As a fabric supplier with over two decades in the textile hub of Keqiao, I've seen countless orders succeed or fail based on one critical factor: colorfastness. A vibrant print or a rich dye means nothing if it bleeds in the wash or rubs off onto other garments. This isn't just an aesthetic issue; it's a direct hit to your brand's reputation and your bottom line. For buyers like you, sourcing fabrics that maintain their color through repeated washing and daily friction is non-negotiable.

The good news is that modern textile finishing technologies offer powerful solutions to dramatically enhance colorfastness to both rubbing (crocking) and washing. These finishes work by either forming a protective film on the fabric surface or by chemically bonding with the dye molecules to lock them into the fibers. The right finish depends on the fiber content, the dye type, and the intended use of the final product.

Understanding these finishes is key to making informed sourcing decisions. It helps you ask the right questions and ensures you receive fabric that meets your quality standards, shipment after shipment. Let's dive into the specific chemical and mechanical finishes that can solve these persistent colorfastness challenges for your clothing lines.

What are the best chemical finishes for colorfastness?

Chemical finishes are applied to fabric through a process of padding, drying, and curing. They alter the fabric at a molecular level to improve its performance. For colorfastness, the goal is to create a strong bond between the dye and the fiber, preventing color migration.

How do cationic softeners enhance wet rub fastness?

Cationic softeners are a popular dual-action finish. They not only improve the soft hand-feel of the fabric but also significantly boost its colorfastness to wet rubbing. These softeners carry a positive ionic charge. Most dye molecules and fabric fibers, like cotton, carry a negative charge. The cationic softener is attracted to the fabric and the dye, forming a protective molecular bridge that helps lock the dye in place. This reduces the amount of free dye on the surface that can be transferred during abrasion. In our production, we often use this finish for dark-colored cotton jersey and linen blends, which are notoriously prone to crocking. It's a cost-effective way to elevate the quality of base fabrics.

Can cross-linking agents prevent dye bleeding in washes?

Yes, cross-linking agents are one of the most effective defenses against dye bleeding during washing. These resins create durable covalent bonds between the dye molecules and the cellulose chains in natural fibers like cotton and viscose. Think of it as building a strong, three-dimensional net that traps the dye within the fiber. This net prevents the dye from solubilizing and escaping into the wash water. For our clients who produce high-end activewear or uniforms that require frequent laundering, we always recommend finishes with cross-linking agents. They are a cornerstone of our quality control for eco-friendly fabrics like organic cotton, ensuring the colors stay bright and true without compromising the garment's sustainability credentials.

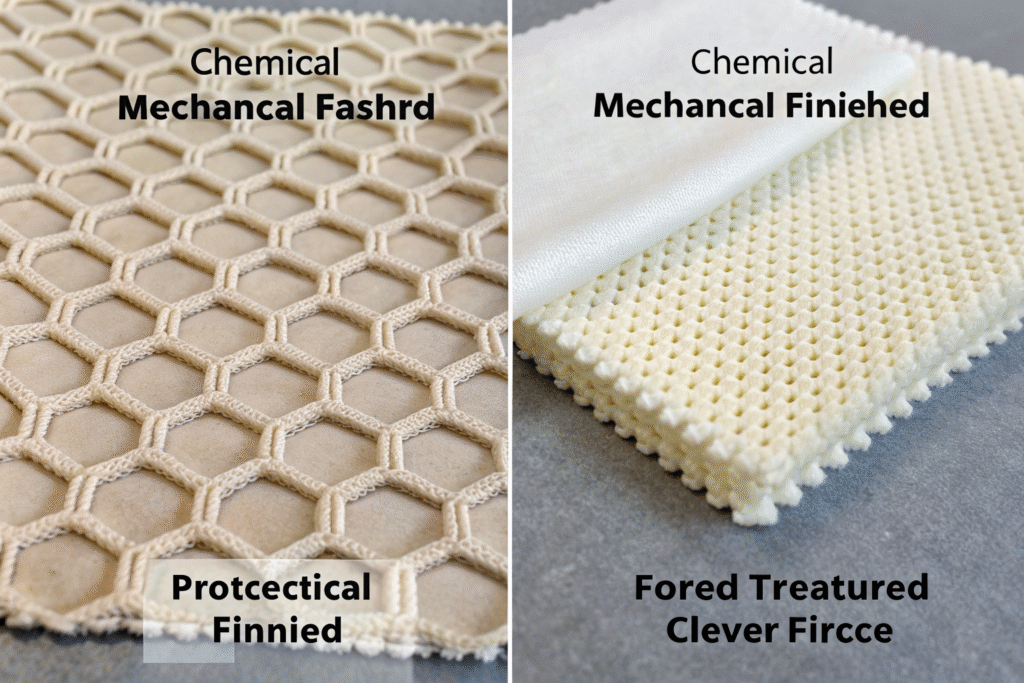

Which mechanical finishes create a color-locking barrier?

While chemical finishes work on a molecular level, mechanical finishes use physical force, pressure, and heat to change the fabric's surface properties. These processes can compact the fabric structure or add a physical layer of protection, making it harder for color to escape.

Does calendering improve fabric surface and color retention?

Calendering is a process where fabric is passed under high-pressure rollers, often with heat. This polishes the fabric surface, flattening the fibers and yarns. A smoother surface has fewer protruding fibers to abrade and release dye during a rub test. It also makes the fabric less porous, reducing the pathways for dye to migrate out during washing. We frequently use calendering on poplin and satin weaves for shirts and blouses. It enhances the fabric's luster and provides a superior base for printing, ensuring the prints are sharp and resistant to cracking or fading. It's a classic mechanical finish that delivers proven results for both colorfastness and aesthetics.

How does sanforization stabilize fabric and prevent fading?

Sanforization is a controlled compressive shrinkage process, primarily used for cotton wovens like denim. While its main goal is to pre-shrink the fabric, it also has a positive impact on colorfastness. The process involves moistening the fabric and then passing it through a rubber belt and heated cylinder, which compresses the yarns. This compression creates a denser fabric structure. A denser structure means the dye is more securely trapped within the yarn. For denim, especially garment-dyed or washed styles, sanforization helps minimize color loss in subsequent laundry cycles. It's a crucial step for ensuring your jeans maintain their iconic color after multiple home washes.

How do fabric-specific finishes target colorfastness issues?

Different fibers have unique characteristics, and therefore, require tailored finishing approaches. A one-size-fits-all strategy does not work in advanced textile manufacturing.

What finishes are essential for cotton and other cellulosics?

Reactive dyes are standard for cotton, but they can be prone to hydrolysis, leaving unfixed dye that causes bleeding. Fixing agents are the essential finish here. These chemicals, such as cationic fixing agents, form an insoluble complex with the hydrolyzed reactive dyes, preventing them from washing out. For premium cotton products, we combine fixing agents with a thorough soaping-off process after dyeing to remove any loose dye before the finish is even applied. This two-pronged approach is a standard part of our end-to-end quality control and is critical for meeting the strict colorfastness standards of brands like H&M or ZARA.

Which solutions work for synthetic fibers like polyester?

Polyester is dyed with disperse dyes, which are mechanically trapped inside the thermoplastic fiber. The primary colorfastness challenge is "sublimation" – where the dye turns directly from a solid to a gas under heat, leading to color transfer. The key finish for polyester is a high-quality heat setting. By subjecting the dyed fabric to precise, high heat, we cause the polymer chains in the polyester to crystallize and lock around the dye molecules. This process is vital for performance fabrics used in sportswear, which are exposed to body heat and friction. Our CNAS-certified lab rigorously tests for sublimation fastness to ensure our fabrics pass muster.

What quality control measures ensure lasting colorfastness?

A finish is only as good as the system that verifies its effectiveness. At Fumao, we believe in proving our quality with data, not just promises.

How is rubbing fastness tested in a certified lab?

We use a device called a Crockmeter to test for both dry and wet rubbing fastness. A white cotton test cloth is mounted on a finger, which then rubs against the fabric sample a specified number of times under controlled pressure. The amount of color transferred to the white cloth is then assessed against the AATCC Gray Scale for Staining. A grade of 4-5 means excellent fastness with minimal transfer, while a low grade like 2 indicates poor performance. This objective test is a non-negotiable step in our process for every bulk order, and the results are available to our clients through our advanced QR code tracking system.

What standards govern washing fastness testing?

Washing fastness is tested according to international standards like AATCC Test Method 61 or the equivalent ISO 105-C06. In these tests, fabric samples are laundered with specified multi-fiber strips in a controlled solution for a set number of cycles. The change in the sample's color and the staining of the multi-fiber strip are then evaluated. This tells us not only if the fabric itself fades but also if it will stain other garments washed with it. We conduct these tests in our in-house lab, and also partner with third-party agencies like SGS for independent verification, ensuring our clients have the documentation needed for major market entry.

Conclusion

Choosing the right fabric finish for colorfastness is not a matter of guesswork; it's a strategic decision based on fiber content, dye type, and end-use. From chemical workhorses like cross-linking agents and cationic softeners to mechanical processes like calendering and sanforization, the toolbox available to a reliable supplier is extensive and effective. The true mark of quality, however, lies in the rigorous quality control that certifies these finishes perform as promised, batch after batch.

As a partner deeply rooted in the Keqiao textile ecosystem, we have the expertise and infrastructure to guide you to the optimal solution for your specific needs. We don't just sell fabric; we deliver confidence that your products will look vibrant and professional long after they leave the store. If you are looking for a supplier who prioritizes durable quality and transparent testing, let's start a conversation about your next order.

For a direct conversation about how we can ensure the colorfastness of your fabric orders, please reach out to our Business Director, Elaine. She and her team are ready to assist you with your sourcing needs. You can contact her at elaine@fumaoclothing.com.