As a fabric supplier with over two decades in the industry, I've seen how shade variation can disrupt production schedules and impact your brand's reputation. You order 10,000 meters of what should be identical fabric, only to receive rolls with noticeable color differences. This isn't just frustrating—it's costly. Understanding why this happens is the first step toward preventing it.

Shade variation in bulk fabric occurs primarily due to inconsistencies in dyeing processes, fiber quality, and fabric handling. The good news is that these variations are preventable through rigorous quality control, standardized procedures, and strategic partnership with your fabric supplier. This common textile problem can be managed effectively with the right knowledge and processes in place.

Let's explore the root causes of this issue and identify practical strategies to ensure color consistency across your entire fabric order, safeguarding your product quality and your peace of mind.

What are the main causes of shade variation?

Shade variation can turn a perfect design into a production nightmare. I recall a client who nearly missed a major delivery deadline because of inconsistent navy blue dye lots. The problem wasn't discovered until cutting, creating massive delays and waste. This experience taught us to identify causes proactively.

The primary causes of shade variation include dye lot inconsistencies, fiber origin differences, dyeing method variations, and finishing process irregularities. These factors interact in complex ways, making shade control one of the most challenging aspects of textile manufacturing. Even with advanced technology, variations can occur without strict protocols.

How does dye chemistry affect color consistency?

Dye chemistry is perhaps the most significant factor in shade variation. Different dye batches can have slight chemical composition differences that affect how they bond with fibers. Our CNAS-certified lab consistently finds that even the same dye formula from different production batches can yield variations. The pH level of dye baths, water quality, and chemical auxiliaries all contribute to final color results. We implement strict dye standardization and testing protocols to minimize these variations. Additionally, fiber reactivity varies - natural fibers like cotton and wool absorb dyes differently than synthetic fibers like polyester, requiring adjusted dyeing approaches for consistent results.

Can fabric structure influence shade perception?

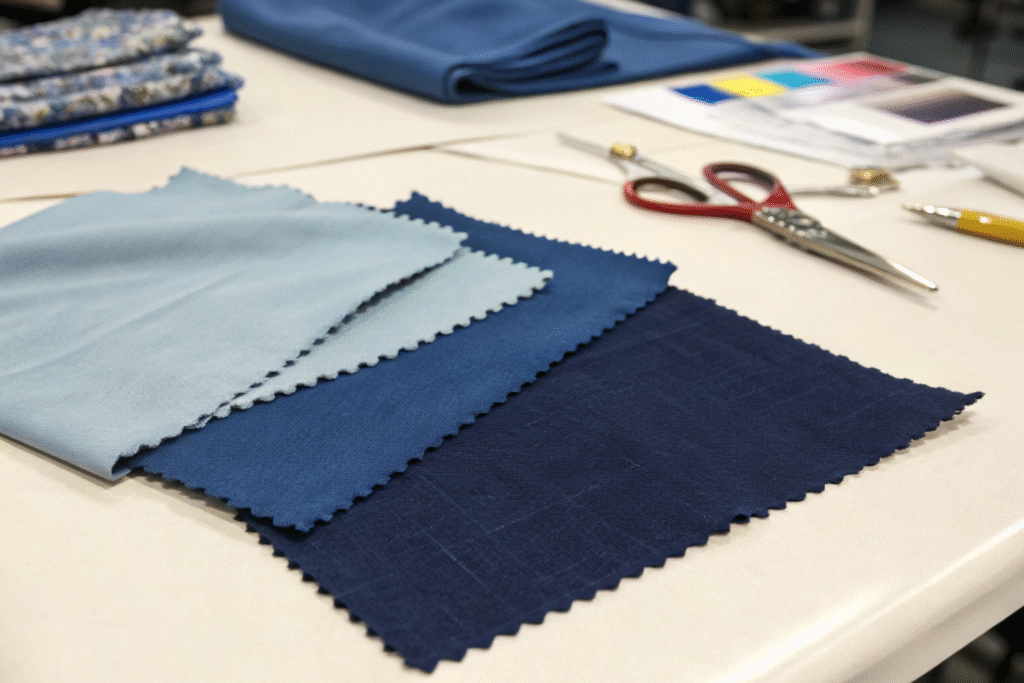

Absolutely. The same dye can appear different on various fabric constructions due to how light interacts with the surface. A twill weave will reflect light differently than a plain weave, creating visual shade differences even with identical dye formulas. During our quality control process, we've documented that fabrics with textured surfaces like jacquards or velvets show more apparent shade variation than flat surfaces like poplin. The yarn density and twist also affect dye absorption - tighter constructions often result in lighter shades as they accept less dye. This is why we recommend evaluating shades on the actual fabric construction rather than small swatches.

How can dyeing processes be standardized?

Standardizing dyeing processes is both an art and a science. When we expanded our operations to include dedicated dyeing partners, we invested six months developing comprehensive standardization protocols. The result was a 40% reduction in shade variation complaints from our European clients.

Dyeing process standardization requires controlled parameters, advanced equipment calibration, and documented procedures for every production batch. This systematic approach ensures reproducible results regardless of when or where dyeing occurs. The key is eliminating variables that introduce inconsistency.

What equipment ensures consistent dyeing?

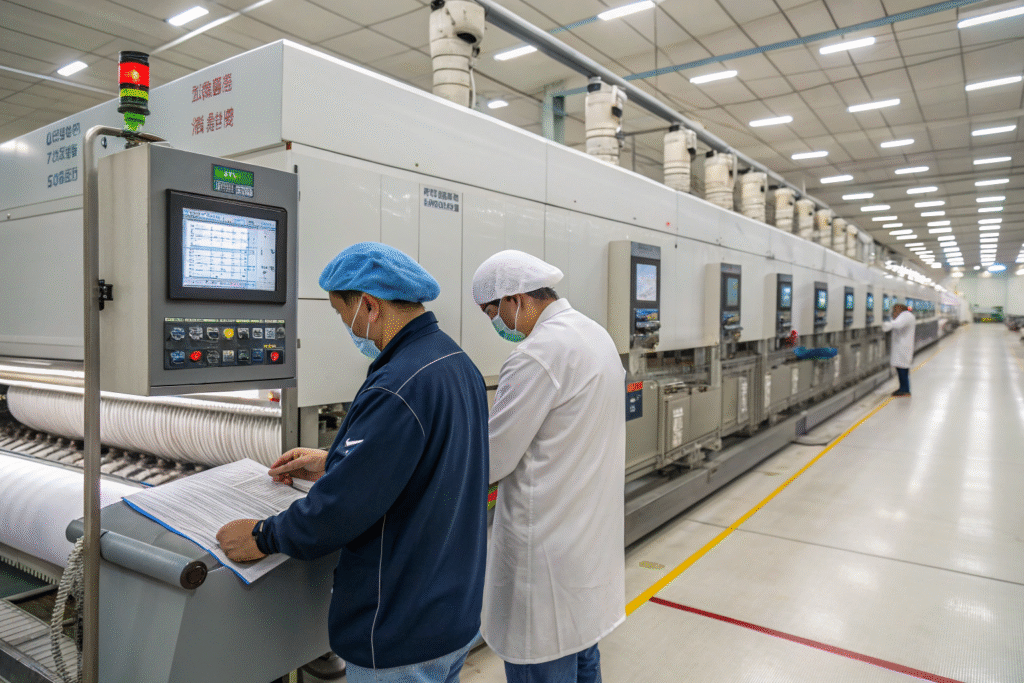

Modern dyeing machinery with computer-controlled systems is essential for consistency. We work with dye houses utilizing atmospheric jet dyeing machines and soft-flow dyeing machines that maintain exact temperature and pressure throughout the process. These systems automatically control dye cycle times, temperature ramping rates, and chemical addition sequences. The equipment is regularly calibrated and maintained according to manufacturer specifications. For synthetic fabrics like polyester, we specify high-temperature dyeing machines that ensure proper dye penetration and fixation. The right equipment investment has proven crucial for maintaining shade consistency across large production runs.

Why are dyeing parameters critical?

Dyeing parameters including temperature, time, pH, and liquor ratio must be strictly controlled and documented. Even a 2-degree temperature variation can alter shade significantly. We maintain detailed technical sheets for each fabric type that specify exact parameters throughout the dyeing cycle. Our quality team monitors these parameters during production audits and verifies them against the approved standard. The water quality used in dyeing is equally important - we require our partners to use treated water with consistent mineral content. This attention to parameters might seem excessive, but it's what enables us to achieve 98% client pass rates for color consistency.

What quality control prevents shade issues?

Quality control is our frontline defense against shade variation. I've personally trained our QC team to spot subtle color differences that automated systems might miss. This human element, combined with technology, creates a robust detection system.

Effective quality control for shade variation involves both instrumental color measurement and visual assessment under standardized lighting conditions. This dual approach catches variations that either method alone might miss. Our process begins at lab dip stage and continues through bulk production.

How does spectrophotometer testing work?

Spectrophotometers provide objective color measurement by quantifying color numerically using CIELAB values (L, a, b*). We use these devices to establish a digital color standard for each shade, then measure production samples against this standard. The instruments detect color differences that are visually imperceptible, allowing for corrections before full production. Our CNAS-accredited testing center employs multiple spectrophotometers that are regularly calibrated to ensure measurement consistency. We typically set a Delta E tolerance of 0.8-1.2 for solid shades, depending on client requirements and fabric type. This scientific approach removes subjectivity from color approval.

Why is proper lighting essential for shade assessment?

The human eye perceives color differently under various light sources, a phenomenon called metamerism. We conduct visual shade assessments in specialized light booths containing multiple standardized light sources including D65 (daylight), TL84 (store lighting), and incandescent. This ensures the color appears consistent across different viewing environments. Our assessors are trained to evaluate shades at 45-degree angles to simulate real-world viewing conditions. For fabrics destined for specific retailers, we often use their preferred lighting conditions for assessment. This comprehensive approach has significantly reduced returns due to shade issues under different lighting.

How to maintain shade consistency in bulk production?

Maintaining shade consistency from the first to the last meter of a 10,000-meter order requires systematic planning and execution. We developed our current protocols after a challenging order where the beginning and end of the production run showed noticeable shade variation.

Maintaining shade consistency in bulk production requires continuous monitoring, proper batch management, and standardized finishing processes. The goal is to identify and address drift before it becomes unacceptable. This proactive approach saves both time and materials.

What is lot numbering and why does it matter?

Lot numbering tracks fabric through every production stage, creating accountability and traceability. We assign unique lot numbers to each dye batch and maintain these identifiers through finishing and inspection. This system allows us to isolate any variation and address it promptly. When cutting multiple lots for large orders, we advise clients on optimal lay planning to distribute minor variations evenly throughout garments. Our digital QR code tracking system provides real-time access to lot information, composition, and test reports. This transparency has been particularly valued by brands with stringent sustainability and traceability requirements.

How does finishing affect final shade?

Finishing processes including heat setting, calendering, and softening can alter fabric shade significantly. We standardize finishing parameters including temperature, speed, and chemical applications to minimize these effects. For instance, the heat setting temperature for polyester fabrics must be consistent to prevent shade changes. We conduct shade evaluations after finishing rather than after dyeing alone, as the final appearance is what matters to our clients. Some special finishes like water repellency or antimicrobial treatments may require additional testing to ensure they don't affect color. Our integrated approach from dyeing through finishing ensures the shade you approve is the shade you receive.

Conclusion

Shade variation in bulk fabric production stems from multiple factors including dye chemistry inconsistencies, process parameter variations, and inadequate quality control. However, with proper understanding and implementation of standardized procedures, these variations can be effectively managed and prevented. The key lies in selecting partners with robust systems, advanced equipment, and proven expertise in color management.

At Fumao Textiles, we've built our reputation on delivering consistent quality, with color consistency being a cornerstone of our service. Our integrated supply chain, from dyeing through finishing, allows us to maintain control at every step. If you're looking for a reliable partner who understands the critical importance of shade consistency in your production, we invite you to contact our Business Director Elaine at elaine@fumaoclothing.com. Let us help you ensure that every garment in your collection matches perfectly, order after order.