As a fabric supplier with over two decades in the textile hub of Keqiao, I often hear this question. Brands and buyers, especially those shipping from China to the U.S. like our client Ron, are increasingly focused on sustainable materials. They want to ensure their eco-friendly claims are backed by solid, verifiable proof. This is where the Global Recycled Standard (GRS) comes into play.

GRS certification is an international, voluntary standard that tracks and verifies the recycled content in a final product. It covers the entire supply chain, from the recycled raw material to the final seller. For recycled polyester fabric, it certifies that the material is made from post-consumer or post-industrial waste, and that its production follows strict environmental and social criteria. This certification gives brands a trusted badge of authenticity for their sustainability efforts.

Understanding GRS is crucial for any business serious about green textiles. It's not just a label; it's a comprehensive system that builds trust with your customers. Let's break down what this means for your fabric sourcing strategy.

Why is GRS certification important for US importers?

For American importers, navigating tariffs, logistics, and quality control is complex enough. Adding sustainability into the mix can seem daunting. However, GRS certification directly addresses several key pain points for US businesses, turning a potential hurdle into a significant competitive advantage.

It provides a bulletproof verification system. When you claim a product is made from recycled materials, you need proof that can withstand scrutiny from regulators and environmentally conscious consumers. The GRS offers exactly that through its robust chain-of-custody requirements. This traceability mitigates the risk of greenwashing accusations, protecting your brand's reputation. For businesses focused on quality and development capacity, this certification is an extension of that commitment, ensuring the material's integrity from the very beginning.

How does GRS certification mitigate supply chain risks?

A certified supply chain is a transparent and managed supply chain. The GRS requires every entity involved in the production of your fabric—from the recycling plant to the spinner, weaver, and dyer—to be certified. This creates a documented and audited trail. For you, this means significantly reduced risk of fraud or inconsistent material quality. You are not just taking a supplier's word for it; you have an independent, third-party verification that the recycled content is genuine. This level of oversight is invaluable, especially when managing long-distance supply chains from Asia. It aligns perfectly with the need for rigorous quality control throughout the production process.

What competitive edge does GRS offer in the US market?

The US market, particularly in segments like activewear and eco-fashion, is highly responsive to authentic sustainability stories. GRS certification is not just a technical document; it's a powerful marketing tool. It allows you to use the official GRS logo on hangtags and in marketing campaigns, providing immediate credibility. This can be a decisive factor for retailers and end-consumers who prioritize environmental responsibility. Furthermore, it future-proofs your business against increasingly strict environmental regulations and can even influence tariff costs as policies evolve to favor sustainable goods. It's an investment that pays off in both brand value and market access.

What are the key requirements to achieve GRS certification?

Achieving GRS certification is a rigorous process that demands commitment from every level of the supply chain. It's far more than just using recycled materials; it's about building a system that ensures integrity, responsibility, and transparency from the ground up. Understanding these requirements helps you partner with a supplier who is genuinely compliant, not just making claims.

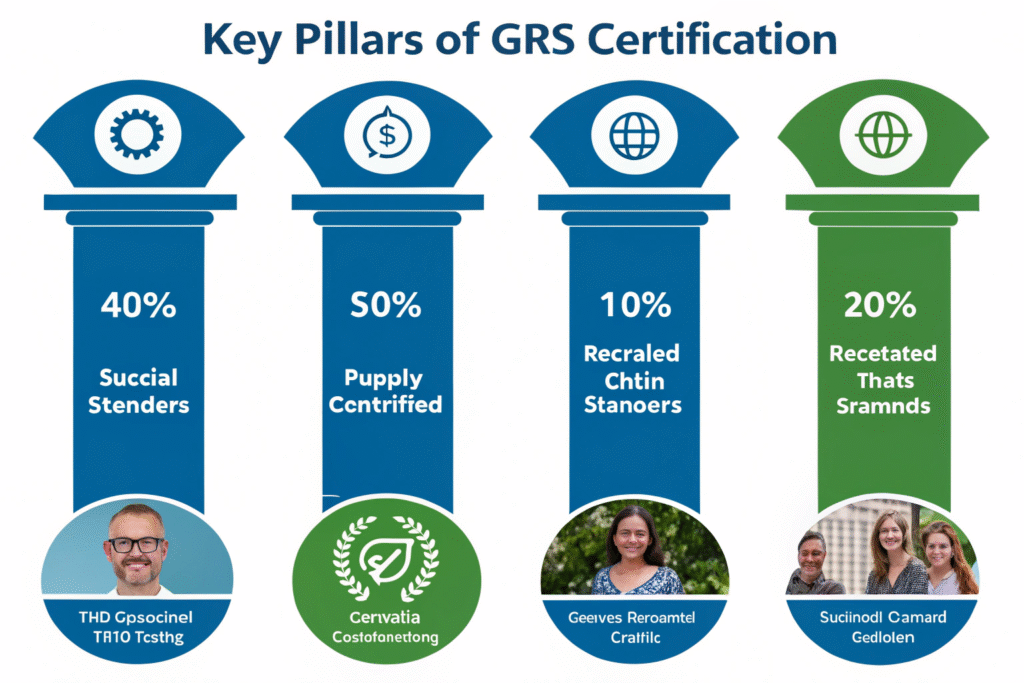

The core requirements can be broken down into four pillars. First, the product must contain a minimum of 20% recycled content to be eligible for certification, with tiers (50%, 100%) allowing for more specific claims. Second, there is a strict Chain of Custody requirement that tracks the recycled material from its source to the final product. Third, environmental criteria mandate responsible chemical use, water management, and energy reduction. Finally, social criteria require compliance with strict labor standards, ensuring safe working conditions.

What is the minimum recycled content for GRS?

The GRS sets a clear threshold: a product must contain at least 20% certified recycled material by weight to be eligible for any GRS claim. However, the standard uses a tiered system to encourage higher recycled content. If a product contains between 20% and 95% recycled material, it is labeled as "GRS - XX% Recycled." Only products with 95% to 100% recycled content can be labeled as "100% Recycled" under the GRS. This system provides flexibility and rewards manufacturers and brands for maximizing their use of recycled polyester from post-consumer plastic bottles.

How are environmental and social criteria enforced?

Enforcement is carried out through independent, third-party audits. A certification body accredited by the Textile Exchange, the organization that manages the GRS, conducts on-site audits of the manufacturing facilities. They inspect records, interview workers, and assess processes against the standard's strict checklist.

| Criteria Category | Key Enforcement Points |

|---|---|

| Environmental | Monitoring of chemical use (restricted substances list), wastewater treatment, energy consumption tracking. |

| Social | Compliance with local labor laws, prohibition of forced or child labor, ensuring safe working conditions and fair wages. |

This audit process verifies that a company like ours is not only producing recycled fabric but is doing so in an environmentally and socially responsible way. This aligns with the values of many global brands and their need for comprehensive sustainability commitment in their partners.

How does Fumao Textiles implement GRS in production?

At Fumao Textiles, GRS certification is not a side project; it's integrated into our core operational DNA. Our position within the Keqiao textile cluster gives us a unique advantage, allowing us to control and coordinate a fully certified supply chain. For a buyer like Ron, who values efficiency and quality, our system is designed to deliver GRS-certified fabrics without compromising on speed or performance.

Our implementation starts at the source. We work exclusively with GRS-certified recycling facilities that provide traceable rPET (recycled polyester) chips. These chips are then sent to our partner spinning and weaving mills, which are also GRS-certified. This ensures the chain of custody remains unbroken from the very beginning. Our in-house CNAS-certified lab plays a crucial role, conducting pre-testing on the recycled yarns and fabrics to ensure they meet our stringent quality standards before they even enter the full production cycle.

What is your process for maintaining chain of custody?

Maintaining the chain of custody is a meticulous, document-driven process. Every batch of GRS-certified recycled material enters our supply chain with a Transaction Certificate (TC) from its supplier. As the material moves through each stage—spinning, weaving, dyeing, finishing—we generate new TCs. This paper trail is audited regularly to ensure that the volume of certified material input matches the volume of certified fabric output. We leverage technology, including QR code tracking, to provide our clients with real-time visibility into this process, offering peace of mind that their logistics and documentation are handled with integrity.

How do you ensure quality in recycled polyester fabric?

A common misconception is that recycled polyester is inferior in quality. We prove otherwise. Our R&D team has developed specialized processes for working with recycled yarns to ensure they match the performance and hand-feel of virgin polyester. This includes:

- Advanced Filtration: Melting and extruding the rPET with high-precision filters to ensure yarn consistency and strength.

- Customized Finishing: Applying functional finishes like moisture-wicking and UV protection that bond effectively with the recycled fibers.

Through rigorous testing in our lab for pilling resistance, colorfastness, and tensile strength, we guarantee that our GRS-certified fabrics meet the same high standards as our conventional ones, delivering the quality and development capacity our clients expect.

How can GRS-certified fabric reduce my overall costs?

While the initial price per meter of GRS-certified fabric might be higher, a holistic view reveals significant opportunities for cost reduction and value creation. For a cost-conscious buyer, this long-term perspective is essential for making a smart sourcing decision. It's about total cost of ownership, not just unit price.

The most direct financial benefit can be tariff costs. While subject to change, various legislative initiatives and potential future policies may offer preferential treatment for sustainably manufactured goods, including reduced import duties. Furthermore, by using GRS-certified recycled polyester, you are insulating your business from the price volatility of virgin polyester, which is tied to the fluctuating crude oil market. This creates more predictable and stable long-term costing for your collections.

Can GRS certification lead to faster market approval?

Absolutely. In today's retail landscape, major brands and retailers have their own stringent sustainability mandates. When you present a GRS-certified fabric, complete with its Transaction Certificates, you are essentially providing a pre-verified, compliant material. This can dramatically shorten the internal approval processes within your client's organization. There's no need for them to conduct their own lengthy background checks on the material's origin; the certification does the talking. This speed-to-market is a critical competitive advantage, aligning perfectly with the need for fast production and development cycles.

Does it simplify compliance with brand sustainability mandates?

Yes, it simplifies compliance immensely. Almost every major global brand now has a publicly stated sustainability goal. Sourcing GRS-certified materials is one of the most straightforward ways to meet these mandates. It's a universally recognized standard that sourcing managers and compliance officers understand and trust. Instead of navigating a complex web of different client-specific requirements, you can use the GRS as a single, comprehensive solution. This reduces administrative overhead, minimizes the risk of failed compliance audits, and makes you a more attractive and reliable supplier to top-tier brands.

Conclusion

GRS certification for recycled polyester fabric is far more than an eco-label. It is a comprehensive system that verifies recycled content, ensures ethical production, and builds undeniable trust with the end-consumer. For US importers, it directly addresses critical concerns around supply chain transparency, risk mitigation, brand value, and long-term cost management. It transforms a sustainability claim into a tangible, marketable, and strategic business asset.

Partnering with a supplier who has deeply integrated GRS into their production, like Fumao Textiles, is the key to unlocking these benefits. We handle the complexities of certification and quality control, delivering you fabrics that are not only environmentally sound but also high-performing and reliable. If you are ready to leverage GRS-certified fabrics for your next clothing order and streamline your sourcing from China, we should talk. Contact our Business Director, Elaine, today to discuss your specific needs at elaine@fumaoclothing.com. Let's co-create value for your brand and the planet.