Have you ever bought a waterproof jacket, only to find it loses its repellency after a few washes? Or perhaps you're concerned about the environmental and health impacts of the chemicals used to make fabrics water-resistant. If so, you're not alone. The world of water-repellent finishes is undergoing a significant shift, moving away from traditional chemistries toward safer, more sustainable options. At the heart of this change are two key terms: C0 DWR and PFAS-free.

Simply put, C0 DWR and PFAS-free water-repellent fabric refers to high-performance textiles that shed water without using per- and polyfluoroalkyl substances (PFAS), a large group of chemicals known for their persistence in the environment and potential health risks. C0 DWR is a specific, PFAS-free chemistry that provides a durable, high-performing, and eco-friendly water-repellent finish. This innovation is crucial for brands aiming to meet consumer demand for both performance and sustainability.

This article will demystify these terms, explain why this shift is so important for your business, and guide you through the key considerations when sourcing these next-generation fabrics. We will break down the science, the benefits, and the practical aspects of integrating PFAS-free water repellency into your product lines, ensuring you can make informed decisions for your brand's future.

What are PFAS and why are they being banned?

For decades, PFAS were the gold standard for durable water repellency (DWR). Their effectiveness, however, comes with a significant downside. Often called "forever chemicals," PFAS do not break down easily in the environment or in our bodies. This persistence has led to widespread contamination and growing health concerns, prompting strict regulations worldwide. Understanding this legacy is the first step toward embracing safer alternatives.

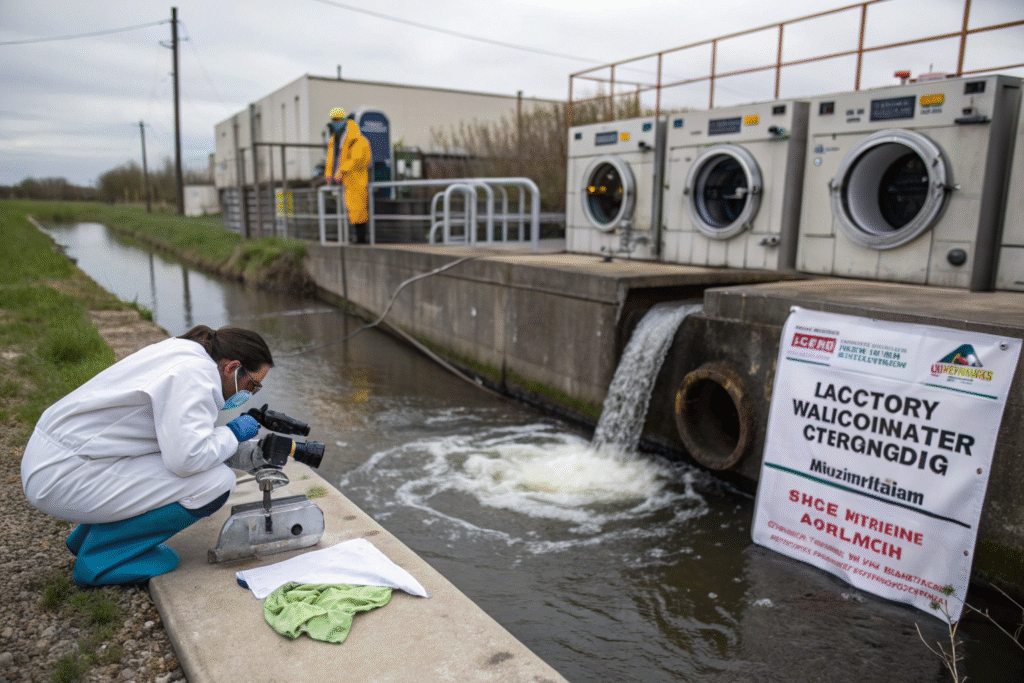

The core issue with PFAS is their environmental persistence. When garments treated with PFAS-based DWR are washed, the chemicals can enter waterways. They bioaccumulate, meaning they build up in wildlife and humans. Studies have linked certain PFAS to a range of health issues. This has led to aggressive regulatory action, especially in the European Union and key US states like California. For apparel brands, this means that continuing to use PFAS is not only an environmental concern but also a significant compliance risk that could disrupt your supply chain.

What does PFAS-free actually mean for my product's performance?

Many brands worry that moving away from PFAS will mean sacrificing the high performance their customers expect. The term "PFAS-free" can seem daunting, implying a loss of functionality. However, advancements in chemistry have closed this gap significantly. Modern PFAS-free DWR treatments, especially high-quality C0 formulations, offer performance that meets or even exceeds that of older technologies.

The key difference lies in the chemistry. While traditional PFAS-based DWR creates a film that water slides off of, many PFAS-free alternatives, including C0 DWR, work by creating a dense, molecular barrier on the fabric's fibers. This barrier has a very low surface energy, causing water to bead up. The best PFAS-free DWRs now achieve high scores in spray tests and maintain their repellency through multiple washes. For example, our in-house testing of C0 DWR finishes shows they can withstand over 20 home laundries while still maintaining a rating of 80 or higher, matching the durability of many legacy PFAS treatments. You can learn more about international testing standards from organizations like Hohenstein and SGS.

How can I verify a fabric is truly PFAS-free?

Trust but verify. As a buyer, you need certainty about your material claims. "Greenwashing" is a real concern, and vague marketing terms are not enough. Ensuring your supplier provides verifiable proof is essential for your brand's integrity and for avoiding potential legal issues related to false advertising.

The only way to confirm a fabric is PFAS-free is through third-party laboratory testing. Reputable suppliers will have test reports from accredited labs like SGS, ITS, or Bureau Veritas. These reports use precise methods to detect the presence of specific PFAS compounds. When evaluating a supplier, always ask for these test certificates. Look for testing against a broad spectrum of PFAS, including PFOA, PFOS, and long-chain variants. At our CNAS-accredited lab, we conduct rigorous PFAS testing for every batch of our PFAS-free fabrics, providing a transparent chain of custody for our clients. This due diligence protects your brand and builds consumer trust.

What is C0 DWR and how does it work?

C0 DWR represents the cutting edge of sustainable water-repellent technology. The "C0" designation specifically means it is a non-fluorinated, or zero-fluorocarbon, finish. It is the leading solution for brands that refuse to compromise on either ecological responsibility or performance. Unlike some early PFAS-free alternatives that were less durable, C0 chemistry has been engineered for longevity and robustness.

C0 DWR works by creating a protective, nano-scale layer on the surface of the textile fibers. This layer is typically based on silicone or dendrimer technology. It changes the fabric's surface tension, making it extremely difficult for water to spread and wet out the material. Instead, water forms tight beads and rolls away. This mechanism is highly effective against rain and stains. Because it contains no fluorocarbons, it is inherently safer for the environment. The development of C0 DWR is a result of significant investment in textile R&D, driven by the industry's need for compliant, high-performance finishes.

Is C0 DWR as durable as traditional DWR?

Durability is the most common question we receive from clients. The answer is that high-quality C0 DWR can be just as durable, if not more so, than older PFAS-based finishes, particularly when applied correctly to a suitable fabric construction. The performance is no longer in question; the focus has shifted to proper application and fabric pairing.

Durability depends on several factors: the quality of the C0 chemistry, the application process, and the base fabric. For instance, a tightly woven nylon will hold a DWR finish better than a loose knit. Our approach involves pre-treating the fabric to ensure optimal adhesion of the C0 finish. We then conduct accelerated abrasion and wash tests to predict real-world performance. The results consistently show that our C0 DWR finishes meet the stringent requirements of outdoor and sportswear brands. The Outdoor Industry Association provides excellent resources on the durability testing of alternative DWR chemistries, confirming their viability for demanding applications.

What are the main benefits of switching to C0 DWR?

The benefits extend far beyond simple regulatory compliance. Switching to C0 DWR is a proactive step that future-proofs your brand, enhances your sustainability profile, and meets the evolving expectations of conscious consumers. It's a decision that aligns performance with principle.

The primary benefits are:

- Regulatory Safety: It eliminates the risk of violating current and future bans on PFAS.

- Environmental Credentials: It allows you to make legitimate "PFC-free" or "PFAS-free" claims, a powerful marketing tool.

- Consumer Health: It ensures your products are safer for end-users.

- Supply Chain Stability: By adopting the new standard early, you avoid last-minute scrambles to reformulate products.

Furthermore, the production process for C0 DWR is often more energy-efficient. For brands looking to achieve certifications like bluesign® or OEKO-TEX® STANDARD 100, using C0 DWR is a significant advantage. We've helped numerous clients reformulate their best-selling styles with C0 DWR, resulting in products that are not only compliant but also resonate strongly with the market. You can explore the criteria for the OEKO-TEX® STANDARD 100 certification to see how chemical restrictions are defined.

How is PFAS-free DWR applied to fabric?

The application process is critical to the performance of any DWR finish, and PFAS-free treatments are no exception. A superior chemistry can underperform if applied incorrectly. The method must ensure even distribution and strong bonding to the fabric fibers to achieve lasting repellency. The most common industrial methods are padding and coating.

In the padding process, the fabric is passed through a bath containing the DWR formulation and then through rollers (pads) that squeeze out the excess liquid, ensuring a precise and even application. This is followed by a drying and curing stage, which bonds the finish to the fabric. For more heavy-duty applications, a coating process might be used, where the DWR is applied as a thicker layer on the fabric surface. At our partner coating factory, we use state-of-the-art computerized systems to control the temperature, pressure, and speed of this process, guaranteeing consistent results batch after batch. This precision engineering is what transforms the chemical solution into a durable fabric feature.

What is the difference between C6, C8, and C0 DWR?

To understand C0, it's helpful to know what came before. The "C" in these codes refers to the length of the fluorocarbon chain in the chemical. C8 DWR, with an 8-carbon chain, was the original high-performance standard but is the most environmentally persistent. C6 DWR was developed as a "shorter-chain" alternative believed to be less bioaccumulative, but it is still a PFAS and is now facing similar restrictions.

C0 DWR is fundamentally different because it contains zero fluorocarbon chains. It is a completely different chemistry. The following table summarizes the key differences:

| Feature | C8 DWR | C6 DWR | C0 DWR |

|---|---|---|---|

| Chemical Basis | Long-chain PFAS | Short-chain PFAS | Non-fluorinated (e.g., silicone) |

| Durability | Excellent | Very Good | Very Good to Excellent |

| Environmental Impact | Very High (Persistent) | High (Restricted) | Minimal |

| Regulatory Status | Banned in many regions | Being phased out | Compliant & Future-proof |

As the table shows, C0 is the only option that offers high performance without the associated environmental and regulatory baggage. The transition from C8 to C6 was a half-step; the move to C0 is the complete solution. The ZDHC Foundation provides detailed guidelines on restricted substances, clearly outlining the path away from all PFAS.

Can PFAS-free DWR be applied to any type of fabric?

While PFAS-free DWR is versatile, its effectiveness can vary depending on the base fabric. The construction, fiber content, and intended use of the fabric all play a role in determining the best type of DWR and application method. A one-size-fits-all approach does not yield optimal results.

Natural fibers like cotton and wool can be treated with PFAS-free DWR, but the finish may not be as durable as on synthetic fibers because the natural fibers absorb more moisture. For these, a different type of finish might be recommended. Synthetic fabrics like polyester and nylon are ideal candidates for C0 DWR, as the finish bonds exceptionally well to their smooth surfaces. Our technical team works with clients to select the right base fabric and DWR combination for the specific end-use, whether it's a lightweight jacket for hiking or heavy-duty workwear. This consultative approach ensures that the final product performs as expected in the field.

What should I look for in a PFAS-free fabric supplier?

Choosing the right supplier is the most critical step in your transition to PFAS-free water-repellent fabrics. The supplier must have deep technical expertise, robust quality control systems, and a genuine commitment to sustainability. Price should not be the primary driver; reliability and proof of compliance are paramount.

You need a partner, not just a vendor. Look for a supplier with verifiable certifications and transparent testing processes. They should openly discuss their chemical suppliers and application methods. Ask about their experience with PFAS-free production runs and request references from other brands they have supplied. A strong supplier will have a dedicated R&D team that stays ahead of regulatory trends and continuously improves their formulations. They should also offer comprehensive support, from selecting the right fabric to providing all necessary documentation for your own marketing and compliance needs.

What certifications prove a fabric is PFAS-free?

Certifications and test reports are your tangible proof. While a supplier's word is important, independent verification is essential. Several internationally recognized certifications and standards can provide the assurance you need to make a confident purchase and market your products accurately.

The most important documents to request are:

- OEKO-TEX® STANDARD 100: This certification tests for harmful substances, including a specific limit for PFAS. A Class I certification (for products for infants) is the most stringent.

- bluesign® APPROVED: The bluesign® system goes beyond the product to audit the entire manufacturing process, ensuring that the chemicals used are safe and sustainable. PFAS are restricted substances under the bluesign® criteria.

- Third-Party Test Reports: Specific lab reports from SGS, ITS, or similar bodies that explicitly state "PFAS Not Detected" for a comprehensive list of compounds.

Always ask for copies of these current certificates. At Fumao, we maintain up-to-date OEKO-TEX® and SGS test reports for all our PFAS-free fabrics, providing our clients with peace of mind and a simplified sourcing process. You can verify a supplier's OEKO-TEX® certification using the official label check database.

How do I manage the cost and sourcing transition?

Transitioning your product line to PFAS-free fabrics may involve some initial cost adjustments, but these are manageable with a strategic approach. The goal is to ensure a smooth supply chain transition without unexpected disruptions or cost overruns.

Open communication with your supplier is key. Discuss your volume requirements and timeline. While high-performance C0 DWR chemistries can be slightly more expensive than outdated PFAS options, economies of scale and efficient application can mitigate the cost difference. Furthermore, the long-term savings from avoiding regulatory fines, recalls, or brand reputation damage are significant. We work closely with our clients to plan a phased transition, often starting with a best-selling style. We provide small-batch customization for sampling and testing, ensuring the new fabric meets all specifications before committing to bulk production. This collaborative approach minimizes risk and ensures a successful shift to a more sustainable and compliant supply chain.

Conclusion

The move to C0 DWR and PFAS-free water-repellent fabrics is no longer a niche trend but a fundamental requirement for any forward-thinking apparel brand. This shift addresses critical environmental and health concerns while delivering the high-performance durability that consumers demand. Understanding the difference between PFAS-free claims, the science behind C0 chemistry, and the importance of verified certifications empowers you to make sourcing decisions that protect both your products and your brand's future.

The journey toward sustainable performance begins with choosing the right manufacturing partner. A supplier with integrated capabilities—from weaving and dyeing to coating and rigorous QC—ensures consistency, compliance, and cost-effectiveness at every stage.

Ready to future-proof your outdoor, sportswear, or fashion line with high-quality, certified PFAS-free fabrics? Contact our Business Director, Elaine, today at elaine@fumaoclothing.com to discuss your specific needs and request samples. Let's collaborate to create high-performance apparel that is both successful in the market and responsible to the planet.