As a fabric supplier with over two decades in the industry, I hear this question constantly. Choosing the right fabric for workwear uniforms isn't just about comfort; it's a critical decision impacting safety, durability, and overall cost-effectiveness. A uniform that wears out too quickly leads to frequent replacements, increasing expenses and potentially compromising worker protection. So, how do you navigate the complex world of textiles to find the perfect balance?

The best fabrics for high-abrasion-resistant workwear uniforms are typically those engineered with durable fibers and robust constructions. Fabrics like polyester-cotton ripstop, canvas, and high-density nylon are top contenders. Their exceptional durability stems from strong synthetic fibers and specialized weaves designed to withstand friction, tears, and repeated washing. The key is matching the fabric's properties to the specific demands of the work environment.

Let's dive into the essential factors that define superior abrasion resistance. We will explore the best fabric types, their key performance characteristics, and how to ensure your chosen uniform meets the highest standards of quality and protection. This guide will equip you with the knowledge to make an informed purchase that safeguards your team and your budget.

What are the top durable fabrics for workwear?

When your workwear must endure daily grind, not all fabrics are created equal. The top performers combine tough fibers with intelligent construction to resist wear and tear. From the factory floor to the great outdoors, these fabrics have proven their mettle.

Why is Polyester-Cotton Blend a industry staple?

Polyester-cotton blend is the undisputed champion of the workwear world for good reason. It masterfully combines the best qualities of both fibers. The polyester component provides high tensile strength and excellent abrasion resistance, ensuring the fabric can handle rough surfaces and repeated friction. It also dries quickly and resists wrinkles and shrinking. The cotton aspect offers breathability and comfort against the skin, making the uniform wearable for long shifts. Common blends like 65% polyester and 35% cotton create a fabric that is tougher than pure cotton while being more comfortable than pure polyester. This blend is also cost-effective and readily available, making it a practical choice for outfitting large teams. For heavy-duty applications, a tighter weave like a 2x2 twill construction further enhances its durability.

How does Nylon and Ripstop Weave enhance durability?

Nylon is inherently one of the strongest synthetic fibers, renowned for its exceptional resistance to abrasion and tearing. When woven into a ripstop pattern, its durability is taken to the next level. The ripstop weave incorporates thicker reinforcement threads at regular intervals, creating a grid-like pattern that effectively stops small tears from propagating. Think of it as a safety net woven directly into the fabric. This makes ripstop nylon ideal for workwear in environments with sharp edges or snag hazards, such as construction, landscaping, or utility work. Furthermore, nylon fabrics can be coated or treated to become water-resistant or flame-retardant, adding critical layers of protection for specialized industries. Its high strength-to-weight ratio means you get maximum durability without unnecessary bulk or weight, enhancing worker mobility.

How to evaluate fabric strength and abrasion resistance?

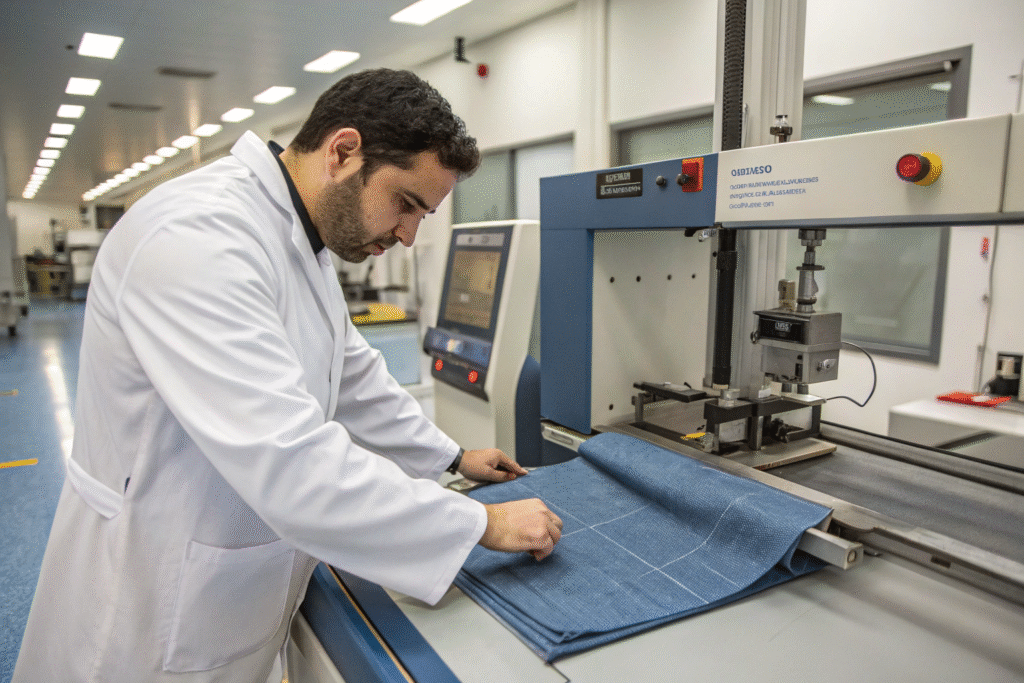

Knowing which fabrics are available is only half the battle. Understanding how to objectively measure and compare their durability is crucial for making a smart investment. This involves looking at standardized tests and tangible fabric properties.

What is the Martindale Test for abrasion?

The Martindale test is a globally recognized method for quantifying a fabric's resistance to abrasion. In this laboratory test, a fabric sample is rubbed against a standard abradant (like wool) in a continuous circular motion under a fixed pressure. The result is expressed in "cycles." The higher the number of cycles a fabric can endure before showing signs of breakage (like a hole or significant threadbare spot), the better its abrasion resistance. For general workwear, a rating of 15,000 to 25,000 cycles may be sufficient. For heavy-duty applications, you should look for fabrics with ratings exceeding 30,000 cycles. Relying on this objective data, rather than vague marketing claims, allows for a true apples-to-apples comparison between different fabric options and ensures the uniform will stand up to your specific workplace demands.

Why does Fabric Weight and Denier matter?

Fabric weight and denier provide a quick, initial gauge of durability. Fabric weight, often measured in grams per square meter (GSM) or ounces per square yard (oz/yd²), indicates the mass of the fabric. Heavier fabrics generally use thicker yarns or a denser weave, resulting in more material to withstand wear. However, weight alone isn't a perfect indicator; construction is key. Denier, a unit for measuring the linear mass density of fibers, refers to the thickness of the individual threads. A higher denier means a thicker, and typically stronger, fiber.

| Metric | What It Measures | Indication for Durability |

|---|---|---|

| Fabric Weight (GSM) | Mass per unit area | Heavier weight often suggests a denser, more substantial fabric. |

| Denier | Thickness of individual fibers | Higher denier indicates thicker, more robust fibers. |

For instance, a 600D nylon fabric will be more resistant to punctures and abrasion than a 300D nylon fabric. A common specification for durable workwear might be a "10 oz, 600D polyester" fabric. It's important to balance these numbers with breathability, as a very high GSM or Denier might make the garment less comfortable in warm conditions.

What are the benefits of blended fabrics for workwear?

Pure natural or synthetic fibers often have specific weaknesses. Blending different fibers creates a synergistic effect, producing a fabric that outperforms any of its individual components. This is the cornerstone of modern high-performance workwear.

How do blends improve performance and comfort?

Blended fabrics are engineered to overcome the limitations of single-fiber fabrics. As mentioned, polyester-cotton blends are a prime example, but other blends are equally powerful. For instance, adding a small percentage of Spandex (also known as Lycra or elastane) to a cotton or polyester fabric introduces stretch. This freedom of movement reduces stress on the fabric seams and material during bending, kneeling, and reaching, which directly translates to improved abrasion resistance and garment longevity. Furthermore, blends can enhance comfort; moisture-wicking polyester can be blended with soft cotton to move sweat away from the body while maintaining a soft hand feel. For flame-resistant (FR) applications, blends of aramid fibers like Nomex and Kevlar with other FR fibers offer a balance of protection, comfort, and cost that pure aramids might not achieve alone.

Can blended fabrics reduce long-term costs?

Absolutely. While the initial price per garment of a high-quality blended fabric might be slightly higher, the Total Cost of Ownership (TCO) is often significantly lower. A more durable blend withstands abrasion and repeated industrial laundering far better than a cheaper, less resilient alternative. This means fewer replacements are needed over time. A uniform that lasts twice as long effectively cuts your uniform expenditure in half. Additionally, features like wrinkle resistance in polyester blends can reduce ironing needs and energy costs associated with upkeep. By investing in a superior blended fabric, you are not just buying a uniform; you are investing in an asset that delivers value through extended service life and reduced operational downtime for change-outs.

How to ensure quality in abrasion-resistant workwear?

Identifying a good fabric on paper is one thing; guaranteeing it performs in the real world is another. Rigorous quality control and a reliable supply chain are non-negotiable for ensuring every uniform batch meets your high standards.

What quality certifications should you look for?

Certifications from independent third-party organizations provide a crucial layer of assurance. They verify that the fabric has been tested and meets specific safety and performance benchmarks. Key certifications to look for include:

- OEKO-TEX Standard 100: This certifies that the fabric is free from harmful levels of more than 100 substances known to be detrimental to human health. This is vital for garments worn against the skin for long periods.

- ISO 9001: This indicates that the manufacturer has a certified Quality Management System in place, ensuring consistency and continuous improvement in their processes.

- Specific Performance Standards: Look for test reports from labs like SGS or ITS that confirm the fabric meets standards for abrasion (like Martindale), tear strength, and colorfastness. For specialized work, certifications for Flame Resistance (FR) or high-visibility (EN ISO 20471) are essential.

Why is a reliable supply chain critical for consistency?

A complex, fragmented supply chain introduces variables that can compromise quality. If weaving, dyeing, and finishing occur in different, poorly coordinated factories, consistency in fabric treatment and final quality is hard to maintain. As a manufacturer controlling our own large-scale weaving and cooperating closely with certified dyeing and finishing partners, we see this firsthand. A vertically integrated or tightly managed supply chain ensures that every production step, from sourcing the raw yarn to the final inspection, adheres to the same strict protocols. This control is what guarantees that the 10,000th meter of fabric is identical in strength, color, and performance to the first. It also enables faster response times and greater flexibility for customization, ensuring you get exactly what you need, when you need it.

Conclusion

Selecting the best fabric for high-abrasion-resistant workwear is a multi-faceted process. It requires a deep understanding of fiber types, fabric constructions like ripstop and twill, and the proven benefits of blended materials. Beyond the material itself, objective evaluation through tests like Martindale and a commitment to verifiable quality certifications are paramount. The ultimate goal is to find a partner who provides not just a fabric, but a durable, safe, and cost-effective uniform solution that protects your workforce and your bottom line.

Your team deserves workwear that works as hard as they do. If you are looking for a reliable partner to co-develop and manufacture your next workwear uniform order with fabrics built to last, we are here to help. Our expertise in durable fabric solutions and end-to-end quality control ensures you get the best performance and value. For a direct conversation, please reach out to our Business Director, Elaine, at elaine@fumaoclothing.com. Let's build something durable together.