Have you ever wondered what gives a crisp dress shirt collar its perfect shape or a structured blazer its sharp silhouette? The secret often lies not in the main fabric, but in hidden inner layers. As a fabric manufacturer with over two decades in the textile hub of Keqiao, China, I've seen how the misuse or misunderstanding of these components can make or break a garment's quality. Many designers and brands, especially those new to sourcing from China, confuse two critical elements: interlining and interfacing. This confusion can lead to production delays, cost overruns, and final products that don't meet quality expectations. Understanding the distinct roles of these materials is a fundamental step in garment development.

Simply put, both interlining and interfacing are support materials used to reinforce and shape specific areas of a garment. However, the key difference lies in their application method and form. Interfacing is typically a woven, non-woven, or knit fabric that is fused or sewn to the main fashion fabric, becoming an inseparable part of it. Interlining, on the other hand, is often a separate layer of insulation or lining that is placed between the outer fabric and the main lining, not directly fused to the outer material. This fundamental distinction impacts everything from design flexibility to production efficiency. For buyers concerned with quality and cost, knowing which to use and when is crucial for achieving the desired outcome without unnecessary expense.

Let's demystify these essential components. Choosing the right support material is as important as selecting the main fabric. It affects the drape, durability, and overall feel of the clothing. We will explore their definitions, applications, and how to select the best option for your product line. This knowledge will empower you to communicate more effectively with your suppliers in China and Southeast Asia, ensuring your vision is perfectly executed.

What is the main difference between interlining and interfacing?

Many product developers approach us with a simple question: are interlining and interfacing the same thing? The quick answer is no, but the real-world application is where the distinction matters. The primary difference comes down to integration versus layering. Interfacing is directly attached to the main fabric, while interlining is inserted as an independent layer. This core difference dictates their function, cost, and the machinery needed for application. For buyers managing complex supply chains, this affects lead times and minimum order quantities.

Understanding this difference is the first step to avoiding costly production mistakes. Using a heavy interlining where a light interfacing is needed can result in a stiff, uncomfortable garment. Conversely, using interfacing for a coat that requires thermal insulation will fail to meet the design spec. Let's break down the defining characteristics of each.

How is interfacing defined and used?

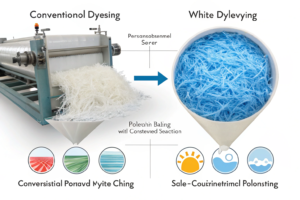

Interfacing is a support material fused or sewn to the wrong side of the main fabric to provide structure, stability, and body. It is not meant to be seen or felt as a separate layer by the wearer. Think of it as a skeleton that gives shape to specific areas like collars, cuffs, plackets, and waistbands. The most common types are fusible interfacing, which has a heat-activated adhesive on one side, and sew-in interfacing, which is stitched in place. The choice depends on the main fabric; delicate fabrics like silk might be damaged by heat, making a sew-in option better. The global fusible interlining market is a testament to its widespread use, driven by demand for efficient manufacturing. At Fumao, we often advise clients on the right interfacing weight to complement our fabrics, ensuring the integrity of the design is maintained after multiple washes.

What are the primary applications of interlining?

Interlining is generally a thicker, bulkier material used as an additional layer for warmth (like in jackets or coats), protection, or added stiffness. Unlike interfacing, it is not typically fused directly to the outer shell fabric. Instead, it is quilted or attached to the lining fabric or left as a free-hanging layer. A common example is the fluffy layer inside a winter coat, which is an interlining providing insulation. Another application is in formal wear, where a chest piece interlining is used to maintain the shape of the front panel. The key is that interlining adds properties like thermal insulation or bulk without drastically altering the hand-feel of the main fashion fabric. For brands focused on functional or seasonal apparel, selecting the right interlining is critical for performance and comfort.

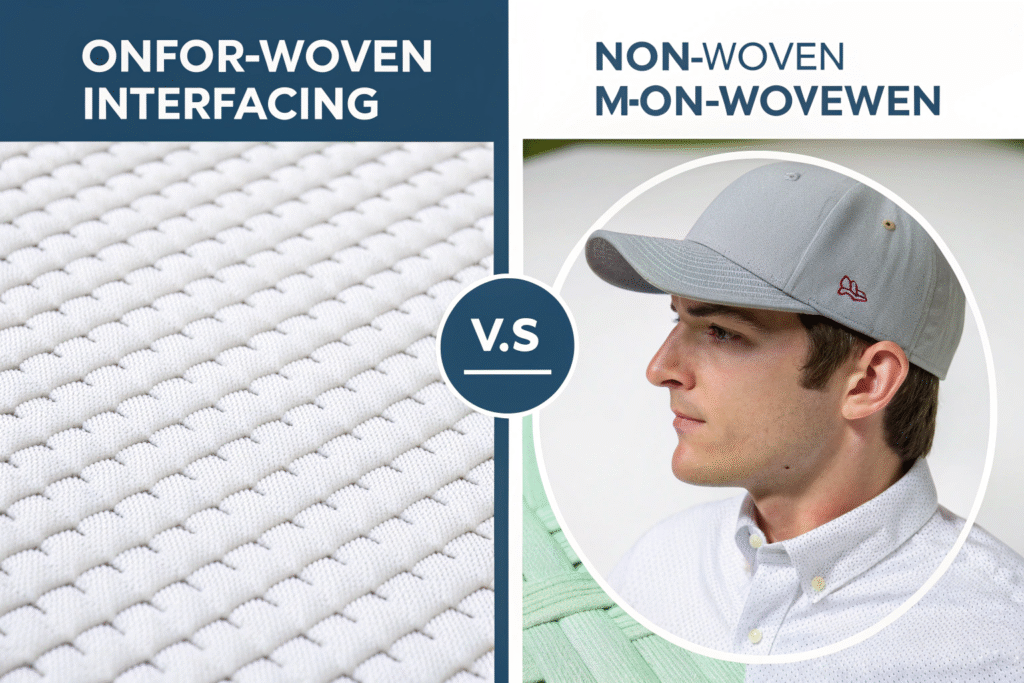

How to choose between woven and non-woven interfacing?

The choice between woven and non-woven interfacing is a common point of confusion that directly impacts the quality and cost of a garment. This decision hinges on the desired drape, durability, and the main fabric's characteristics. Woven interfacing is made from yarns interlaced at right angles, mimicking the structure of woven fabrics. It is more durable and offers a softer, more natural drape, making it ideal for structured garments like tailored shirts and blazers. However, it is generally more expensive. Non-woven interfacing is made by bonding fibers together, similar to paper. It is cost-effective and can be used for stability in areas that don't require much flexibility, like pocket openings or behind embroidery, but it can be less durable and may tear more easily.

Making the wrong choice here can lead to puckering, a stiff hand-feel, or premature wear and tear. Our CNAS-certified lab frequently tests fabric and interfacing combinations to prevent such issues for our clients. We simulate washing and wear to ensure compatibility before moving to bulk production.

When should you use woven interfacing?

Woven interfacing should be your go-to choice for high-quality garments where drape and durability are paramount. Because it has a grain line, just like your main fabric, it moves and behaves in a similar way. This is essential for areas that need shape but also some flexibility, such as the collar of a dress shirt. The bias of the woven interfacing can be used to create subtle shapes. It is also the preferred choice for natural fiber fabrics like cotton and linen, as it responds similarly to washing and wearing. While the initial cost is higher, the longevity it provides to the garment offers better value for brands focused on quality and customer satisfaction. For clients producing premium lines for markets like the EU and US, we strongly recommend investing in woven interfacing for key structural components.

What are the advantages of non-woven interfacing?

The biggest advantage of non-woven interfacing is its cost-effectiveness and ease of use. It has no grain, meaning it can be cut in any direction, reducing fabric waste and simplifying the cutting process. This leads to faster production times and lower costs. It is suitable for applications where maximum stiffness is needed without concern for drape, such as in caps, belts, or reinforcing patches. For small-batch customization or fast-fashion items where price sensitivity is high, non-woven interfacing provides a practical solution. However, it is crucial to note that low-quality non-woven interfacing can deteriorate after repeated washing. We always advise conducting thorough testing, such as checking wash fastness and shrinkage rates, before finalizing your choice for a production run.

What are the different types of fusible interlining?

Fusible interlining is the most popular type in modern garment manufacturing due to its application speed and consistent results. However, not all fusible interlinnings are created equal. They are categorized primarily by their base cloth (woven, non-woven, or knit) and the type of adhesive coating. Common adhesive types include Polyamide (PA), Polyethylene (PE), and Polyester (PES). Each has different melting points and washing resistance. For instance, PA adhesives have a low melting point and are suitable for fabrics that are sensitive to high heat, but they may not withstand high-temperature washing. PE adhesives require higher fusing temperatures but offer excellent resistance to washing and dry cleaning, making them ideal for workwear or school uniforms.

Selecting the wrong fusible interlining is a leading cause of delamination—where the interlining separates from the fabric after washing or dry cleaning. This is a critical quality failure that we help our clients avoid through rigorous testing protocols.

How does coating technology affect fusible interlining performance?

The adhesive coating technology directly determines the bond strength, flexibility, and resistance to cleaning processes. Coatings can be applied in different patterns: full coating, dot coating, or paste coating. A full coating provides a very strong bond but can make the fabric stiff. A dot coating, which is more common, offers a balance of bond strength and flexibility, preserving the fabric's natural hand-feel. The pattern affects how the adhesive penetrates the fabric during fusing. For delicate fabrics like our BAMSILK or Tencel™ blends, we recommend interlinnings with a fine, dispersed dot coating to prevent adhesive strike-through, which can create a visible stain on the right side of the fabric. The advanced coating factories we partner with use computer-controlled systems to ensure even and precise application, which is vital for maintaining the luxury appearance of high-end fabrics.

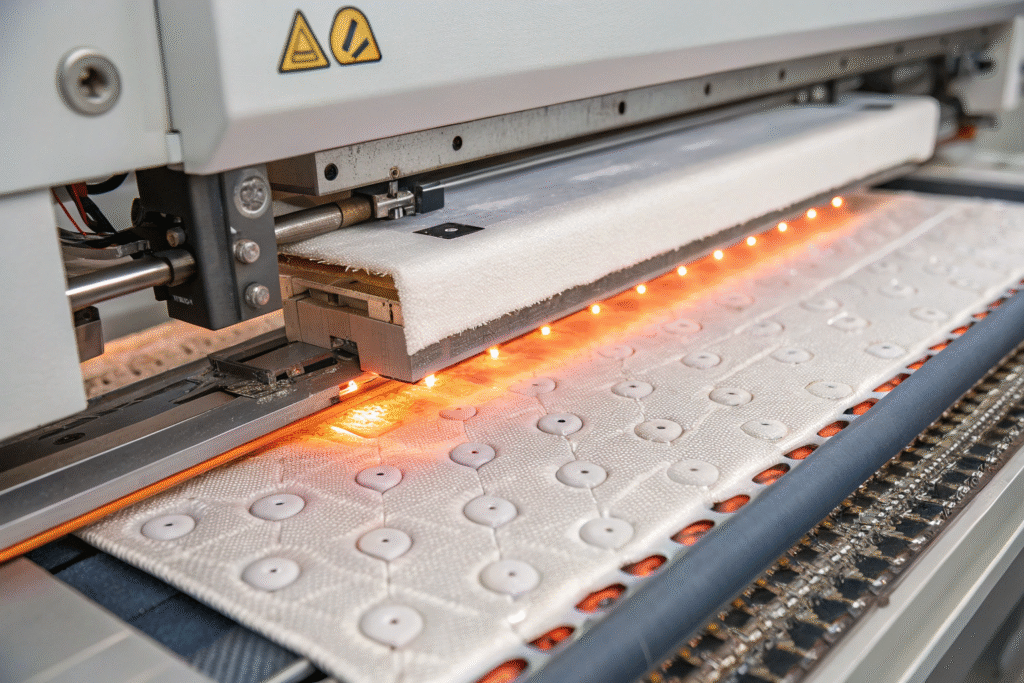

Why is fusing temperature and pressure critical?

Fusing is a science. The temperature, pressure, and time used during the fusing process must be precisely calibrated for the specific combination of main fabric and interlining. If the temperature is too low, the adhesive won't melt fully, resulting in a weak bond. If it's too high, it can damage the fabric or cause the adhesive to over-penetrate. Similarly, incorrect pressure can lead to inconsistent bonding or surface distortion. This is why a well-equipped factory with modern fusing presses is essential. We always request that our clients provide the interlining specifications so we can conduct pre-production fusing tests in our lab. This step ensures that the chosen materials are compatible with our production parameters, guaranteeing a flawless finish and preventing costly batch failures down the line.

How to source quality interlining and interfacing from China?

Sourcing these components from China, the world's textile hub, offers significant advantages in cost and variety. However, it requires diligence to ensure quality and reliability. The key is to partner with a supplier who understands your quality standards and can provide full transparency. At Fumao, we leverage our position in Keqiao to connect our clients with trusted interlining manufacturers. We act as your quality control, verifying certifications like Oeko-Tex Standard 100, which ensures the materials are free from harmful substances. We also manage the logistics, consolidating interlining with your main fabric order for streamlined shipping and customs clearance to the U.S., which helps mitigate tariff concerns.

The biggest pain point for buyers like Ron is inefficient communication leading to quality mismatches. We solve this by providing detailed tech packs and conducting sample approvals before bulk production begins.

What quality certifications should you look for?

When sourcing interlining and interfacing, never overlook certifications. The most important ones include:

| Certification | Focus Area | Importance for Buyer |

|---|---|---|

| Oeko-Tex Standard 100 | Tests for harmful substances | Ensures product safety and compliance with EU/US regulations. |

| ISO 9001 | Quality Management Systems | Indicates a reliable and consistent manufacturing process. |

| REACH (SVHC) | Regulation on chemicals | Critical for exporting to the European market. |

| UL Proponent | Flame resistance | Essential for children's sleepwear or protective clothing. |

Insisting on these certifications protects your brand and reduces the risk of rejected shipments at customs. Our quality control team includes these checks as a standard part of our fabric inspection process, giving our clients peace of mind.

How can you streamline logistics and avoid US tariffs?

A major advantage of working with a comprehensive supplier like Fumao is integrated logistics. Instead of sourcing fabric from one supplier and interlining from another, we manage the entire supply chain. We procure the interlining on your behalf, inspect it, and then coordinate with our weaving, dyeing, and finishing partners. All components are consolidated at our packaging factory before shipment. This not only reduces administrative hassle but also allows us to optimize shipping volumes and utilize our preferred freight forwarders. For U.S.-bound shipments, we have expertise in navigating trade regulations. By ensuring proper documentation and product classification, we help minimize the impact of tariffs. Our financial stability means we can handle the cash flow requirements of large orders, providing you with a secure and efficient sourcing journey from start to finish.

Conclusion

Understanding the distinct roles of interlining and interfacing is more than a technicality; it's a fundamental aspect of achieving garment quality, durability, and design intent. From defining structure with interfacing to adding functionality with interlining, each material serves a unique purpose. The choices between woven and non-woven, or different fusible types, directly impact the cost, production speed, and final feel of your product. As a partner to global brands, we see that knowledge in these areas empowers you to make better sourcing decisions, communicate effectively with manufacturers, and ultimately deliver superior apparel to your market.

We hope this guide has clarified these essential components. At Fumao Textiles International, we are more than just a fabric supplier; we are your partner in product development. Our integrated supply chain, from weaving to packaging, and our dedicated QC team, ensure that every element of your order, including the critical support materials, meets the highest standards. If you are looking to develop a new clothing line and want a reliable partner to handle the complexities of fabric and component sourcing from Asia, we are here to help.

For a professional consultation on your next project, please contact our Business Director, Elaine. She and her team will be happy to discuss your specific needs. Reach out at elaine@fumaoclothing.com.