As a fabric manufacturer with over two decades in the textile hub of Keqiao, I often hear this question. Many of our international clients, especially those sourcing from Asia, are curious about this fundamental material. Greige fabric, sometimes called grey or loom-state fabric, is the unsung hero of the textile world. It is the raw, unfinished cloth straight off the weaving or knitting loom. It hasn't been bleached, dyed, or treated in any way. Understanding greige goods is crucial for anyone involved in apparel production, as it forms the essential canvas upon which all other textile magic is performed.

Greige fabric is the raw, unbleached, and undyed textile material directly after weaving or knitting, serving as the foundational base for most finished fabrics in the global supply chain. It is the critical first step in transforming fibers into the textiles we use every day. For buyers, controlling the quality at the greige stage is one of the most effective ways to ensure the final product's performance and cost-efficiency.

Let's pull back the curtain on this essential component. Knowing about greige fabric can transform your sourcing strategy, giving you greater control over quality, cost, and lead times. This knowledge is power in our fast-paced industry.

What are the main types of greige fabric?

Greige fabric comes in many forms, just like finished textiles. The two primary categories are woven and knitted greige goods. Woven greige, like raw canvas or denim, is strong and structured. Knitted greige, like the plain jersey used for T-shirts, is soft and stretchy. The type of fiber used also defines the greige fabric. You will find cotton greige, polyester greige, and various blends, each with distinct properties even in this raw state. Recognizing these types helps buyers select the right base material for their specific end-use, whether for durable workwear or comfortable casual apparel.

How does woven greige differ from knitted greige?

The core difference lies in their construction. Woven greige fabric is made by interlacing two sets of yarns (warp and weft) at right angles, much like a basket weave. This creates a stable, less stretchy material ideal for shirts, trousers, and denim. At our Fumao weaving facility, we produce massive rolls of woven greige like poplin and twill. Knitted greige, conversely, is made from a single yarn interlooped in a series of connected chains. This structure gives it inherent stretch and drape, making it perfect for T-shirts, sweatshirts, and intimate apparel. The choice between them depends entirely on the desired characteristics of the final garment. For a deeper dive into textile constructions, the Textile Institute provides excellent resources, and understanding fabric weight is a key next step.

Why is fiber content crucial in greige goods?

The raw fiber determines the greige fabric's fundamental personality. Cotton greige is highly absorbent, breathable, and a joy to dye, which is why it's a staple in our stock. Polyester greige is strong, resistant to wrinkles and shrinkage, and dries quickly. A greige fabric made from a cotton-polyester blend aims to offer the best of both worlds. The fiber content dictates how the fabric will react to subsequent dyeing, printing, and finishing processes. For instance, achieving vibrant colors is often easier on natural fiber greige like cotton. Our CNAS-certified lab rigorously tests our greige goods to ensure fiber composition is exactly as specified, guaranteeing consistent results for our clients throughout the finishing pipeline.

Why is greige fabric so important for global buyers?

For serious buyers, engaging at the greige fabric stage is a strategic move. It offers unparalleled control over the entire production process. You are not just buying a finished fabric; you are commissioning a custom product from its very foundation. This allows for significant cost savings, as you bypass intermediate markups. More importantly, it allows you to dictate the exact finishing treatments—dyeing, printing, coating—to meet your specific quality and functional needs. In an era of volatile logistics, securing greige goods early can de-risk your supply chain against delays in finished fabric production.

How can sourcing greige fabric reduce costs?

Sourcing at the greige stage eliminates multiple handling and transaction layers. You are dealing directly with the mill, which often results in a lower price per meter. Furthermore, you gain flexibility. By controlling the finishing stage, you can choose local or specialized partners for dyeing and printing, potentially optimizing costs and lead times based on your order. Bulk purchasing of greige fabric also leads to economies of scale. For example, our clients who order large quantities of organic cotton greige benefit from our mill-direct pricing and our integrated partnerships with GOTS-certified dyers, streamlining their path to a sustainable final product.

What are the quality control advantages?

Inspecting fabric at the greige stage is your first and best defense against defects. Issues like slubs, yarn variations, or weaving imperfections are visible and can be addressed before additional value is added through costly dyeing and finishing. Catching a flaw at this point saves immense time and money. At Fumao, our dedicated QC team performs 100% inspection on all greige goods leaving our weaving factory. We use advanced QR code tracking to log every roll's data, providing you with real-time access to its quality status. This proactive approach guarantees that only pristine material moves to the next stage, ensuring a 98% client pass rate on final inspections.

How is greige fabric integrated into a full-service supply chain?

A full-service supplier like Fumao turns greige fabric from a commodity into a tailored solution. We don't just sell you the raw cloth; we manage its entire journey. Our model is vertically integrated, meaning we control or have deep partnerships across every step: from our own large-scale weaving, to cooperative dyeing and printing factories, all the way to coating, inspection, and packaging. This creates a seamless, efficient pipeline where the greige fabric is transformed according to your exact tech packs, with consistent quality oversight from start to finish.

What does an end-to-end production flow look like?

The journey begins with your order and our raw material sourcing. We then produce the greige fabric in our weaving factory. Once inspected and approved, the greige rolls are transported to our partner dyeing factory for coloration or bleaching. They might then move to our embroidery or printing units for design application. For functional apparel, the fabric could be sent to our coating factory for a water-resistant layer. Finally, it undergoes a final inspection, is packaged by our dedicated team, and is prepared for shipping. This integrated flow, managed under one roof, drastically reduces coordination headaches and ensures timely delivery, a critical factor for brands competing in fast fashion.

How does this integration benefit timeliness and logistics?

Integration is the key to speed and reliability. With all processes coordinated internally, we eliminate the delays that occur when multiple independent suppliers hand off materials. Our AI-driven trend analysis helps us anticipate demand for certain greige fabrics, allowing us to keep strategic stock. This enables our famous 48-hour sample development. For bulk orders, our control over the chain allows for "quickly bulk delivery." Furthermore, being located in Keqiao, we have direct access to the city's multimodal logistics hubs, ensuring your finished fabric, which started as greige goods, reaches the port and your doorstep efficiently.

What should you look for in a greige fabric supplier?

Choosing the right greige fabric partner is a critical business decision. You need more than just a seller; you need a solutions provider with proven expertise and reliability. Key factors include the supplier's manufacturing capability, quality control systems, communication transparency, and financial stability. The ideal partner should have a strong physical footprint, like our own weaving factory and cooperative network, and a track record of serving international clients with complex demands. They must understand not just fabric, but the entire global supply chain.

Why are certifications and testing vital?

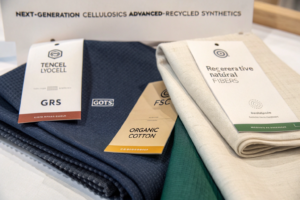

Certifications are your independent verification of a supplier's claims. For greige fabric, look for a supplier with a CNAS-accredited lab, like ours, which validates their internal testing capabilities. This ensures that fundamental checks on fiber content, yarn count, and fabric density are accurate. Certifications like OEKO-TEX or GOTS for organic fibers at the greige stage provide confidence in the material's safety and sustainability from the very beginning. These documents are not just paperwork; they are a promise of quality and responsibility, mitigating your risk and protecting your brand's reputation.

How does supplier location impact efficiency?

Location within a robust textile ecosystem like Keqiao, China, offers an unbeatable advantage. We are at the heart of the world's largest textile cluster. This gives us immediate access to raw materials, specialized labor, and a dense network of finishing partners. This proximity drastically shortens transit times between production stages. A dyeing factory might be just down the road from our weaving mill. This localized efficiency, combined with Keqiao's "Silk Road" initiatives for streamlined export and customs clearance, creates a frictionless pipeline from greige fabric to shipped finished product, insulating you from many common logistical delays.

Conclusion

Greige fabric is far more than just unfinished cloth; it is the foundational building block of the textile industry. Understanding its types, its strategic importance for cost and quality control, and its role in an integrated supply chain empowers you as a buyer. By engaging with a capable and full-service supplier at the greige stage, you gain unprecedented oversight, flexibility, and efficiency in your sourcing process. This proactive approach is what separates successful, resilient brands from the rest. It allows you to build quality and value into your products from the very beginning.

If you are looking to co-create value and have greater control over your fabric sourcing, let's talk. We at Fumao Fabric are ready to be your strategic partner in Asia. For a direct conversation about how we can produce your clothing orders starting from the highest quality greige fabric, please contact our Business Director, Elaine. She will ensure you get the professional service and dedicated attention your business deserves. Reach out to Elaine at: elaine@fumaoclothing.com.