As a fabric supplier with over two decades in the textile hub of Keqiao, I get this question a lot. Brand owners and designers often wonder about the key differences between these two classic shirting fabrics. Both are incredibly popular, but they serve slightly different purposes in your collection.

Poplin and broadcloth are both plain weave fabrics primarily used for shirts. Poplin is defined by its distinctive ribbed texture, resulting from finer warp yarns and thicker weft yarns. Broadcloth, in contrast, is a tightly woven, very smooth fabric with a simple, flat appearance. The choice between them hinges on the desired weight, texture, and drape for the final garment.

Understanding these fabrics is crucial for making the right sourcing decision. A misstep here can affect the comfort, durability, and overall feel of your shirts. Let's dive into the details to ensure your next order is a perfect fit for your market.

What is the main difference in their weave?

The core difference lies in the yarn structure and the resulting texture. This fundamental distinction impacts everything from the fabric's handfeel to its performance.

Poplin uses a plain weave but with a specific yarn combination. It typically features warp yarns that are much finer than the weft yarns. This difference in yarn thickness creates a subtle, crisp ribbed effect across the surface of the fabric. You can both see and feel this gentle corded texture. Broadcloth also uses a plain weave, but it is woven in a much tighter manner with yarns of a similar thickness. This high thread count and tight weave result in a fabric that is exceptionally smooth, flat, and has a very soft hand.

How does the weave affect fabric durability?

The weave structure directly influences how the fabric withstands daily wear and tear. Poplin's ribbed structure, often made with stronger yarns, provides excellent durability. The slightly thicker crosswise yarns add to its resistance against abrasion, making it a robust choice for shirts that require frequent washing and wearing. Its construction prevents it from snagging easily. For high-performance needs, some poplins are even made with blended yarns like cotton-polyester for enhanced strength.

Broadcloth's durability comes from its density. The tight plain weave creates a very compact fabric that is resistant to pulling and tearing. However, because it is often made with very fine yarns to achieve its softness, it can be slightly less resistant to abrasion than a standard poplin. Its strength is in its tight construction. At Fumao, our CNAS-accredited lab tests both fabrics for tear and tensile strength, ensuring they meet the quality standards demanded by major brands.

Which weave is better for print designs?

This is a critical question for fashion brands. Broadcloth's flawlessly smooth surface makes it an ideal canvas for detailed prints. The lack of texture allows the ink to sit evenly, resulting in sharp and vibrant patterns. This is why it's a top choice for custom printed shirts and detailed graphic tees. Poplin's characteristic rib can sometimes interfere with the finest details of a print, creating a slightly textured effect on the design. However, this can be a desirable stylistic choice for certain looks. Our printing partners offer both reactive printing and pigment printing to ensure colorfastness on either fabric.

How do poplin and broadcloth feel to wear?

The "handfeel" or how the fabric feels against the skin is a major factor in customer satisfaction. This is determined by the weave, the fiber used, and the finishing techniques.

Poplin has a crisp, cool, and lightweight feel. Its structure allows for good air circulation, making it very breathable. The slight texture gives it a dry hand, which many people find comfortable. Broadcloth feels incredibly soft, smooth, and silky. Its high thread count and tight weave create a fluid drape that clings softly to the body, offering a luxurious sensation.

Which fabric is more breathable?

Breathability is key for comfort, especially in warm climates or for formal wear. Poplin is generally more breathable. The simple plain weave, combined with the slight texture, allows air to pass through the fabric more easily. When made from natural fibers like organic cotton or linen blends, poplin becomes an excellent choice for summer shirts and tropical business attire. Broadcloth, due to its very tight weave, can be less breathable than poplin. However, when woven from high-quality long-staple cotton, it still offers respectable comfort.

Are they both suitable for sensitive skin?

For customers with sensitive skin, the fiber content is as important as the weave. Both fabrics can be suitable if made from the right materials. Broadcloth, with its ultra-soft finish, is often a great choice. However, some broadcloth may be treated with chemical softeners to achieve that feel. We always recommend opting for fabrics with Oeko-Tex certification, which guarantees they are free from harmful substances. Poplin made from natural Bamboo Silk (BAMSILK) or Tencel™ is also exceptionally soft and hypoallergenic, making it perfect for sensitive skin and children's wear.

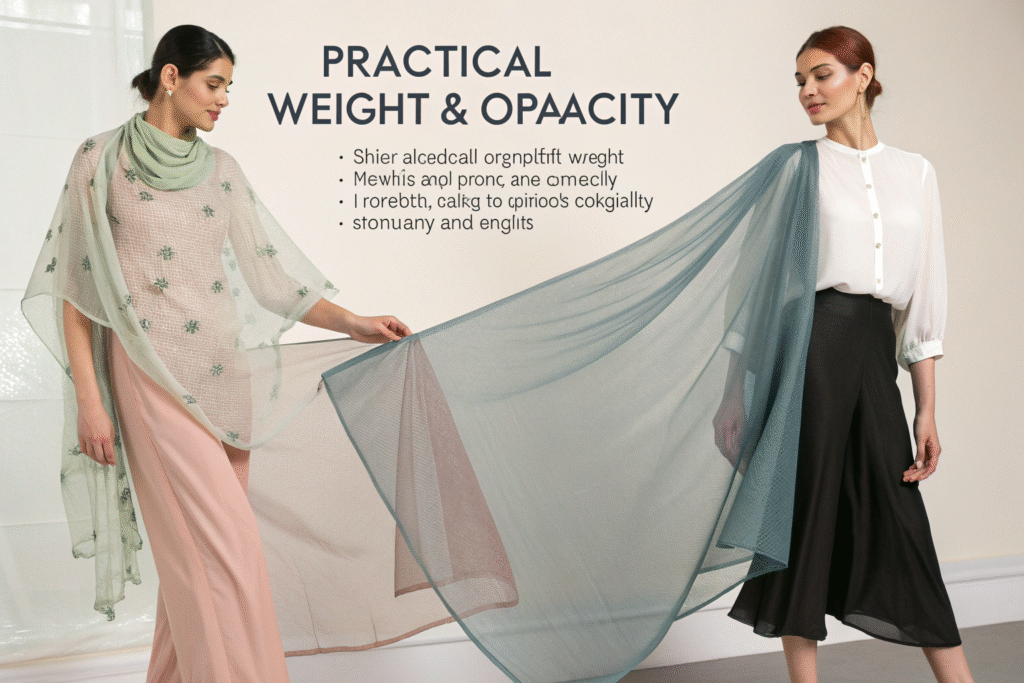

Which fabric is heavier and more opaque?

Weight and opacity are practical considerations for modesty and seasonality. Designers need to know what lies underneath the fabric.

Typically, broadcloth is lighter in weight than poplin. It is often woven into lighter weights (e.g., 80-100 gsm), which can make it slightly sheer, especially in lighter colors. Poplin is commonly found in medium weights (e.g., 100-130 gsm), giving it more substance and better opacity. This makes poplin a more versatile choice for corporate shirts where opacity is essential.

| Fabric | Typical Weight (GSM) | Opacity Level | Best For |

|---|---|---|---|

| Poplin | 100 - 130+ | High (Excellent) | Business shirts, uniforms, daily wear |

| Broadcloth | 80 - 100 | Medium (Can be sheer in light colors) | Luxury dress shirts, printed shirts, blouses |

How does fiber content affect the weight?

The base fiber plays a huge role. A 100% cotton poplin will have a substantive weight and crisp drape. However, the same poplin weave in a linen blend will be lighter and have a more relaxed, textured drape. Similarly, a broadcloth made from Egyptian cotton will be luxuriously soft and dense, while a broadcloth made with a polyester blend might be lighter and more wrinkle-resistant but less breathable. We help clients select the perfect fiber-weave combination for their specific design vision.

Can you get heavy-weight broadcloth?

While less common, it is possible to produce heavier broadcloth by using thicker yarns. However, this often changes its fundamental characteristic of being a soft, smooth, and lightweight fabric. At this point, it may start to resemble a poplin or a different fabric category like voile. For clients seeking a heavier, opaque shirting fabric, we usually steer them towards our standard poplin or even a twill weave fabric, which offers excellent durability and a distinct diagonal texture.

Poplin vs Broadcloth: Which is right for my brand?

The final decision depends on your brand's aesthetic, target price point, and the intended use of the shirts.

Choose Poplin if your brand focuses on durability, a crisp appearance, and all-season versatility. It's perfect for corporate uniforms, everyday business shirts, and brands that value a classic, structured look. Its robustness also makes it a favorite for school uniforms and workwear. Choose Broadcloth if your brand emphasizes luxury, a soft handfeel, and a sleek, modern drape. It is ideal for high-end dress shirts, fashion-forward blouses, and garments where detailed printing is a key selling point.

How do I source the right quality?

Sourcing the right quality starts with clear communication with your supplier. Specify the fiber content, weight (in GSM), and finish you desire. Always request physical fabric swatches before placing a bulk order. At Fumao, we provide 48-hour sample development, allowing you to feel the handfeel and test the properties yourself. Our end-to-end quality control ensures that the bulk fabric you receive perfectly matches the approved sample in weight, color, and texture.

What about cost and lead times?

Generally, the cost is more influenced by the fiber used (e.g., organic cotton vs. standard cotton) than the weave itself. A luxury Egyptian cotton broadcloth will cost more than a basic polyester-cotton poplin. For standard qualities of similar fiber, the price is often comparable. Lead times are determined by the production volume and customization. Our integrated supply chain in Keqiao allows for quick bulk delivery. We leverage local dyeing and weaving partnerships to accelerate production, ensuring you get your fabrics on time, every time.

Conclusion

Understanding the distinct characteristics of poplin and broadcloth is essential for making an informed decision for your clothing line. Poplin offers a durable, crisp, and breathable option with a classic ribbed texture. Broadcloth provides a ultra-soft, smooth, and luxurious feel with a perfect surface for printing. Your choice will ultimately define the comfort, style, and quality of your finished shirts.

If you are ready to move forward with developing your own shirting line, we are here to support you with our full-service capabilities, from yarn sourcing to final packaging and shipping. For a personalized consultation and to discuss your specific fabric needs, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's co-create the perfect shirts for your brand.