As a garment factory owner, I talk to many American brand buyers every day. They often ask me about fabric choices. A common question is about the difference between denim and chambray. To the untrained eye, they can look very similar. Both are popular for casual shirts, dresses, and other apparel. But confusing them can lead to production mistakes and unhappy customers. Understanding their unique properties is key to designing and manufacturing the right product for your market.

While denim and chambray may appear similar at first glance, they are distinct fabrics with different weaving techniques, historical backgrounds, and functional characteristics; denim is a durable, twill-weave fabric often associated with heavier weight and diagonal ribs, whereas chambray is a lighter, plain-weave fabric known for its softness and breathability, making each suitable for different types of garments and seasons.

Choosing the correct fabric is one of the most critical decisions in apparel manufacturing. It impacts the garment's cost, comfort, durability, and overall appeal. Let's dive into the details so you can make an informed choice for your next collection.

What are the key weaving techniques: denim vs. chambray?

The most fundamental difference lies in how these fabrics are constructed. The weave determines not just the look but also the feel and performance of the fabric.

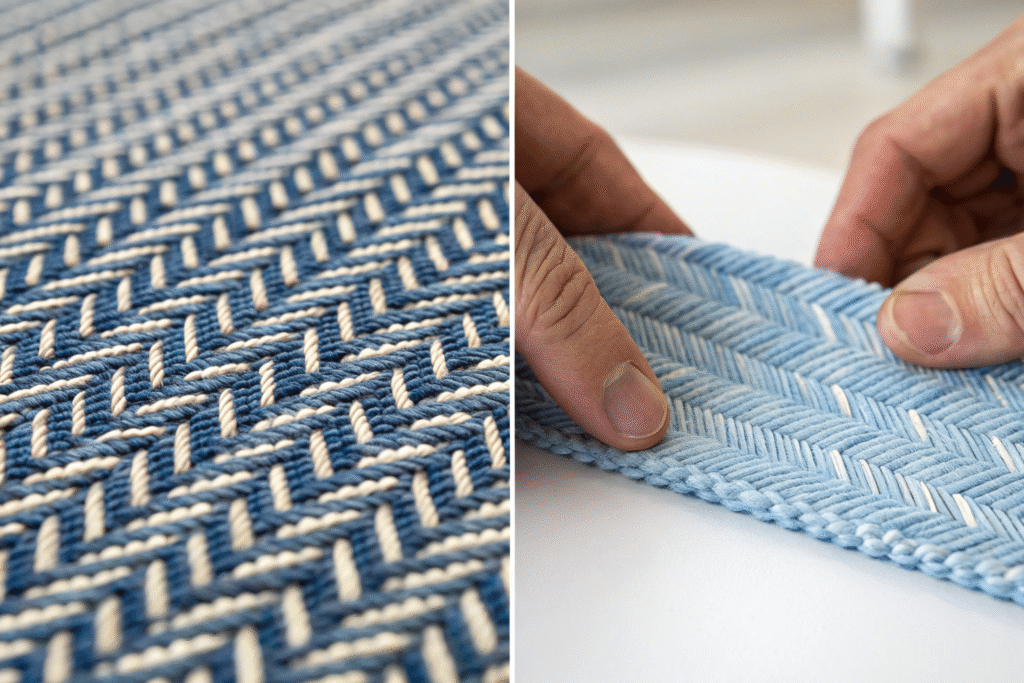

Denim uses a twill weave. In this technique, the weft thread passes under two or more warp threads in a staggered pattern. This creates the familiar diagonal ribbing on the surface of the fabric. This weave is known for its high durability and strength. It is why denim is so long-lasting. Chambray, on the other hand, uses a plain weave. This is the simplest weave. Here, the weft thread goes over one warp thread and then under the next, in a simple crisscross pattern. This results in a flatter, smoother surface compared to denim.

How does the weaving process affect the fabric's appearance?

The twill weave of denim gives it a distinctive front and back. One side is predominantly the color of the warp yarns (usually indigo), while the other side shows the color of the weft yarns (usually white). This is why the inside of blue jeans is white. The diagonal line can be subtle or pronounced. Chambray's plain weave creates a more uniform look on both sides. Because it often uses a colored warp (like light blue) and a white weft, it achieves a mottled or heathered appearance. It looks like a solid color from a distance, but up close you see the tiny white specks. This gives chambray a lighter, more casual visual texture than the rugged, solid look of traditional denim.

What are the practical implications of the weave for manufacturers?

The weave directly impacts production. Denim's twill weave is generally stronger and more resistant to tearing. This makes it ideal for workwear and heavy-use items like jeans and jackets. However, it can be stiffer initially and may require stone washing or other treatments to soften. Chambray's plain weave makes it lighter and more pliable right off the loom. It is easier to cut and sew in high-volume production lines for items like summer shirts and lightweight dresses. This simplicity can sometimes lead to faster manufacturing times compared to handling heavier denim.

How does the weight and durability of denim compare to chambray?

This is a crucial factor for brands deciding on the end-use of their garments. Weight and durability are often linked.

Denim is typically a medium to heavy-weight fabric. Its weight is measured in ounces per square yard. Standard denim for jeans can range from 10 to 14 ounces or even heavier. This substantial weight contributes to its famous durability. It can withstand a lot of wear and tear. Chambray is almost always a light to medium-weight fabric. It usually falls between 4 and 7 ounces. This makes it much lighter and more breathable than denim, but also less rugged.

Why is denim the go-to choice for heavy-duty apparel?

The combination of the twill weave and heavier yarns makes denim exceptionally tough. It is the fabric of choice for products that need to last. This includes not only jeans but also work uniforms, overalls, and jackets designed for outdoor use. Its resistance to abrasion means it won't easily develop holes from friction. For brands targeting a market that values longevity and ruggedness, denim is an unbeatable option. Its break-in period, where it softens and molds to the wearer, is part of its appeal.

In what scenarios is chambray's lighter weight an advantage?

Chambray's lighter weight is its greatest strength for specific applications. It is perfect for warm-weather clothing. Think of spring and summer collections. A chambray shirt is comfortable and breathable in ways a denim shirt cannot be. It is also ideal for children's clothing, where heavy fabric can be uncomfortable for active kids. Because it is less rigid, it offers greater freedom of movement. For brands creating layered looks or lightweight dresses, chambray provides the denim aesthetic without the associated weight and warmth.

What are the typical uses and style variations for each fabric?

Understanding the common applications helps brands position their products correctly in the market. Each fabric carries its own style connotations.

Denim is iconic. Its primary use is, of course, jeans. But it's also used for jackets, skirts, overalls, and even accessories. Its style is rooted in utility and rebellion, but it has become a timeless fashion staple. Denim can be raw/selvedge, distressed, stretch, or colored. Chambray is most famously used in shirts, often referred to as "denim-lite" shirts. It's also popular for dresses, blouses, and light jackets. Its style is more relaxed, breezy, and slightly preppy compared to denim's ruggedness.

How can brands leverage denim's versatile image?

Denim is incredibly versatile. It can be dressed up or down. A brand can create a high-fashion line using premium denim with unique washes and finishes. Alternatively, they can produce durable, everyday basics. The key is in the finishing processes. As a manufacturer, we offer various washes—from dark rinse to acid wash—to achieve different looks. Denim's ability to incorporate stretch fibers like elastane has also expanded its use into more form-fitting and comfortable garments.

What are the emerging trends for chambray in modern fashion?

Chambray is enjoying a resurgence as consumers seek comfortable and versatile pieces. It's no longer just for classic work shirts. We see trends towards chambray in bohemian-style dresses, rompers, and even home decor items like pillowcases. Its softness and slightly faded, vintage look make it appealing for brands focused on a relaxed, California-cool or cottage-core aesthetic. It's easier to print on than heavier denim, opening possibilities for patterned chambray garments.

How should cost and sourcing considerations influence your choice?

From a business perspective, the decision between denim and chambray affects your bottom line and supply chain.

Generally, basic chambray can be less expensive to produce than medium-weight denim. This is due to the simpler weave and often lighter weight, which uses less raw material. However, high-end selvedge denim or denim with special finishes can command a much higher price. The cost of cotton, dyes, and manufacturing complexity are key factors.

What are the key cost drivers in denim production?

Denim production can be cost-intensive. The indigo dyeing process, especially for rope dyeing which yields higher quality, is complex. The weight of the fabric means higher cotton consumption. Additional processes like sanding, whiskering, or laser finishing add to the cost. For brands, this means denim garments typically have a higher Cost of Goods Sold (COGS) but also a higher potential retail price.

Why is chambray a strategic choice for certain product lines?

Chambray offers a great balance between cost, aesthetics, and comfort. It allows brands to offer a denim-like look at a more accessible price point. This is ideal for fast-fashion cycles or lines with a lower target margin. Its simpler production makes it easier to source and manufacture quickly. For brands looking to test a "denim" category without the higher investment, chambray is an excellent entry point. It's also easier to care for, which can be a selling point for consumers.

Conclusion

Choosing between denim and chambray is not about which fabric is better, but which is better for your specific product. Denim offers unmatched durability and a timeless, rugged appeal for heavy-use items like jeans and jackets. Chambray provides a lighter, softer, and more breathable alternative, perfect for shirts, summer dresses, and comfortable everyday wear. The decision ultimately hinges on your design vision, target market, and budget.

Understanding these differences empowers you to make the right sourcing decision. It ensures the final product meets your quality expectations and resonates with your customers. If you are looking for a reliable manufacturing partner to expertly produce your next denim or chambray collection, we are here to help. Our team can guide you through fabric selection, sampling, and production to bring your vision to life. For a consultation on your apparel order, please contact our Business Director Elaine at elaine@fumaoclothing.com.