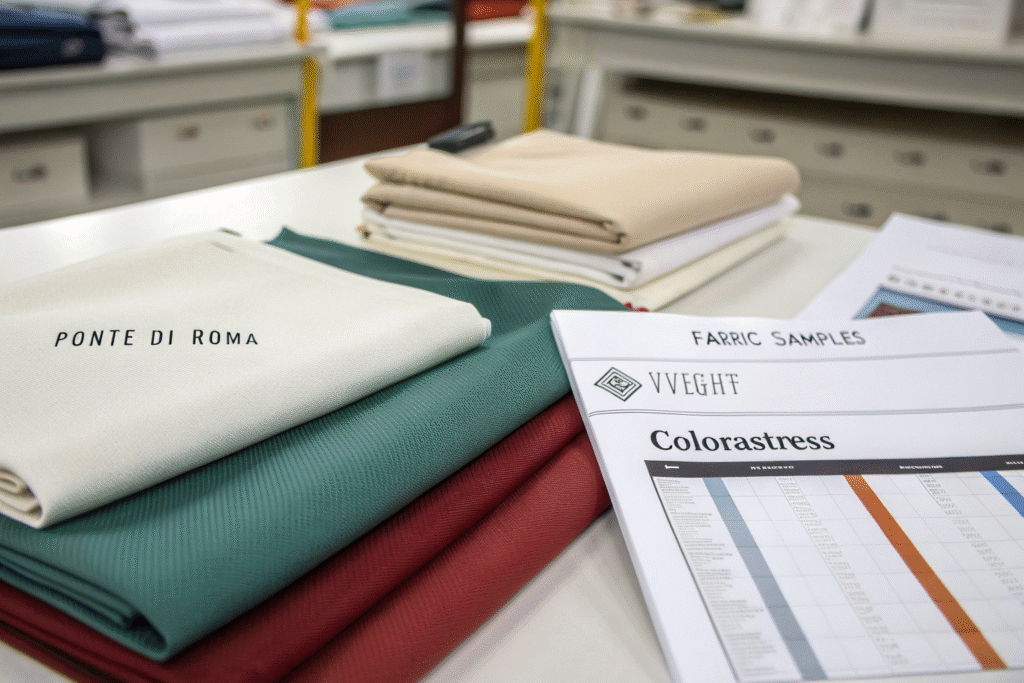

Ponte di Roma. The name itself sounds sophisticated, perhaps even intimidating if you're not a fabric connoisseur. You might have seen this fabric listed on a technical sheet, felt it in a high-end garment, or heard designers praise its versatility. But what exactly is it? More importantly, if you're sourcing fabrics for your next clothing line, why should you care about this specific double knit? Many buyers and brands face the challenge of finding a fabric that perfectly balances comfort, structure, and a premium feel without compromising on durability. They struggle with knits that are too flimsy or wovens that are too restrictive. This is where understanding ponte di Roma becomes a strategic advantage.

Simply put, ponte di Roma (often called ponte knit or double knit) is a robust, stable, and versatile type of double-knit fabric, renowned for its excellent recovery, smooth surface, and comfortable stretch. It is the go-to choice for creating structured yet comfortable garments that need to hold their shape beautifully. This article will demystify ponte di Roma, exploring its unique structure, key characteristics, and the vast range of applications that make it a favorite from the runway to retail. We will also compare it to similar fabrics and provide practical sourcing tips to ensure you get the highest quality material for your production needs. By the end, you'll see why this fabric is a workhorse for discerning brands and how it can solve common design and production challenges.

Understanding the properties of ponte di Roma is key to unlocking its potential. Let's dive into what makes this fabric so special and widely used in the fashion industry.

Defining Characteristics of Ponte di Roma Fabric

Ponte di Roma stands out in the world of knits due to its unique construction and performance. When you're evaluating fabrics for your collection, its specific traits offer solutions to common problems like sagging, poor durability, and an unprofessional look. The moment you feel a piece of ponte di Roma, you notice its substantial weight and smooth hand-feel. It’s noticeably heavier and more stable than a single jersey, yet it provides comfortable, multi-directional stretch that wovens cannot. This combination is no accident; it's the direct result of its double-knit construction. For buyers, this translates into garments that look expensive, feel comfortable, and withstand the test of time and wear.

The most defining characteristic of ponte di Roma is its double-knit structure. Unlike single knits which are prone to curling at the edges and can be flimsy, ponte di Roma is created using a specific interlock knitting technique. This process essentially involves two sets of needles creating two layers of fabric that are interlocked back-to-back. This results in a fabric that is the same on both sides, with no distinct right or wrong side, making it easier to work with during the garment manufacturing process. This construction is what gives the fabric its signature stability and prevents it from curling, a significant advantage in cutting and sewing.

How Does Its Double-Knit Structure Enhance Durability?

The double-knit structure is the engine behind the fabric's renowned durability. Because it comprises two interlocked layers, it is far more resistant to runs and snags compared to single knits. This inherent strength means garments made from ponte di Roma can maintain their integrity even with frequent wear and washing. The density of the knit also contributes to its ability to hold its shape exceptionally well. While a simple jersey knit might stretch out over the day, especially at the knees or elbows, a ponte di Roma garment will snap back to its original form. This excellent recovery reduces the problem of garment distortion, a common pain point for brands focused on quality and customer satisfaction. Furthermore, this durability makes it a suitable choice for uniforms and tailored items that require a crisp appearance throughout the day.

Why is Its Weight and Stretch So Important for Designers?

The medium to heavy weight of ponte di Roma provides the structure that designers often seek for tailored pieces. It has enough body to create clean lines and defined silhouettes for items like blazers, skirts, and dresses. This structure allows it to drape elegantly without clinging uncomfortably to the body. Simultaneously, its balanced two-way or four-way stretch offers freedom of movement that rigid wovens cannot. This is crucial for the modern consumer who prioritizes both style and comfort. The stretch also makes ponte di Roma more forgiving in terms of sizing, which can help reduce returns for brands. When blended with fibers like spandex (also known as elastane), the fabric gains even better recovery and flexibility, enhancing comfort without sacrificing its structured look. This perfect balance makes it ideal for creating "elevated basics" that are both stylish and practical.

What Are the Most Common Applications of Ponte di Roma?

Ponte di Roma's unique blend of structure and stretch opens up a world of possibilities for garment design. Its applications range from sophisticated workwear to comfortable travel attire, making it an incredibly versatile choice for any fashion brand's lineup. For a brand owner or designer, using ponte di Roma means you can create pieces that are perceived as high-value by customers. They see the structure and assume quality, while they feel the stretch and experience comfort. This positive perception directly impacts brand reputation and customer loyalty. From our experience supplying to brands in the US and EU, garments made from high-quality ponte di Roma consistently receive positive feedback for their fit and longevity.

The most common and iconic use of ponte di Roma is in structured women's wear. Think of the perfect pencil skirt that hugs curves without restricting movement, or a tailored dress that looks sharp from morning to evening without wrinkling. Its ability to hold complex shapes makes it a favorite for fitted jackets and blazers that offer a more comfortable alternative to traditional woven suiting. Beyond these, its durability makes it an excellent choice for uniforms in sectors like hospitality and aviation, where a professional appearance and long-lasting wear are essential.

How Is It Used in Women's Pants and Skirts?

In womenswear, ponte di Roma is the secret behind comfortable yet polished bottoms. For pants, it is the ideal fabric for trousers, leggings, and cigarette pants. These items benefit from the fabric's smooth surface, which is flattering and avoids the casual look of athletic knits. Skirts, especially pencil and A-line silhouettes, gain their defining shape from the body and stability of ponte di Roma. The fabric provides enough compression to be sleek without being tight, and its recovery ensures the skirt doesn't bag out after sitting for long periods. This makes it a top choice for work-appropriate attire that transitions seamlessly to after-work social events. Designers often choose ponte di Roma for these applications because it reduces the need for complex internal construction like linings, simplifying the manufacturing process and reducing costs.

What Makes It Ideal for Dresses and Jackets?

Ponte di Roma is a dream fabric for dresses and unstructured jackets. Sheath dresses and fit-and-flare designs made from this fabric are incredibly popular because they offer a sculpted look with built-in ease. The fabric drapes cleanly over the body, creating elegant lines that are hard to achieve with lighter knits. For jackets and blazers, ponte di Roma allows for the creation of "knit blazers" – a category that has exploded in popularity. These jackets provide the sharp silhouette of a traditional blazer but with the flexibility and comfort of a knit. They are less prone to wrinkling, making them perfect for travel and busy lifestyles. This versatility is why many of our clients, from fast-fashion brands to luxury labels, consistently include ponte di Roma pieces in their seasonal collections. It’s a fabric that meets the demand for multifunctional, high-performance fashion.

How Does Ponte di Roma Compare to Other Double Knits?

While "ponte di Roma" is sometimes used as a generic term for double knits, there are subtle but important distinctions between it and its relatives, such as ponte de legno and scuba knit. Understanding these differences is critical for making the right sourcing decision. Choosing the wrong type of double knit can lead to a garment that doesn't perform as expected, resulting in customer dissatisfaction. As a supplier, we help our clients navigate these nuances to select the perfect fabric for their specific design vision and price point. The key differentiators often lie in the fiber composition, weight, and the precise knitting technique used.

Ponte di Roma is characterized by its fine rib and smooth surface. It is typically made from a blend of polyester, rayon, and spandex. The rayon content often gives it a softer, more luxurious hand-feel compared to double knits made primarily from polyester. Its weight is substantial but versatile. In contrast, a fabric like ponte de legno is generally even heavier and stiffer, offering more extreme structure for coats and very heavy skirts. Scuba knit, another double knit, is known for its distinctively crisp hand and buoyant quality, often due to a different finishing process.

What is the Difference Between Ponte di Roma and Jersey Knit?

The difference is fundamental. Jersey is a single knit fabric, making it lighter, more fluid, and far more prone to curling at the edges. It lacks the inherent stability and recovery of a double knit. Here is a quick comparison:

| Feature | Ponte di Roma (Double Knit) | Jersey Knit (Single Knit) |

|---|---|---|

| Structure | Two interlocked layers, stable | Single layer, curls at edges |

| Weight | Medium to Heavy | Light to Medium |

| Drape | Structured, holds shape | Fluid, clings to the body |

| Durability | High, resistant to runs | Lower, can snag and stretch out |

| Common Uses | Blazers, pants, skirts | T-shirts, casual dresses, tops |

This table shows why ponte di Roma is chosen for structured garments, while jersey is reserved for more casual, lightweight applications. For brands, this means ponte di Roma elevates the perceived value of a garment significantly.

How Does It Differ from Other Stable Knits Like Scuba?

Ponte di Roma and scuba knit are both stable double knits, but they have different textures and performances. Scuba knit typically has a slightly spongier texture and a more pronounced, crisp hand. It is often made with a higher polyester content and may have a unique finish that gives it its namesake buoyancy. Ponte di Roma, on the other hand, is prized for its smoother, finer surface and excellent drape. It feels more like a traditional woven fabric but with the benefit of stretch. While scuba is great for architectural designs that need to hold a rigid shape, ponte di Roma is better for tailored, body-skimming garments that require elegance and comfort. Understanding these subtleties ensures that the fabric aligns with the design specifications and desired customer experience.

What Should You Consider When Sourcing Ponte di Roma?

Sourcing high-quality ponte di Roma is crucial for the success of your final product. Not all ponte is created equal. As a buyer, your focus should be on the fabric's composition, weight, and colorfastness, but also on the supplier's ability to ensure consistency and provide necessary certifications. At our company, we've seen how cutting corners on fabric quality can lead to production delays, garment failures, and unhappy customers. Your sourcing strategy should directly address common pain points like inconsistent dyeing, poor colorfastness, and unreliable delivery schedules. Partnering with a supplier that controls the supply chain from yarn to finished fabric mitigates these risks significantly.

The first thing to consider is the fiber composition. A typical high-quality ponte di Roma blend might be 55% polyester, 40% rayon, and 5% spandex. The polyester provides strength and durability, the rayon adds a soft, absorbent, and drapable quality, and the spandex delivers the essential stretch and recovery. The percentage of each component will affect the hand-feel, weight, and performance. Secondly, the weight of the fabric, usually measured in GSM (grams per square meter), must align with your design intent. A heavier GSM (e.g., 350-450) is ideal for winter pants and jackets, while a lighter GSM (e.g., 250-320) works better for dresses and lighter-weight separates.

Why Are Composition and Weight Critical for Quality?

The composition directly impacts the garment's performance and customer satisfaction. A higher rayon content will make the fabric softer and more breathable, but it may also be more prone to shrinkage if not properly pre-shrunk during the dyeing and finishing process. A higher polyester content increases durability and wrinkle resistance but can reduce breathability. The amount of spandex is critical for recovery; too little and the garment will lose its shape. The weight (GSM) determines the drape and seasonality. A fabric that is too light will lack the structure needed for a blazer, while one that is too heavy might be uncomfortable for a fitted dress. Always request swatches and technical data sheets from your supplier to verify these specifications before placing a bulk order.

How Can You Verify Supplier Reliability and Fabric Standards?

Verifying a supplier involves checking their certifications and testing capabilities. A reliable supplier will have a CNAS-accredited lab, like ours, to test for key performance metrics such as colorfastness (to washing, rubbing, and light), dimensional stability (shrinkage), and fabric strength. They should be able to provide test reports from recognized international standards like SGS or ITS. Ask about their minimum order quantities (MOQs) and lead times to ensure they align with your production schedule. For US-based buyers concerned about tariffs, inquire if the supplier has experience shipping to other markets or if the fabric can be sourced under specific Harmonized System (HS) codes that might be more favorable. A professional supplier will be transparent about these details and help you navigate the logistics, ensuring a smooth and secure sourcing process from start to finish.

Conclusion

Ponte di Roma fabric is far more than just a type of double knit; it is a strategic solution for designers and brands seeking to create garments that masterfully blend structure, comfort, and durability. Its unique double-knit construction provides the stability of a woven with the flexibility of a knit, making it indispensable for tailored womenswear, professional uniforms, and versatile separates. By understanding its characteristics, applications, and how it compares to other fabrics, you can make informed decisions that elevate your product offerings. Crucially, sourcing from a reputable supplier who guarantees quality through strict composition control and comprehensive testing is the final step to ensuring your ponte di Roma garments meet the high expectations of today's discerning consumers.

If you are looking to develop your own high-quality clothing line using premium ponte di Roma or other fabrics, we invite you to partner with us. Our integrated supply chain, from weaving to dyeing and finishing, ensures full quality control and competitive pricing. We specialize in helping international brands navigate production and logistics efficiently. For a personal consultation on your next fabric order, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let us help you turn your designs into reality.