditional cotton pique and technical polyester dry-fit. Each fabric offers distinct advantages. Your selection will significantly impact the final product's performance.

The optimal choice depends on your target market and performance requirements. Cotton pique delivers classic comfort and premium aesthetics. Polyester dry-fit excels in moisture management and durability. Many manufacturers now combine both materials. This approach creates hybrid fabrics with balanced characteristics.

This comprehensive analysis examines four key aspects. We evaluate comfort properties and durability factors. We assess moisture management capabilities and cost considerations. This information will guide your fabric selection process.

What Are the Comfort and Texture Differences?

Comfort represents a primary concern for consumers. The fabric's hand feel determines initial wearing experience. Natural and synthetic fibers provide distinct tactile sensations.

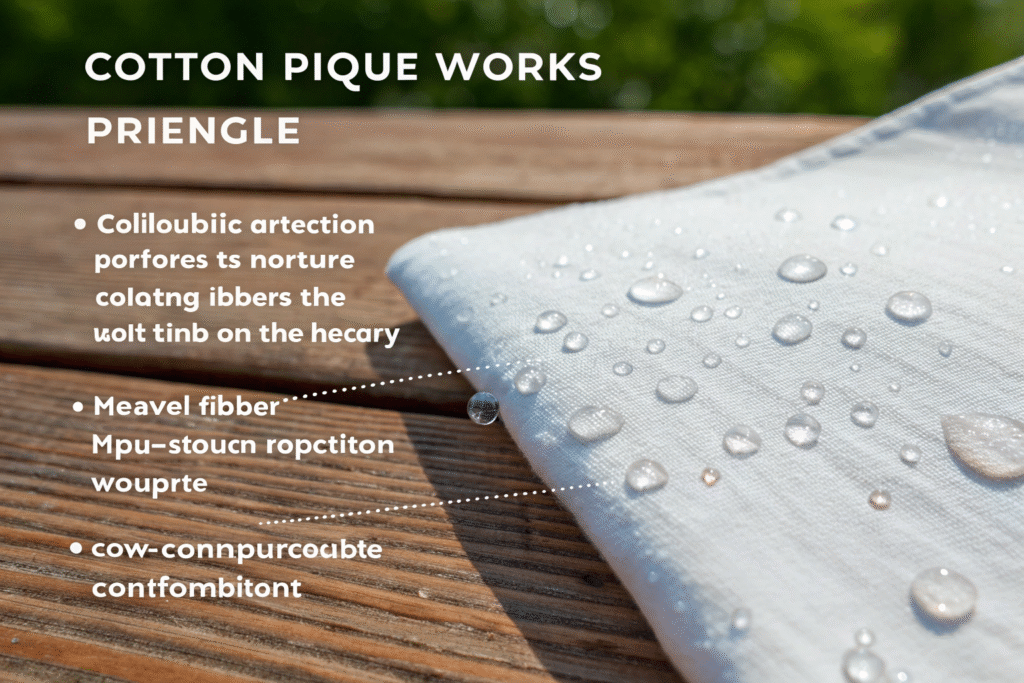

Cotton pique features a soft, textured surface. Its unique weaving pattern creates raised geometric structures. This construction promotes air circulation through the fabric. Natural cotton fibers offer gentle skin contact. They rarely cause allergic reactions. The material conveys substantial quality perception. It remains preferred for business casual applications.

Polyester dry-fit presents smooth, technical characteristics. Its engineered surface facilitates rapid moisture transport. The fabric feels lightweight against the skin. It often provides cooling sensations during physical activity. Some users perceive it as less plush than natural alternatives. Its aesthetic aligns with athletic wear requirements.

How Does Breathability Compare Between These Fabrics?

Breathability indicates air permeability through textile structures. Effective breathability maintains thermal comfort during wear.

Cotton pique demonstrates excellent breathability characteristics. Its natural fiber composition and porous structure enable air movement. This makes it suitable for office environments and casual settings. The fabric supports natural temperature regulation. However, moisture absorption reduces its breathability performance. Damp fabric tends to cling uncomfortably to skin.

Polyester dry-fit employs advanced construction techniques. Micro-porous knitting technologies enhance ventilation properties. This design maximizes airflow during athletic activities. The fabric maintains consistent breathability in humid conditions. It outperforms cotton in high-intensity usage scenarios.

Which Fabric Provides Superior Durability?

Durability affects product longevity and customer satisfaction. Fiber composition largely determines endurance characteristics.

Polyester dry-fit offers exceptional durability. Synthetic fibers resist abrasion and mechanical stress. The fabric maintains dimensional stability through repeated washing. Solution-dyed colors demonstrate fade resistance. These properties make it ideal for performance apparel and uniform applications.

Cotton pique provides adequate durability for regular use. Natural fibers may experience gradual degradation. Proper care minimizes shrinkage and pilling issues. High-quality cotton constructions ensure respectable lifespan. The fabric suits premium casual wear markets perfectly.

How Do These Fabrics Manage Moisture?

Moisture management capabilities differentiate these materials significantly. Performance varies based on fiber chemistry and fabric engineering.

Polyester dry-fit employs advanced wicking mechanisms. Hydrophobic fiber properties repel moisture absorption. Capillary action moves liquid to the fabric surface. Rapid evaporation keeps wearers dry during exertion. This makes it optimal for athletic and outdoor applications.

Cotton pique operates through absorption principles. Cellulosic fibers naturally attract and retain moisture. This creates cooling effects in dry conditions. However, saturated fabric feels heavy and uncomfortable. The material suits low-activity scenarios better.

What Is the Scientific Basis for Moisture Wicking?

Moisture wicking relies on fundamental physical principles. Capillary action drives liquid transport through micro-channels.

Polyester fibers feature engineered surface geometries. Microscopic grooves create directional moisture movement. This process occurs independently of absorption. Many technical textiles utilize these physical principles. The system maintains comfort during perspiration.

Cotton lacks inherent wicking architecture. Its fibers absorb moisture through hydrogen bonding. This hydration process saturates fiber structures. Surface treatments can impart temporary wicking properties. However, the fundamental mechanism remains absorption-based.

Which Fabric Demonstrates Faster Drying Times?

Drying speed influences garment convenience and functionality. evaporation rates determine time to dryness.

Polyester dry-fit exhibits remarkably fast drying characteristics. Surface moisture evaporates quickly through air exposure. Body heat accelerates this process during wear. This enables quick turnaround between uses. The property benefits travelers and athletes significantly.

Cotton pique requires extended drying periods. Internal moisture must migrate to the surface first. Evaporation then proceeds relatively slowly. Machine drying accelerates the process but risks dimensional changes. Polyester clearly outperforms in drying speed metrics.

What Are the Cost Considerations for Bulk Orders?

Production costs directly impact business profitability. Fabric selection influences final product pricing structures.

Polyester dry-fit typically offers cost advantages for volume production. Petroleum-derived raw materials maintain stable pricing. Manufacturing processes achieve high efficiency levels. This creates favorable economics for large uniform orders and sportswear lines.

Cotton pique commands higher price points. Agricultural processes involve substantial resource inputs. Market fluctuations affect raw material costs. Specialized weaving adds manufacturing expenses. The premium positioning justifies increased costs.

How Do Material Costs Affect Final Pricing?

Fabric costs constitute significant portions of total production expenses. Material selection directly influences retail pricing strategies.

Polyester's economical pricing enables competitive retail positioning. Brands can achieve healthier profit margins. This advantage supports market share growth. Cost-conscious consumers appreciate the value proposition.

Cotton's premium pricing necessitates higher retail tags. Customers expect quality commensurate with price points. Marketing should emphasize natural origins and comfort benefits. The strategy targets discerning consumer segments effectively.

What Long-Term Value Do These Fabrics Provide?

Value assessment extends beyond initial purchase price. Durability and perception influence long-term satisfaction.

Cotton pique delivers enduring style and comfort. Timeless aesthetics support extended wardrobe life. Consumers perceive natural materials as premium choices. This enhances brand reputation and loyalty.

Polyester dry-fit offers functional longevity. Its resilience withstands rigorous use cycles. Replacement frequency decreases for organizational purchases. The economic benefit accumulates over time.

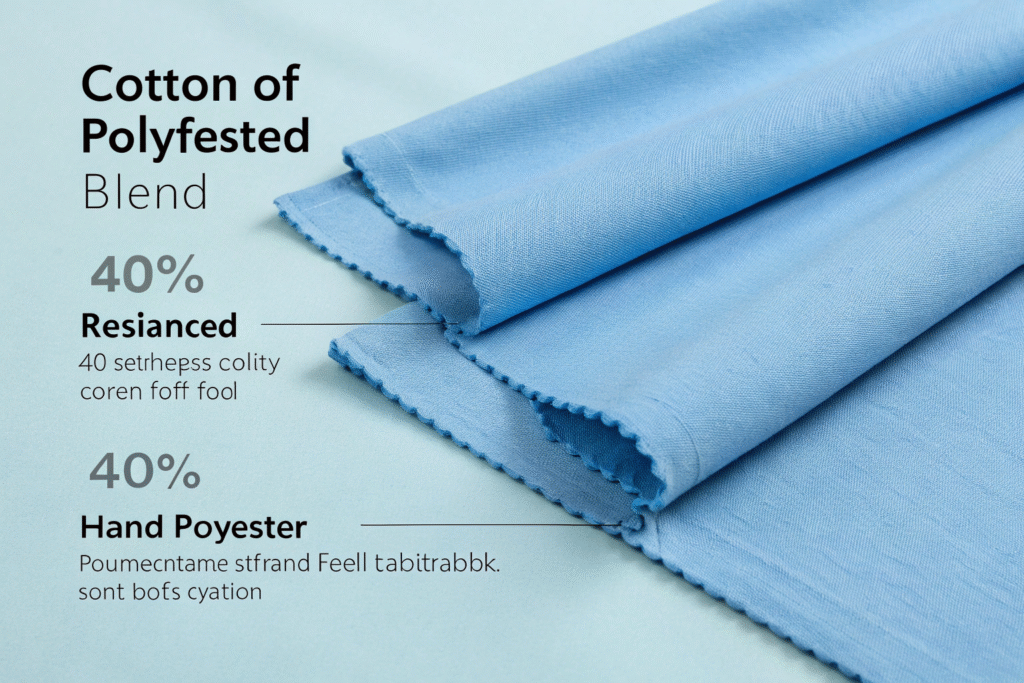

Are Blended Fabrics the Optimal Solution?

Hybrid fabrics combine complementary properties effectively. Blending technologies create versatile textile solutions.

Cotton-polyester blends balance competing attributes successfully. Common ratios include 60% cotton and 40% polyester. This combination preserves cotton's soft hand feel. It incorporates polyester's durability and wicking capabilities. The resulting fabric serves diverse application needs.

Advanced construction methods enable further optimization. Face and back surfaces can utilize different fiber compositions. Our custom development team specializes in engineered solutions. We create tailored fabrics for specific market requirements.

What Advantages Do Blended Fabrics Offer?

Blended textiles deliver multiple practical benefits. They overcome limitations of single-fiber constructions.

Key advantages include enhanced wrinkle resistance and reduced shrinkage rates. Blended fabrics demonstrate improved drying performance compared to pure cotton. They retain more natural softness than 100% polyester. The combined strength increases durability substantially. These factors make blends practical choices for various applications.

How Can Fumao Textiles Develop Custom Blends?

Our company provides comprehensive fabric engineering services. We create customized solutions for unique requirements.

The process begins with detailed requirement analysis. Our technical team examines performance needs and market positioning. Laboratory testing evaluates various fiber combinations. We incorporate sustainable materials when requested. Sample production ensures quality before bulk manufacturing. This method guarantees optimal results for clients.

Conclusion

Fabric selection requires careful consideration of multiple factors. Cotton pique satisfies traditional comfort expectations. Polyester dry-fit meets technical performance demands. Blended fabrics offer balanced solutions for diverse needs.

Our company possesses extensive manufacturing expertise. We control complete production processes from fiber to finished fabric. Global clients benefit from our supply chain advantages. Quality assurance systems maintain consistent standards. We support brands worldwide with reliable textile solutions.

Contact our Business Director Elaine for personalized assistance. Discuss your specific polo shirt fabric requirements. She provides expert guidance and competitive quotations. Reach her directly at elaine@fumaoclothing.com. We welcome opportunities to support your business growth.