Have you ever sat on a chair that felt cool in summer? Have you worn shoes that cushioned well without weight? You might have experienced spacer fabric. Our company makes fabrics in Keqiao, China. We have worked with textiles for twenty years. Many international clients ask about this material. They want to know its structure and benefits. Understanding spacer fabric is essential for modern sourcing.

Spacer fabric is a three-dimensional knitted material. It has two separate outer layers. These layers connect by an inner layer of monofilament yarns. This structure creates breathable cushioning. It resists compression well. People use it where airflow and moisture management matter. Common uses include athletic footwear and automotive seating. It also appears in medical mattresses and technical apparel. The construction offers comfort and performance.

This article explores spacer fabric in detail. We examine its construction and properties. We study its various applications. You will learn why this material matters. You will see how it adds value to products.

What are the key properties of spacer fabric?

Spacer fabric creates more than bulk. It engineers specific performance traits. Clients often ask about its advantages. We start with basic properties. These traits come from three-dimensional construction. Our factories control the knitting process precisely. Knowing these properties shows the material's potential.

Spacer fabric has several key properties. It offers superior breathability. It resists compression effectively. It manages moisture well. It has a high strength-to-weight ratio. An air gap exists between the two fabric layers. This gap allows constant airflow. The inner monofilament layer provides durable cushioning. It springs back after pressure releases. These traits make it versatile for technical uses.

How does the 3D structure enhance breathability?

Breathability comes from the fabric's architecture. Two outer layers use fine yarns. They create smooth surfaces. Spacer yarns connect these layers. The yarns form thousands of tiny air channels. This works like a miniature ventilation system. Air circulates freely between the layers. Heat and vapor move away from surfaces. This beats closed-cell foams. Those foams trap heat and moisture. Automotive seating needs this feature. Athletic footwear benefits greatly. Users experience cooler, drier comfort.

Why is spacer fabric so durable and resilient?

Durability comes from materials and construction. Monofilaments use robust materials. Polyester and nylon are common choices. These filaments withstand repeated compression. They bend under pressure. They distribute force throughout the structure. They spring back when pressure stops. This is high compression resilience. Our CNAS-certified lab tests this property. We ensure fabrics keep thickness and cushioning. Polyurethane foams often flatten permanently. Spacer fabric works well in medical mattresses. It serves industrial seating perfectly. Product longevity matters greatly in these applications.

Where is spacer fabric commonly used?

Spacer fabric applications keep expanding. Our company develops custom solutions for various industries. Buyers consider both quality and price. Diverse applications show the material's value. It solves multiple design challenges. It addresses comfort and safety needs.

Spacer fabric serves several sectors. It prioritizes ergonomic comfort and technical performance. You find it in running shoe midsoles. Office chair lumbar support uses it. Luxury car seats incorporate it. Hospital beds need its anti-decubitus surface. New areas include protective sportswear. Backpack straps use it too. Architectural panels experiment with it. This shows remarkable versatility.

How is 3D mesh revolutionizing the footwear industry?

Footwear relies heavily on spacer fabric. Manufacturers use it in shoe tongues and insoles. They place it in collars too. It reduces weight significantly. It enhances breathability and cushioning. Traditional padded tongues trap heat. They add unnecessary bulk. Spacer fabric tongues provide structure and comfort. Air circulates around the instep. Insoles gain moisture-wicking capability. They offer cushioned platforms. Major brands choose it for performance lines. The fabric heat-molds into complex shapes. Designers create seamless components. This streamlines footwear manufacturing. It reduces material waste.

What makes spacer fabric ideal for automotive and furniture seating?

Automotive and furniture industries seek lasting comfort. They value aesthetic appeal. Spacer fabric enables seat ventilation systems. It forms lumbar support panels. It replaces conventional foam. Car seats use it with built-in fans. Fans push cool air through the seat. This solves the sticky back problem. Office and home furniture need supportive surfaces. Spacer fabric prevents overheating. It resists sagging and deformation. Foams often fail here. Customer satisfaction increases. Warranty claims decrease. We supply automotive supply chain partners. They appreciate our consistent quality. They value our colorfastness testing.

How is spacer fabric manufactured?

Manufacturing knowledge helps buyers appreciate value. Our company controls the entire supply chain. We manage knitting, dyeing, and finishing. This ensures quality and fast production. We offer customizations others cannot. The process blends technology and expertise.

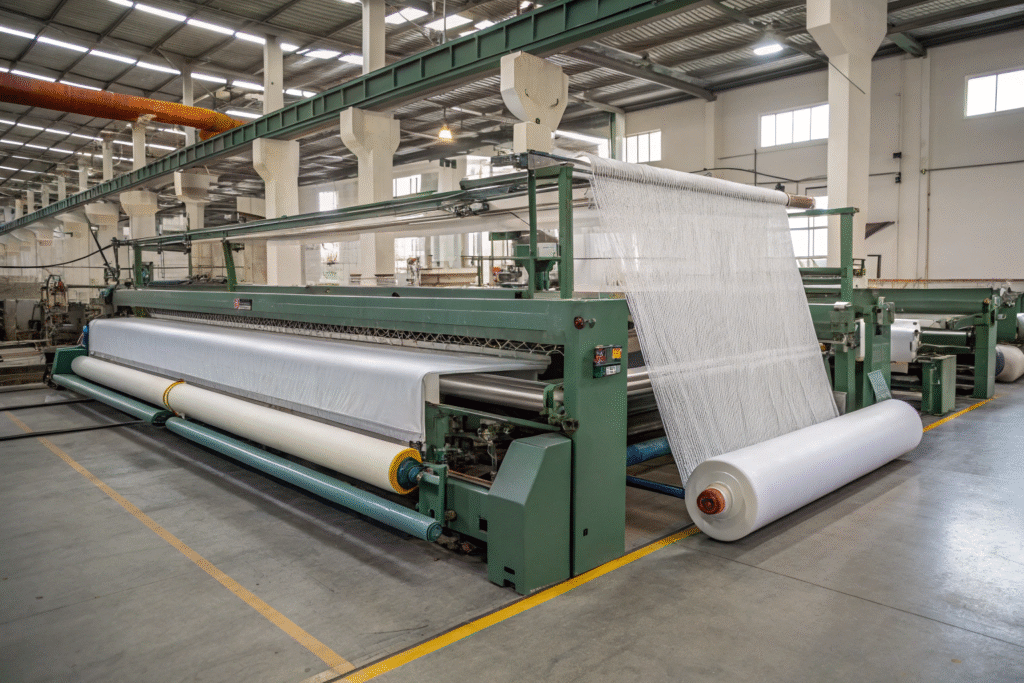

Spacer fabric needs special manufacturing. Warp knitting machines create it. Double-needle bar raschel machines are common. The process uses two yarn sets. One set makes the top and bottom layers. The other set forms the middle spacer. Machines interloop these yarns simultaneously. This builds the three-dimensional structure. Finishing processes follow knitting. Dyeing adds color. Coating adds function. Heat-setting stabilizes the fabric.

What is the role of warp knitting in creating 3D mesh?

Warp knitting is essential for spacer fabric. It differs from weft knitting. Weft knitting makes jersey fabrics. Warp knitting forms loops vertically. Double-needle bar machines have opposing needles. Outer layers form on these needle bars. Spacer yarns shuttle between them. This locks the layers together. The fabric becomes stable. It resists unraveling. Density and thickness are controllable. Machine programming allows precision. We make soft mesh for apparel. We make rigid mesh for structures. Our agile R&D uses this capability. We develop samples in forty-eight hours.

How do finishing processes like coating enhance functionality?

Unfinished spacer fabric has good properties. Finishing processes unlock more potential. We apply durable water repellent coating. This creates water resistance. Breathability remains high. Outdoor gear needs this combination. We use PU coating for stability. Lamination to other materials becomes easier. We add antimicrobial treatments. We include flame retardancy. We provide UV protection. Each finish suits specific applications. We test all finishes thoroughly. Our lab follows international standards. SGS and ITS certifications matter. We offer one-stop customization. This distinguishes us from traders.

Why should you choose Fumao for your spacer fabric needs?

Supplier choice involves multiple factors. Price is one consideration. Partnership and reliability matter more. We built our model for American clients. We address tariff and logistics concerns. We ensure quality control. We provide end-to-end service.

Fumao Textiles offers several advantages. We have vertical integration. We provide expert R&D support. We commit to sustainable innovation. Our spacer fabrics range from standard to high-performance. We enforce stringent quality control. We maintain financial stability. Our Keqiao location provides resource access. We handle small batches and large orders. We work efficiently and cost-effectively.

How do we ensure consistent quality and smooth logistics?

Quality and logistics connect closely. We start with our testing center. It has CNAS accreditation. We check every raw material batch. We test every finished fabric roll. We verify composition and colorfastness. We measure shrinkage and physical properties. This achieves a 98% client pass rate. Logistics uses Silk Road Keqiao initiatives. We partner with major shipping lines. We provide door-to-door service to the US. We handle documentation and packaging. We manage customs clearance. We give real-time tracking. Our financial partnerships secure cash flow. We get better raw material prices. We offer secure payment terms. L/C and T/T options protect both parties.

What are our competitive advantages in pricing and development?

Pricing advantages come from integration and scale. We control production stages directly. Our Keqiao location reduces intermediate costs. US tariffs affect some fabrics less. Our product classification is correct. Our sourcing strategies help. Development involves constant innovation. Twenty R&D experts work on new blends. We use recycled polyester. We choose organic cotton. We follow global sustainability trends. We reverse-engineer samples quickly. We create new designs from tech packs. We accelerate your time-to-market. Sustainable textiles get our focus. Agile innovation makes products market-leading.

Conclusion

Spacer fabric is an innovative textile. It combines comfort, durability, and breathability. Its three-dimensional structure serves many industries. Footwear and automotive applications are common. Medical and apparel uses grow steadily. Understanding this material improves sourcing decisions. It enhances final products significantly.

The right manufacturing partner unlocks full value. We invite you to try the Fumao difference. We help create high-quality products. We maintain cost-effectiveness. Your customers will appreciate the results. Contact our Business Director for specific needs. Elaine can discuss your requirements. Her email is elaine@fumaoclothing.com. She will send our latest spacer fabric catalog. We want to co-create value with you.