Many fabrics gain special properties through lamination. TPU lamination is a key process for performance textiles. As a fabric producer in China's Keqiao district, I often explain this technology. Buyers seek durable and waterproof materials. Understanding TPU lamination helps you make better sourcing decisions.

TPU lamination bonds a thermoplastic polyurethane film to fabric. This creates a composite material. The result is waterproof and windproof fabric. It also maintains breathability. You should use it for protective clothing and gear. Applications include outdoor apparel and medical wear.

Selecting the right fabric treatment matters. It affects product performance and customer satisfaction. Let me explain TPU lamination in simple terms. This knowledge will help your product development.

What is TPU Film Made Of?

TPU film is the core component. Its composition determines final fabric performance. Thermoplastic Polyurethane is a special polymer. It combines properties of hard plastics and soft rubber.

TPU contains both hard and soft segments. The hard parts provide strength. They resist abrasion and oils. The soft parts create flexibility. They allow stretching and bending. This combination is unique. It makes TPU ideal for technical textiles.

We use premium TPU films at Fumao Textiles. This ensures consistent quality. Your products will perform reliably.

How Does TPU Chemistry Affect Performance?

TPU resists many chemicals. It handles oils and greases well. This makes it suitable for workwear. It also works for medical applications.

TPU comes in different types. Polyester-based TPU resists oil better. Polyether-based TPU fights moisture better. Choose based on your needs.

What Are Key Physical Properties?

Good TPU film has strong tensile strength. It stretches well without breaking. It stays flexible in cold conditions. It withstands rubbing and scraping.

We test all these properties in our lab. Our fabrics meet international standards. You can trust their performance.

How is TPU Laminate Applied to Fabric?

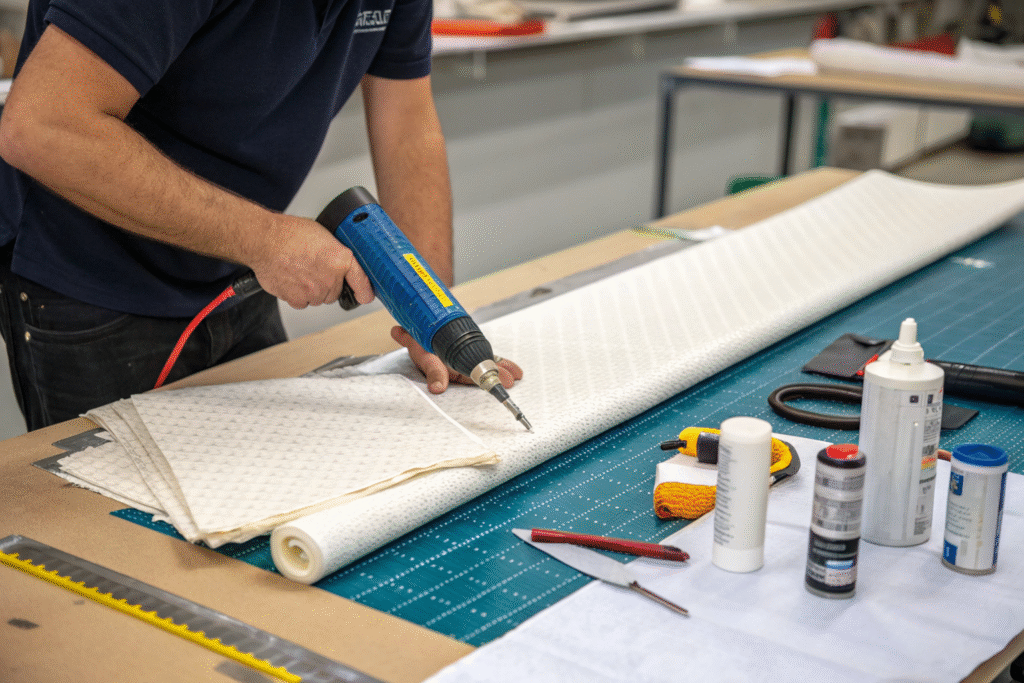

The process is called hot-melt lamination. It requires precision and expertise. We prepare the base fabric first. We clean and treat it for better adhesion.

TPU film passes through heated rollers. The heat makes it melt. We press the melted film onto fabric. It cools and forms a permanent bond.

This method doesn't use solvents. It is more environmentally friendly. It preserves fabric quality.

What Are Different Lamination Methods?

Hot-melt calendering is our main method. Flame lamination uses open flames. It can affect fabric feel. Adhesive lamination uses glue. It might reduce breathability.

We prefer hot-melt calendering. It gives the best results. It maintains fabric integrity.

How Do You Ensure Quality?

We control three main factors. Temperature must be precise. Pressure must be even. Speed must be consistent.

We conduct multiple tests. We check bond strength. We verify waterproof ratings. Our quality control is strict. It ensures customer satisfaction.

When Should I Choose TPU Lamination?

Choose TPU lamination for protective products. It creates true waterproof barriers. It blocks wind effectively. It allows moisture vapor to escape.

Use it for rainwear and ski jackets. It works for mountain sports apparel. It suits medical protective wear. It serves inflatable products well.

Is It Good for Lightweight Fabrics?

Yes, it works well with light materials. It adds function without much weight. This benefits packable outdoor gear. Think of lightweight rain jackets.

The laminate can be very thin. It doesn't need heavy adhesives. Your products stay light and comfortable.

How Does It Compare to Other Laminates?

TPU differs from PVC and PU. PVC is cheaper but less flexible. PU is softer but less durable. TPU offers the best balance.

Consider this comparison:

| Feature | TPU | PVC | PU |

|---|---|---|---|

| Flexibility | Excellent | Fair | Good |

| Durability | High | Medium | Medium |

| Eco-Friendliness | Good | Poor | Fair |

| Cost | Higher | Lower | Medium |

TPU is more sustainable. Some types can biodegrade. It represents a smarter long-term choice.

What Are the Pros and Cons of TPU Lamination?

TPU lamination has clear advantages. It creates durable fabrics. It provides waterproof protection. It allows breathability. It maintains flexibility. It enables strong seams.

However, consider the limitations too. It increases cost. It adds some weight. It affects fabric softness. It requires proper care.

What Are the Main Drawbacks?

Cost is the primary concern. TPU lamination is more expensive than basic treatments. It makes fabric heavier. It reduces softness somewhat.

Improper care causes problems. High heat can damage it. Harsh detergents aren't recommended.

How Sustainable Is It?

TPU is more eco-friendly than PVC. It contains no chlorine. It uses no phthalates. We now offer better options.

Recycled TPU is available. Bio-based TPU uses renewable materials. We invest in green technologies. Our partners appreciate this commitment.

Conclusion

TPU lamination transforms ordinary fabrics. It creates high-performance materials. Understanding this process helps your business. You can make better product decisions.

We at Fumao Textiles master this technology. We offer complete fabric solutions. Our experience spans twenty years. We ensure quality from start to finish.

Contact us for your next project. Reach our Business Director Elaine at elaine@fumaoclothing.com. Let's create outstanding products together.