Choosing the wrong fabric for your furniture can be a costly mistake. You invest in a beautiful sofa or chair, only to see it wear out and look old too soon. The key to avoiding this is understanding fabric durability. For anyone sourcing fabrics, especially for upholstery, knowing how to measure a fabric's ability to withstand wear is crucial. Two names always come up: the Martindale test and the Wyzenbeek test. But what are they, and which one should you trust for your next big order?

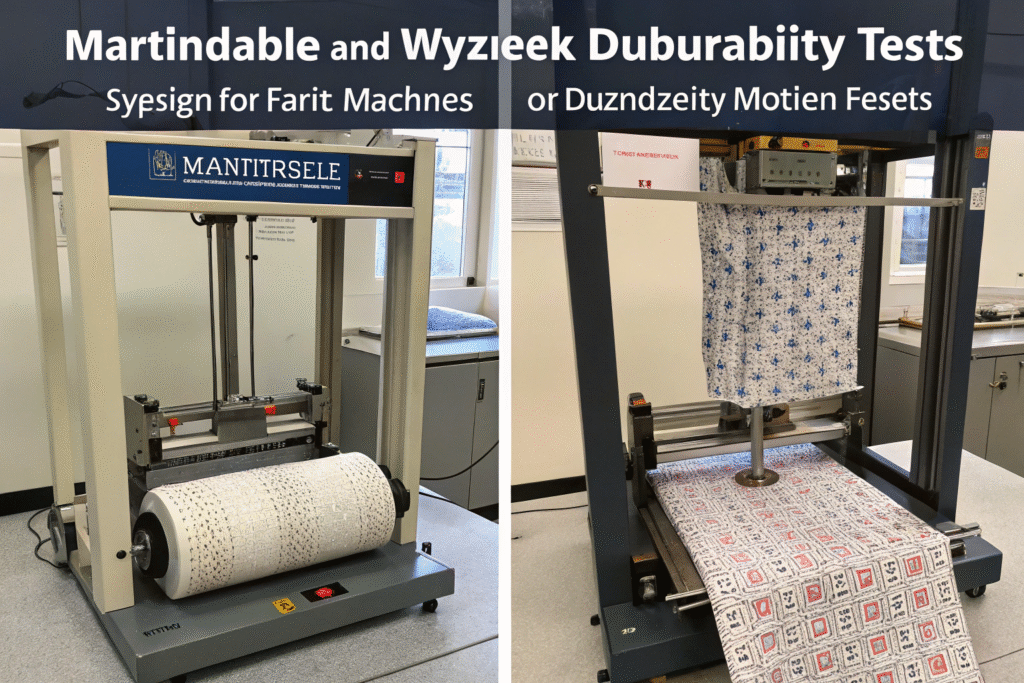

If you are buying fabrics for furniture, you need to know about abrasion resistance. The Martindale and Wyzenbeek tests are the two main methods used globally to measure how well a fabric will hold up to repeated use. While both tests aim to predict fabric longevity, they use different machines and motions. As a fabric supplier, we use these tests to ensure our materials meet the demands of your market and help you make informed decisions.

This guide will break down these two critical tests. We will explore how each test works, where they are used, and how to interpret the results. You will learn how we at Fumao Textiles apply this knowledge to deliver fabrics that are not only beautiful but also built to last. This will help you avoid costly returns and build a reputation for quality.

What is the difference between Martindale and Wyzenbeek tests?

When you hear about fabric durability, Martindale and Wyzenbeek are the standards. But they are not the same. The main difference lies in the motion. The Martindale test uses a figure-eight rubbing motion. The Wyzenbeek test uses a back-and-forth, linear motion. This fundamental difference means the tests can give different results for the same fabric. Knowing which test is relevant for your market is the first step in selecting the right material.

The core difference is the wear action. The Martindale test rubs the fabric in a gentle, continuous figure-eight pattern. The Wyzenbeek test uses a straight back-and-forth motion, much like a person sliding on a seat. Think of Martindale as multi-directional wear and Wyzenbeek as linear wear. This is why some fabrics perform better on one test than the other.

How does the testing motion affect the results?

The motion of the test directly impacts how the fabric fibers are stressed. The Martindale test's figure-eight motion applies abrasion from constantly changing angles. This can be more demanding on certain weaves. The Wyzenbeek test's straight-line motion is a more direct, repetitive action. For fabrics with a distinct pattern or nap, like velvet, the linear motion might cause more visible damage faster. This is why contract upholstery for high-traffic areas often references Martindale cycles, as it simulates multi-directional wear from varied use.

What do the fabric rub counts actually mean?

The "rub count" is the number of cycles a fabric can endure before showing significant wear. A higher number means better durability. However, these numbers are not interchangeable between the two tests. For example, 15,000 double rubs on a Wyzenbeek test is not the same as 15,000 cycles on a Martindale test. The Association for Contract Textiles (ACT) provides general guidelines, classifying fabrics for different uses. A fabric with 15,000 double rubs (Wyzenbeek) might be suitable for heavy residential use, while one with 30,000+ cycles (Martindale) is often specified for commercial settings.

Which abrasion test is more popular in the US market?

If you are selling to the US, you need to know the local standards. The Wyzenbeek test has been the traditional and most widely accepted method in the United States for decades. Many US manufacturers and brands specify their durability requirements based on Wyzenbeek double rubs. It is the language spoken by American furniture makers. However, the Martindale test is also recognized and used, especially by global brands and for specific fabric types.

The Wyzenbeek method is deeply ingrained in the North American furniture industry. When a US-based client asks for a fabric with 15,000 double rubs, they are almost always referring to the Wyzenbeek test. This is a critical piece of knowledge for any supplier. Our role at Fumao is to ensure our fabrics are tested to the correct standard for your market. We use our CNAS-accredited lab to provide you with reliable Wyzenbeek test reports, giving you and your customers confidence in the product's lifespan.

Why is Wyzenbeek the preferred method in America?

The Wyzenbeek test's history and simplicity have made it the go-to standard. The machine was invented in the US, and the industry built its specifications around it. Many long-standing ASTM International standards related to upholstery fabric performance were developed with the Wyzenbeek method in mind. This creates a cycle of familiarity and trust. For American buyers, a Wyzenbeek rating is a straightforward, understood metric, making it a key factor in the sourcing decision.

Should you consider both tests for global clients?

Absolutely. While the US favors Wyzenbeek, Europe and many other international markets rely heavily on the Martindale test. If you are working with global brands or e-commerce stores that ship worldwide, having data from both tests is a powerful advantage. It demonstrates that your fabric meets global standards. We often perform dual testing for our clients who export to multiple regions. This proactive approach simplifies global logistics and compliance for our partners, ensuring their products are accepted everywhere.

How to interpret abrasion test ratings for furniture?

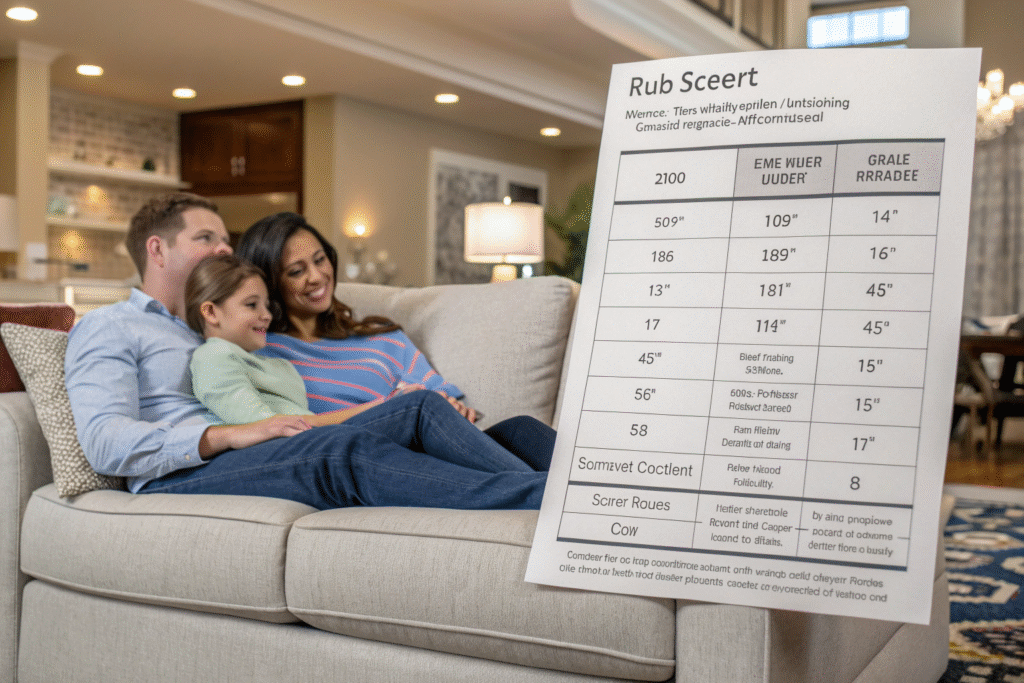

Seeing a rub count on a fabric spec sheet is one thing. Understanding what it means for a sofa in a family home is another. Test ratings are categorized into classes that suggest suitable applications. For residential use, a general guideline is sufficient. For commercial projects, the requirements are much stricter. Interpreting these ratings correctly prevents you from using a light-duty fabric in a heavy-duty setting.

The numbers tell a story of expected performance. Let's break down the common grading scales for the Wyzenbeek test, which is what many of our US clients like Ron need:

| Wyzenbeek Double Rubs | Suitable Application |

|---|---|

| 15,000+ | Heavy Residential Use |

| 30,000+ | Commercial Use (Moderate) |

| 50,000+ | Commercial Use (Heavy) |

| 100,000+ | Commercial Use (Extra Heavy) |

What are the standard durability classifications?

These classifications help you match the fabric to the furniture's purpose. A fabric rated for "heavy residential" use (15,000+ double rubs) is perfect for a family's everyday sofa. For a waiting room chair that sees constant use, you need a "commercial" grade fabric (30,000+ double rubs). We advise our clients to always aim a little higher than the minimum requirement. This builds in a safety margin and enhances the product's perceived value, which is a key part of our customer service.

Can a fabric fail in real life despite a good test score?

Yes, and this is a critical point. The abrasion test is just one part of the quality puzzle. A fabric can have a high rub count but still fail due to poor colorfastness. If the dye isn't set properly, the color will fade long before the fabric wears out. Similarly, seam slippage or pilling can ruin the appearance. This is why at Fumao, our end-to-end quality control includes more than just abrasion testing. We check for colorfastness to light and rubbing, pilling resistance, and tensile strength to ensure holistic durability.

Why is third-party fabric abrasion testing crucial?

Trust is good, but verification is better. Relying on a supplier's in-house test results can be risky. An independent, third-party lab provides an unbiased verification of the fabric's performance. This is crucial for building trust with your end-buyers, especially when selling online. It protects your brand from claims and returns. For a buyer like Ron, who is concerned about quality control, a third-party certificate is a non-negotiable proof of value.

Third-party testing removes any conflict of interest. Labs like SGS and ITS are globally recognized for their impartiality. When we send our fabrics to them for verification, it confirms that our internal CNAS lab results are accurate. This gives our partners the confidence to market their furniture with claims like "independently tested for 50,000 double rubs." This level of transparency is what sets serious suppliers apart and mitigates risk in your supply chain.

How does Fumao Textiles ensure accurate test results?

We start with control at the source. Our agile R&D team selects the right yarns and weaves for the target durability. Then, our in-house CNAS-accredited lab conducts rigorous pre-testing. This allows us to iterate and improve fabrics before they go to production. Finally, we regularly submit batch samples to third-party labs for audit. This two-layer verification system is part of our core promise to deliver reliability. It ensures that every meter of fabric you receive performs as expected.

What should you look for in a test report?

A credible test report is specific and transparent. It should clearly state the testing standard used (e.g., ASTM D4157 for Wyzenbeek), the lab that performed the test, the date, and the exact fabric batch. Be wary of vague claims like "tested for commercial use." Ask for the actual report. We make it a standard practice to provide our clients with digital copies of test reports, which they can access via our QR code tracking system for full traceability.

Conclusion

Understanding the Martindale and Wyzenbeek abrasion tests is fundamental to sourcing successful upholstery fabrics. The Wyzenbeek test's linear motion is the benchmark for the US market, while Martindale's multi-directional approach is favored elsewhere. Remember, a high rub count is important, but it must be backed by comprehensive quality control that includes colorfastness and strength testing. Ultimately, third-party verification is the key to unlocking trust and ensuring your furniture stands the test of time.

Choosing the right fabric partner makes all the difference. At Fumao Textiles International, we don't just sell fabric; we provide certified, durable solutions tailored to your market's needs. From our CNAS-accredited lab to our partnerships with third-party verifiers, we build quality and confidence into every order. If you are ready to produce high-quality clothing or furniture lines with fabrics that are proven to last, contact our Business Director Elaine to discuss your next order. Her email is elaine@fumaoclothing.com. Let's create something durable together.