As a fabric supplier with over two decades in the industry, I've seen countless orders compromised by one common enemy: fabric pilling. Those tiny, unsightly balls of fuzz not only degrade the appearance of garments but also signal poor quality to your end customers. For buyers like you, who ship from China to the U.S., this can lead to returns, damaged brand reputation, and lost revenue. Understanding the root causes of pilling is the first step to eliminating it from your supply chain.

The most effective way to avoid fabric pilling is to select the right fiber types and fabric constructions from the start, and then specify appropriate anti-pilling finishes during production. Pilling occurs when loose fibers work their way to the surface of a fabric and tangle into balls due to friction. By addressing this through raw material selection, fabric engineering, and finishing treatments, you can significantly enhance garment durability and customer satisfaction. This is a core part of our quality control process at Fumao Textiles, ensuring the fabrics we deliver meet the highest performance standards.

In this article, I will guide you through the essential strategies to prevent pilling. We will explore how your choices in fibers, yarns, and fabric construction make a difference. I will also demystify anti-pilling finishes and provide a clear framework for selecting the right one for your product line. Let's dive into the details that protect your investment.

What fabric fibers are most resistant to pilling?

Not all fibers are created equal when it comes to pilling resistance. The inherent properties of a fiber—its length, strength, and elasticity—play a fundamental role in how a fabric will perform over time. Choosing the right fiber is your first and most powerful defense against pilling.

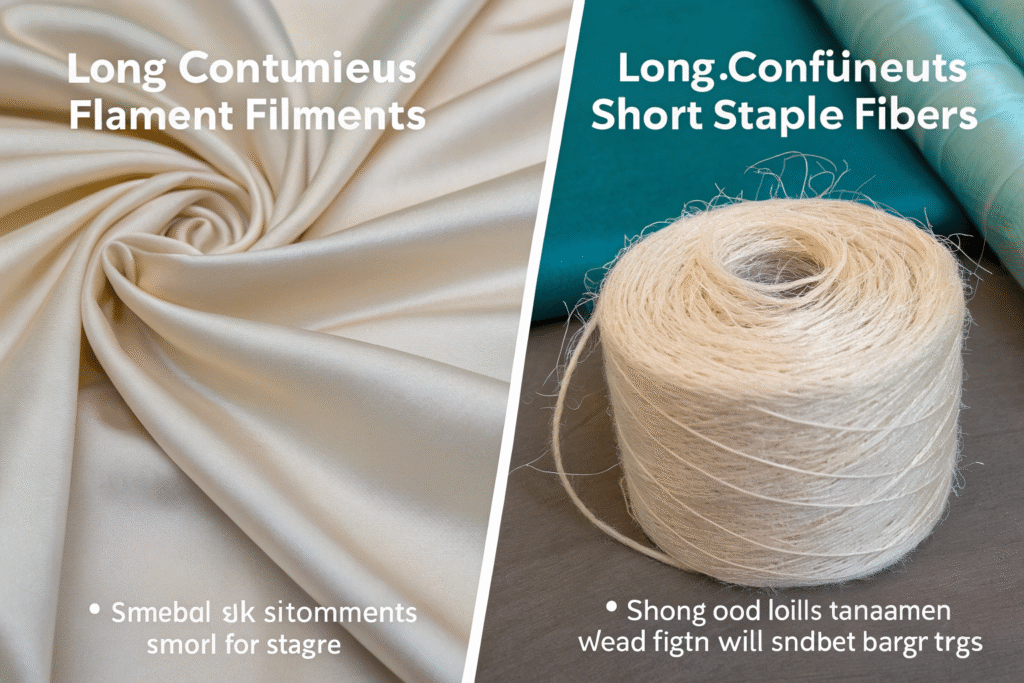

Long, continuous filaments are inherently more pilling-resistant than short, staple fibers. Think of it like hair: long hair is less likely to form tangles and knots than short, bristly hair. This is why fabrics made from silk or polyester filament are smooth and pill-free, while fabrics made from short-staple cotton or wool are more prone to pilling. The longer fibers have fewer loose ends that can work their way to the surface.

How does fiber length impact pilling?

Fiber length is a critical factor. Natural fibers like cotton, wool, and cashmere are staple fibers, meaning they have a finite length. When these shorter fibers are spun into yarn, many loose ends protrude. With friction, these ends escape the yarn structure and form pills. In contrast, synthetic fibers like polyester and nylon are often produced as filament fibers—continuous strands that are miles long. Fabrics woven or knitted from filament yarns, such as those used in many high-performance sportswear items, have a much smoother surface and superior pilling resistance. At our CNAS-certified lab, we rigorously test fiber composition to predict and prevent pilling issues before bulk production begins.

Why are synthetic fibers often better for anti-pilling?

While synthetic fibers have a reputation for pilling, this is typically only true for their staple form. High-tenacity synthetic filaments are exceptionally strong and resistant to breaking. Even when abraded, they are less likely to break and form pills compared to more delicate natural fibers. Furthermore, the development of advanced bio-degradable blends and recycled polyester allows us to engineer synthetic fabrics that are not only durable but also sustainable. For clients focused on athleisure or outdoor wear, we often recommend these high-performance options that balance eco-credentials with long-lasting quality, a key advantage for the US market where durability is highly valued.

How does fabric construction prevent pilling?

Even with the right fibers, a poor construction can lead to pilling. The way yarns are spun and how they are woven or knitted together determines the fabric's density and surface integrity. A tightly locked fabric will hold its fibers in place, while a loose one will let them escape.

Tightly woven or knitted constructions with high thread density are your best bet for minimizing pilling. When yarns are packed closely together, there is less room for fibers to migrate to the surface. For example, a tightly woven twill like gabardine or a dense knit like ponte roma exhibits excellent pilling resistance. The structure itself traps the fibers, preventing them from becoming loose and forming pills. This is a principle we apply across our diverse product portfolio, from fashion essentials to functional textiles.

What role does yarn spin play in pilling?

The type of yarn spin is crucial. Ring-spun yarns, which are soft and hairy, are more prone to pilling because of the many protruding fibers. In contrast, open-end or rotor-spun yarns are more compact and have fewer loose ends, offering better pilling resistance. For even greater durability, we recommend using piled yarns (two or more yarns twisted together). This twisting process increases the yarn's strength and makes it much harder for fibers to break free. For our clients who prioritize quality, we often specify these advanced spinning techniques to ensure their fabrics pass the most stringent SGS/ITS testing standards.

Are knitted or woven fabrics more prone to pilling?

Generally, knitted fabrics are more susceptible to pilling than woven fabrics. The looped structure of knits is naturally more flexible and stretchy, but this also means the yarns can move more freely, allowing fibers to surface. Woven fabrics, with their interlaced yarns at right angles, create a firmer, more stable structure that locks fibers in place. However, not all knits are bad. A tightly knitted Jersey or a double-knit construction can be very resilient. We guide our clients through these nuances, helping them choose the right construction—be it a robust woven canvas for workwear or a comfortable knit for children's wear—to meet their specific anti-pilling needs.

What are the best anti-pilling fabric finishes?

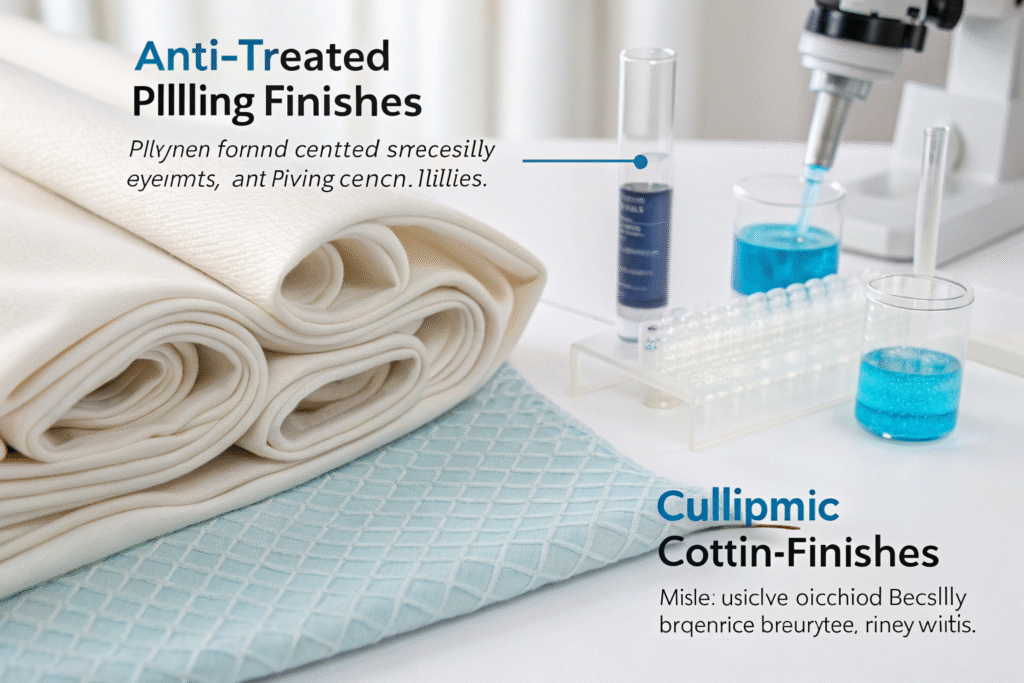

When fiber and construction choices aren't enough, anti-pilling finishes provide a powerful solution. These are chemical or mechanical treatments applied to the fabric after it is dyed or printed. They work by either reducing the ability of fibers to break or by easily shedding any micro-pills that form before they become visible.

Anti-pilling finishes typically work by applying a polymer coating that binds the fibers within the yarn, or by using enzymes to weaken the protruding fibers so they break off easily. The choice of finish depends heavily on the fiber content. For cellulosic fibers like cotton and linen, bio-polishing with cellulase enzymes is highly effective. This process gently "eats" away the micro-fibrils on the fiber surface, leaving it smoother and less likely to pill. For synthetic blends, resin-based finishes can be used to glue the fibers in place.

How does bio-polishing create pill-resistant fabrics?

Bio-polishing is an eco-friendly finishing method that uses cellulase enzymes. This process is a game-changer for natural fibers like cotton, hemp, and Tencel™. During the treatment, the enzyme selectively hydrolyzes the tiny fuzzy fibers (fibrils) on the fabric surface. This not only prevents pilling but also improves color brightness, softness, and feel. The result is a durable, high-quality fabric that maintains its new look after many washes. We've integrated this technology into our production of eco-friendly innovations, ensuring our fabrics meet both performance and sustainability goals for our European and US clients.

What should you know about resin-based anti-pilling treatments?

Resin-based finishes are another common anti-pilling solution, particularly for fabrics containing synthetic fibers like polyester or nylon. These finishes work by depositing a thin, flexible polymer film on the fabric, which effectively bonds the fibers together at their intersections within the yarn. This makes it much harder for fibers to break loose and form pills. While highly effective, it's crucial to work with a supplier that controls the application precisely, as over-application can lead to a stiff hand feel. Our partnered dyeing and finishing factories have the expertise to balance pilling resistance with the desired fabric drape and softness, a key part of our end-to-end quality control.

How to verify anti-pilling quality with your supplier?

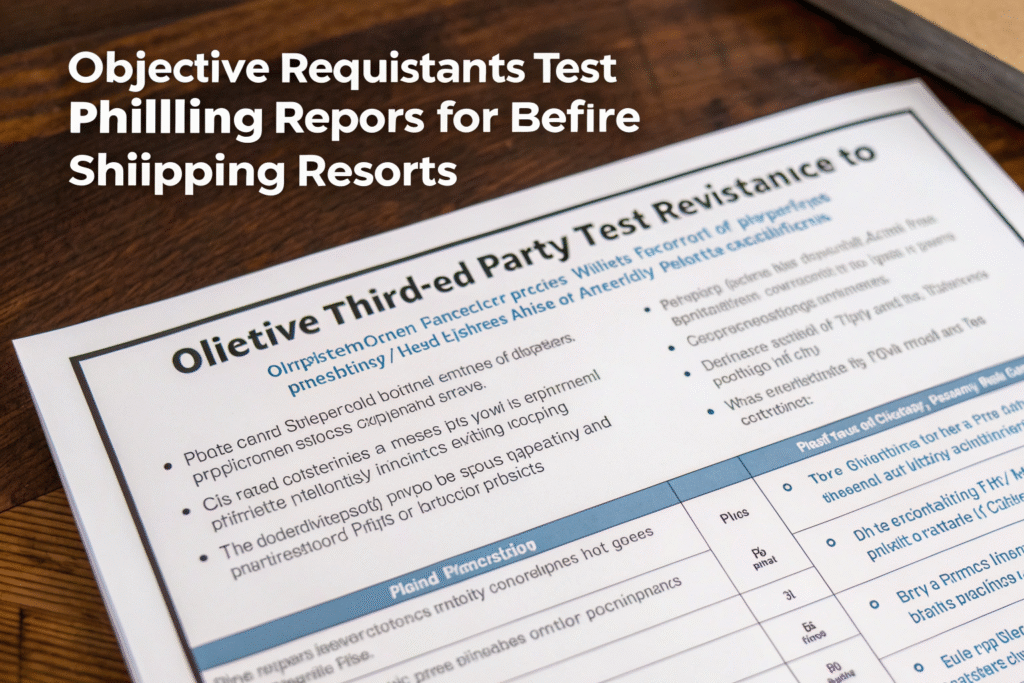

Specifying anti-pilling requirements is one thing; ensuring your supplier delivers on that promise is another. Verification through standardized testing and clear communication is non-negotiable. This is where a strong partnership with a transparent supplier pays off, saving you from costly surprises down the line.

You must insist on objective, third-party test reports for pilling resistance before shipping. Do not rely on verbal assurances. Reputable suppliers will have in-house labs capable of preliminary testing and partnerships with international certification bodies like SGS or ITS for official reports. The most common test methods are the Martindale and Random Tumble Pilling Tester methods, which simulate real-world wear and provide a rating on a scale of 1-5. A rating of 4-5 is generally considered good to excellent.

What key questions should you ask about QC testing?

Always ask your supplier specific questions about their quality control process. Key questions include: "What is the tested pilling rating for this fabric (per ASTM D4970 or ISO 12945-1)?" and "Can you provide the test report?" You should also inquire about their in-house quality control capabilities. For instance, our CNAS-accredited lab allows us to conduct rigorous pre-shipment testing, giving our clients the data they need to make informed decisions and ensuring a 98% client pass rate. This level of transparency is what sets reliable partners apart in a competitive market.

Why is a trusted supply chain crucial for consistent quality?

A complex and opaque supply chain is a major risk for quality consistency. If your fabric is woven in one factory, dyed in another, and finished in a third, communication breaks down and quality can vary. Partnering with a supplier that offers integrated control, like we do at Fumao with our owned and cooperative factories, ensures that anti-pilling specifications are adhered to at every stage. Our agile R&D and supply chain model means we oversee the process from yarn to finished fabric, guaranteeing that the quality you approved in the sample is the quality you receive in your bulk order. This integrated approach also enhances our resilience against logistical delays and helps us navigate issues like tariff costs efficiently for our US clients.

Conclusion

Preventing fabric pilling is not a matter of luck; it's a result of deliberate choices in fiber selection, fabric engineering, and finishing treatments. By understanding that long, strong fibers, tight constructions, and specialized finishes like bio-polishing are your allies, you can confidently source fabrics that look better and last longer. This knowledge empowers you to build a stronger, more reliable product line that your customers will trust.

As a leading wholesale fabric manufacturing supplier in Asia, we at Fumao Textiles are built to be your partner in quality. Rooted in Keqiao's textile cluster, we combine deep industry expertise with a fully integrated supply chain to deliver fabrics that meet your precise anti-pilling and performance standards. Let us help you eliminate the headache of pilling and ensure your shipments from China to the U.S. are seamless and successful. If you are looking to develop or source high-quality, durable fabrics for your next order, please reach out to our Business Director, Elaine. She and her team are ready to assist you. Contact Elaine at elaine@fumaoclothing.com to start a conversation today.