As a fabric supplier with over two decades in China's textile hub, Keqiao, I often get asked about specialty finishes. Brand owners want their fabrics to stand out. They come to me confused about techniques like foil print and lamination. They look similar—both can be shiny and metallic. But they are fundamentally different processes with different costs, feels, and applications. Choosing the wrong one can ruin a design and waste a lot of money. Understanding their core differences is the first step to making the right choice for your fashion line or technical apparel.

The key difference between foil printing and lamination lies in the process and the resulting fabric properties. Foil printing is a selective, heat-transfer method that applies a metallic or pigmented design onto the fabric surface. Lamination is a process that bonds a continuous, solid film layer to the entire back or front of the fabric, fundamentally changing its performance. Foil print is primarily for aesthetics, adding shiny patterns. Lamination is primarily for function, creating properties like waterproofness or windproofness. One is a surface decoration; the other is a composite construction.

Let's peel back the layers on these two popular fabric treatments. We will explore how each process works, what they feel like, their key strengths, and how to decide which one is perfect for your next product. This knowledge will save you time, control costs, and ensure your final garment looks and performs exactly as you envisioned.

What is the foil printing process?

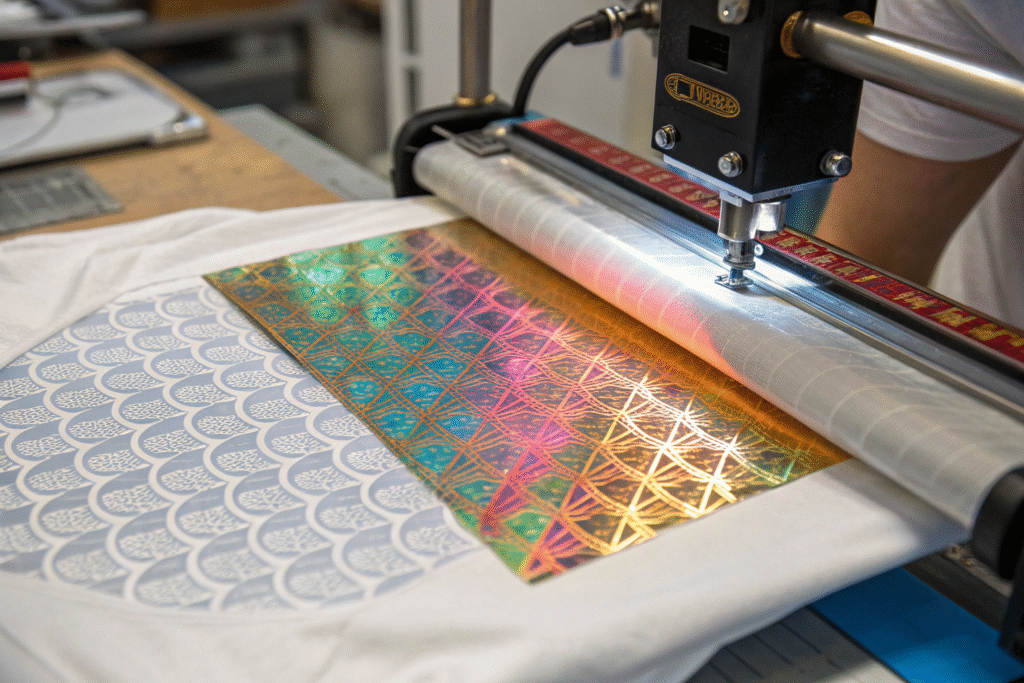

Foil printing, often called hot foil stamping, is like applying a temporary tattoo to fabric but with heat and pressure. It's a decorative technique. The goal is to create specific, eye-catching metallic or holographic patterns on the surface of the fabric. This process is ideal for adding logos, intricate designs, or seasonal flair to garments.

The foil printing process starts with a custom design, often created digitally. This design is then used to make a metal die or a special screen. A thin, carrier film is coated with a release layer and a metallic or pigment layer. This is the foil roll you can see and touch. The fabric is placed under the machine, and the foil is laid on top. The heated die or press then applies significant pressure. The heat and pressure activate the release layer, causing the metallic design to transfer only from the carrier film to the specific areas of the fabric. The unused foil is then peeled away, revealing the shiny design stuck to the textile.

How does heat transfer foil printing work?

The magic of heat transfer foil printing relies on three key elements: heat, pressure, and adhesion. First, the fabric must be prepared; it often needs a good surface energy to accept the foil. The machine heats the metal die to a precise temperature, typically between 100°C and 150°C. When the die presses the foil onto the fabric, the heat melts the adhesive layer on the foil. The pressure ensures full contact, forcing the metallic layer to bond with the fabric fibers. Once the press lifts, the foil cools almost instantly. The carrier film is then rolled away. The areas that were contacted by the heated die now have a permanent, shiny design. This method is excellent for achieving high detail on materials like polyester or nylon.

What are the visual effects of foil printing?

The visual effects of foil printing are primarily about creating a premium, decorative look. You can achieve a wide range of finishes beyond standard gold and silver. Holographic foils, patterned foils, and even matte pigment foils are all possible. The result is a design that sits on the surface of the fabric. It has a distinct metallic sheen and a slightly raised, tactile feel. However, this aesthetic comes with a functional trade-off. The foil layer can crack or peel over time with repeated washing and flexing. Its durability is less than that of the base fabric itself, making it better for fashion items rather than high-abrasion technical gear.

What is the fabric lamination process?

Fabric lamination is a completely different beast. It's a manufacturing process that permanently bonds two or more separate layers together to create a new, composite material. Think of it as making a fabric sandwich. The goal is functional, not just decorative. Lamination is used to give fabrics new properties they didn't have before, such as becoming completely waterproof, windproof, or breathable.

The lamination process involves three main components: the outer shell fabric, a membrane film (like TPU or ePTFE), and an inner lining or scrim. These layers are fused using heat, pressure, and adhesives. The outer fabric provides durability and the final look. The membrane in the middle is the magic layer—it has microscopic pores that block liquid water but allow water vapor (sweat) to escape. The inner scrim protects the delicate membrane. At our partner factories, we use large calender machines that roll these layers together under controlled heat and tension, creating a permanent, high-performance bond.

How is a waterproof membrane laminated to fabric?

The lamination of a waterproof breathable membrane is a precision engineering task. The most common method is hot-melt lamination. First, the membrane, often made of Thermoplastic Polyurethane (TPU), is heated until its surface becomes tacky. It is then immediately pressed between the outer shell fabric and the inner lining fabric. The machine applies uniform pressure across the entire width of the fabric roll as it passes through heated rollers. This process ensures no air bubbles or delamination points. The result is a unified, three-layer fabric (3L) that is robust and reliable. This is the technology behind trusted performance brands and is essential for outdoor apparel designed for harsh conditions.

What are the functional benefits of lamination?

The benefits of lamination are all about enhancing performance and protection.

- Weather Protection: It creates an impenetrable barrier against rain, snow, and wind.

- Breathability: High-quality laminated fabrics allow body moisture to escape, keeping the wearer dry from the inside.

- Durability: The bonded structure often increases the fabric's tear strength and overall ruggedness.

- Lightweight: A laminated fabric can achieve high weather protection without the bulk of traditional coated fabrics.

The main drawback is that the hand feel can be stiffer. Also, if the lamination is poor quality, the layers can separate, a problem known as delamination.

Foil Print vs. Lamination: A Detailed Comparison

Choosing between foil print and lamination is not about which is better, but which is right for the job. They serve different masters: one serves aesthetics, the other serves function. A direct comparison makes their distinctions clear. Let's break it down to help you make a data-driven decision for your specific product.

The core difference is in the application and result. Foil print is a localized, surface-level aesthetic enhancement. Lamination is a full-coverage, structural transformation for performance. If you want a shiny logo on a party dress, choose foil print. If you need a jacket to survive a mountain storm, choose lamination.

How do cost and production time compare?

For most projects, foil printing is more cost-effective for short to medium runs, especially for complex designs. Setting up a lamination line involves a much higher initial investment and is more efficient for large, continuous rolls of fabric.

| Feature | Foil Printing | Fabric Lamination |

|---|---|---|

| Primary Goal | Decorative, Aesthetic | Functional, Performance |

| Process | Selective, Heat Transfer | Full-Coverage, Bonding |

| Hand Feel | Can be slightly stiff on the design | Overall fabric is stiffer |

| Durability | Moderate (can crack with wear) | High (if quality is controlled) |

| Best For | Fashion, Sportswear Logos, Promo | Outdoor Gear, Medical, Workwear |

| Breathability | Largely unchanged | Can be engineered to be highly breathable |

| Cost for Small Batch | Lower | Higher |

Which is more durable and long-lasting?

When it comes to pure durability and longevity, a well-executed lamination is the clear winner. The bond in lamination is a full-scale molecular adhesion between layers, designed to last the lifetime of the garment. It can withstand abrasion, repeated washing, and harsh environmental conditions. Foil printing, while permanent under normal circumstances, is more vulnerable. The metallic layer can crack along crease lines or peel at the edges after aggressive washing or heavy use. Therefore, for technical apparel or items requiring a long service life, lamination is the more reliable choice. Foil printing is perfect for fashion items where visual impact is more critical than long-term mechanical resilience.

How to choose between foil and lamination?

Making the final choice boils down to asking the right questions about your product. There is no one-size-fits-all answer. The best choice depends entirely on the end use of your garment and the experience you want to deliver to your customer. A misstep here can lead to product failure and unhappy customers.

Start with the core question: Is the primary need visual appeal or environmental protection? If the answer is visual appeal, you are in foil printing territory. If it's protection from rain, wind, or other elements, you are looking at lamination.

What questions should you ask your supplier?

To ensure quality and avoid surprises, you must vet your supplier thoroughly. Don't just ask about price; ask about their technical capabilities and quality control.

- For Foil Printing: "Can you provide a wash test report showing the colorfastness and adhesion of the foil after 20+ home washes?" and "What is the minimum order quantity for a custom foil color?"

- For Lamination: "What is the hydrostatic head rating and moisture vapor transfer rate (MVTR) of your standard laminated fabric?" and "Can you guarantee against delamination, and what is your testing protocol for this?"

Pushing for these details separates amateur suppliers from professional partners like us, who have a CNAS-certified lab on-site to provide all this data upfront.

What are the common mistakes to avoid?

The biggest mistake is choosing a technique based on looks alone without considering performance. I've seen designers choose a beautiful foil print for a ski jacket logo, only to have it crack in the cold. Another common error is not requesting a hands-on sample. Always get a physical swatch. Feel the hand, test the drape, and if possible, wash it yourself. For lamination, a key mistake is ignoring breathability. A fully waterproof fabric that doesn't breathe will make the wearer wet from their own sweat. Finally, failing to discuss the entire supply chain, from fabric inspection to final packaging, can lead to delays and quality issues. Ensure your supplier has integrated control over each step.

Conclusion

Understanding the fundamental difference between foil printing and lamination is crucial for any brand developing apparel. Foil printing is your go-to for adding dazzling, metallic aesthetics and creating standout fashion pieces. Lamination is the essential process for building high-performance, protective gear that shields the wearer from the elements. One creates a visual statement; the other builds a functional shield. By matching the technique to your product's core purpose, you ensure customer satisfaction and brand integrity.

Your design vision deserves the right technical execution. If you are developing a new clothing line and need expert guidance on which finishing technique—or any other process from yarn sourcing to final QC—is best for your order, let's talk. Our team, with over 20 years of experience in the heart of the Keqiao textile district, is ready to help you navigate these choices. For a direct conversation on how we can partner to bring your ideas to life with quality and efficiency, please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com. We are here to co-create value with you.