In the competitive world of textile sourcing, you're constantly balancing cost, quality, and increasingly, environmental responsibility. If you're sourcing fabrics like polyester, you've likely heard the term "dope-dyed" or "solution-dyed" and wondered if it's just another industry buzzword or a genuine game-changer. For bulk buyers like yourself, understanding this technology is key to making smarter, more sustainable, and ultimately more profitable decisions for your brand.

Dope-dyed polyester is a type of polyester fabric where color pigments are added to the polymer solution before the fiber is even extruded. This fundamental difference in the dyeing process makes it superior to conventional piece-dyed polyester in several key areas, particularly in water conservation, colorfastness, and overall production efficiency. As a fabric supplier with over two decades in the industry, we've seen a significant shift towards this method, especially among brands targeting the European and North American markets who are keen on reducing their environmental footprint without compromising on quality.

This article will break down everything you need to know about dope-dyed polyester. We will explore its manufacturing process, compare it directly with traditional methods, highlight its significant sustainability benefits, and explain why it represents a smart, long-term investment for your business.

How is dope-dyed polyester manufactured differently?

The name "dope-dyed" comes from the term "dope," which refers to the thick, syrupy polymer solution before it becomes a fiber. The key difference lies in the timing of coloration, which fundamentally changes the material's properties and environmental impact.

In dope-dyeing, the color is an integral part of the fiber itself, not just a surface coating. This integration happens at the very beginning of the production cycle. Masterbatch chips containing concentrated color pigments are mixed with the raw, uncolored polymer chips. This mixture is then melted into a liquid "dope." The colored dope is forced through a spinneret to create continuous filaments. As these filaments cool and solidify, the color is locked permanently within the fiber's structure. This contrasts sharply with conventional dyeing, where already-formed white polyester yarn or fabric is submerged in large baths of hot water and dye chemicals.

What are the key steps in the dope-dyeing process?

The process is highly integrated and efficient. It begins with the selection of high-quality raw materials, including the base polymer and the color masterbatch. The purity of these components is critical for achieving consistent and brilliant colors. The first major step is precise dosing and mixing. The white polymer chips and the colored masterbatch chips are fed into the mixing system in exact proportions. This ensures the final color shade is accurate and uniform across the entire production batch.

Next, the mixture undergoes melting and extrusion. The blended chips are heated until they become a viscous, liquid solution. This is the "dope" stage, where the color is completely and uniformly dispersed throughout the liquid polymer. The colored dope is then extruded through the spinneret to form filaments. Finally, the filaments are drawn, or stretched, which aligns the polymer chains and increases the fiber's strength and durability. The color molecules are physically trapped within this aligned structure, resulting in exceptional color fastness.

How does this method differ from conventional dyeing?

The differences are profound and impact everything from resource consumption to final product quality. Conventional dyeing, also known as piece-dyeing, is a water-intensive process applied to finished grey fabric. It requires massive amounts of hot water, dyes, auxiliaries, and energy. After dyeing, the fabric must be rinsed repeatedly to remove unfixed dyes, generating enormous volumes of contaminated wastewater that requires costly treatment.

Dope-dyeing eliminates the majority of these post-production steps. Since the color is added at the fiber formation stage, the traditional dyeing and rinsing baths are completely bypassed. This leads to a drastic reduction in water usage—often by 60% to 80% compared to standard dyeing. It also slashes energy consumption because there's no need to heat large quantities of water. Furthermore, because the color is inside the fiber, issues like color bleeding, crocking (rubbing off), and fading from washing or exposure to sunlight are significantly reduced.

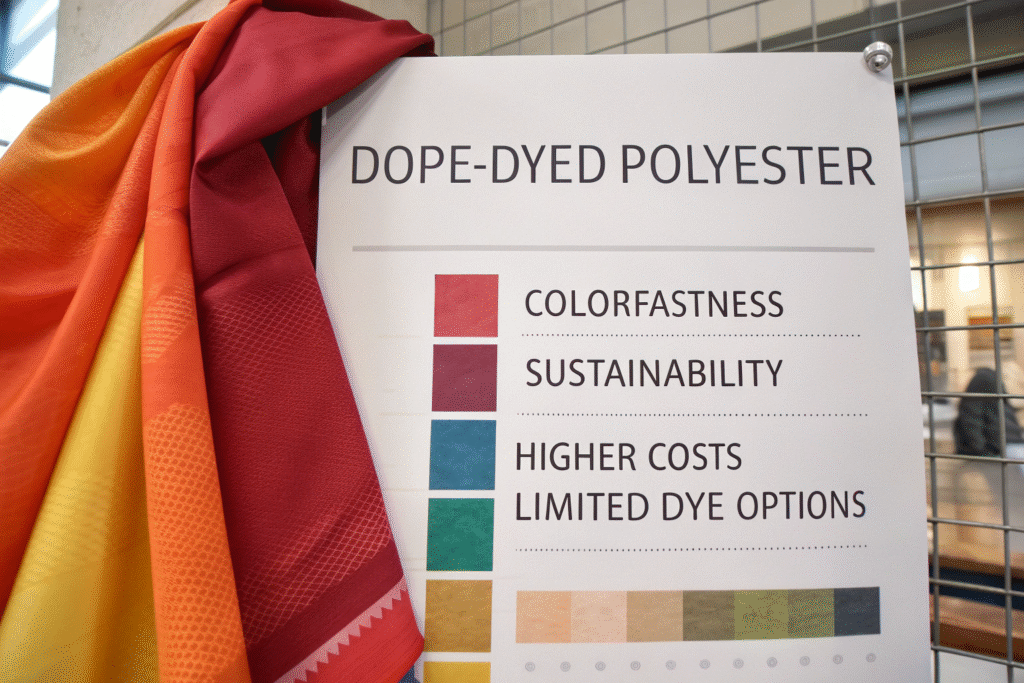

What are the main advantages of using dope-dyed polyester?

The benefits of dope-dyed polyester extend far beyond its eco-friendly production. It offers tangible performance and economic advantages that directly address the pain points of brands and manufacturers.

The most celebrated advantage is its superior colorfastness. The color becomes a fundamental part of the fiber, making it incredibly resistant to fading from washing, abrasion, and UV exposure. This makes it an ideal choice for uniforms, outdoor furniture, athletic wear, and automotive textiles that demand long-lasting vibrancy. From a production standpoint, the process offers greater color consistency from batch to batch, reducing the risk of shade variations in large orders.

Why is the colorfastness of dope-dyed polyester superior?

The reason for its exceptional colorfastness is molecular. In conventional dyeing, dye molecules attach to the surface of the polyester fibers. These surface-level bonds are vulnerable to breaking down under stress, such as friction (crocking), chemical exposure (detergents, chlorine), and ultraviolet radiation. With dope-dyeing, the pigment particles are encapsulated within the solid polymer matrix of the fiber itself. They are physically protected from external factors. This intrinsic coloration means the color cannot be easily washed out or worn away. Tests for light fastness and wash fastness consistently show that dope-dyed fabrics receive the highest ratings, ensuring your products look new for longer, which enhances customer satisfaction and brand reputation.

How does dope-dyeing contribute to sustainability?

The environmental credentials of dope-dyed polyester are a major driver for its adoption. The process aligns perfectly with the principles of sustainable manufacturing and helps brands meet their ESG (Environmental, Social, and Governance) goals. The most significant contribution is in water conservation. The World Bank estimates that nearly 20% of industrial water pollution comes from textile dyeing and treatment; dope-dyeing offers a concrete solution to this problem.

Additionally, the reduction in energy, chemicals, and wastewater leads to a lower carbon footprint. The process generates minimal waste compared to conventional dyeing. Many dope-dyed polyesters are also made from recycled PET (rPET), combining the benefits of recycled content with an eco-conscious dyeing method. This creates a powerful story for brands looking to appeal to environmentally aware consumers. Certifications like the Global Recycled Standard (GRS) can further validate these claims.

What are the limitations and how can they be managed?

While dope-dyed polyester offers numerous benefits, it is not without its challenges. Acknowledging these limitations is crucial for making an informed sourcing decision.

The primary limitation is related to color flexibility. The dope-dyeing process is best suited for large-volume orders of a single color. Because the color is added at the polymer stage, changing colors requires a complete cleaning of the entire production line, which is time-consuming and costly. This makes it less economical for small-batch production or for sampling a wide range of colors quickly.

Is the color range for dope-dyed polyester limited?

It's a common misconception that the color range is severely limited. While it's true that the process is most efficient for standard and popular colors, technological advancements have significantly expanded the available palette. At our company, we maintain a extensive library of masterbatches, allowing us to offer a wide spectrum of colors. However, achieving very specific, custom Pantone-matched shades can be more challenging and may require a higher minimum order quantity (MOQ) to be feasible. For startups or brands that require extreme color agility, piece-dyeing might still be necessary for certain lines. The key is to work with a supplier who can advise on the most cost-effective and sustainable approach for your specific needs.

How do lead times and minimums compare to conventional fabrics?

The production lead time for dope-dyed fabric can be longer for the initial order, especially if a new color needs to be developed. However, this is offset by the speed of subsequent production runs. Once the color is set, the manufacturing process is highly streamlined. There are no delays for dyeing and finishing the grey fabric, as the colored yarn is ready to be woven or knitted directly into the final product.

Regarding Minimum Order Quantities (MOQs), they are typically higher for dope-dyed fabrics than for conventionally dyed ones. This is due to the setup costs involved. However, for established brands with predictable color needs, the economies of scale, combined with the savings on water, energy, and wastewater treatment, often result in a lower total cost per meter for large orders. We recommend planning your color strategy ahead of time and consolidating orders to make the most of this technology.

Conclusion

Dope-dyed polyester is far more than a passing trend; it is a smarter, more sustainable approach to textile coloration that directly addresses the environmental and performance challenges of our time. Its core benefits—exceptional colorfastness, significant resource savings, and a reduced ecological footprint—make it an compelling choice for forward-thinking brands. While it requires strategic planning around color selection and order volume, the long-term advantages for your product quality and brand story are substantial.

If you are looking to develop high-quality, durable, and eco-friendlier apparel or textile products, dope-dyed fabrics offer a proven path forward. We invite you to explore our range of dope-dyed polyester options and see how we can integrate this innovative material into your next collection. For more information and to discuss your specific requirements, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's work together to create value that lasts.