Buyers and safety managers working in protective clothing industries often struggle with sourcing fabrics that truly meet international fire and heat resistance standards. Many suppliers advertise “flame-resistant fabrics,” but without reliable test data, customers risk purchasing textiles that fail in critical conditions. This problem delays production, raises liability, and creates costly mistakes.

ISO 17492:2019 provides a globally recognized test method to evaluate fabrics under simultaneous exposure to flame (convective heat) and radiant heat. Fabrics that pass this test demonstrate measurable thermal protection performance, making them ideal for firefighter gear, industrial PPE, and military uniforms. Knowing how to source these materials ensures safety, compliance, and supply chain reliability.

This article explains what ISO 17492 is, what makes a fabric compliant, where to source certified textiles, and how to evaluate suppliers.

What Is ISO 17492 Convective Heat Resistance?

ISO 17492 is a specialized test standard developed by the International Organization for Standardization. It is widely used in protective clothing certification.

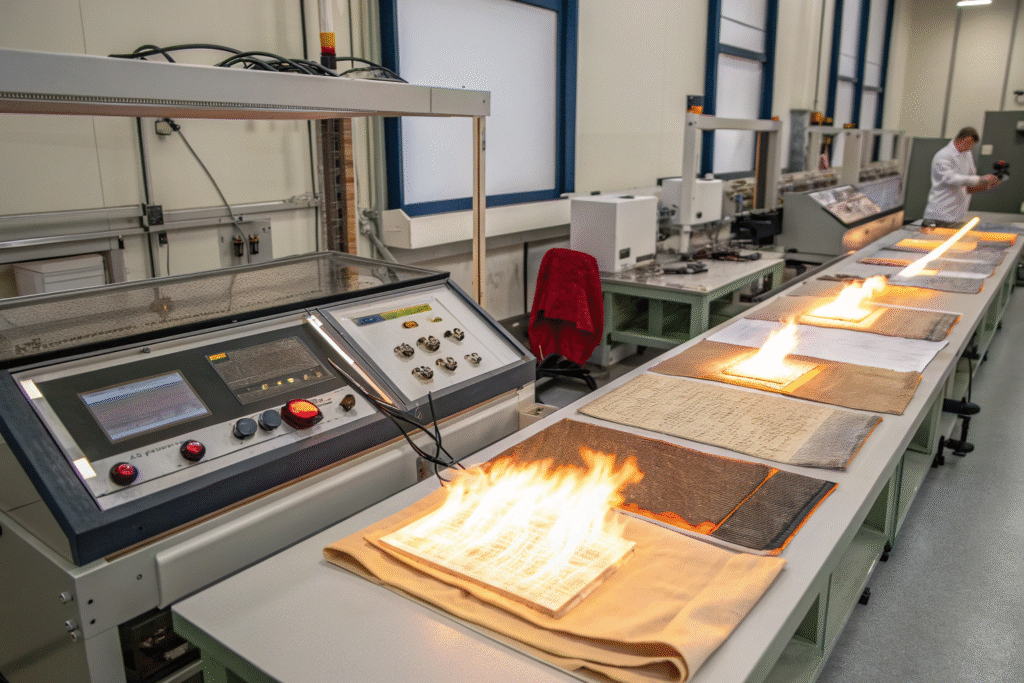

The method exposes fabric samples to a combination of flame and radiant heat at a total heat flux of 84 kW/m². It measures how much heat transfers through the material, producing data like the Thermal Protection Index (TPI) and Heat Transfer Index (HTI). These values indicate how long the fabric can protect the wearer before the onset of second-degree burns.

Why Is This Test Unique?

Unlike other standards that measure radiant or flame exposure alone, ISO 17492 evaluates both simultaneously. This mirrors real-world conditions where workers face mixed heat environments, such as fires.

Which Fabrics Are Eligible?

The test applies only to flame-resistant fabrics. Eligible materials include:

- Aramid fibers (e.g., Nomex®, Kevlar®)

- Flame-retardant treated cotton blends

- Modacrylic or FR viscose blends

- Multi-layer protective assemblies

Details can be found in ISO’s publication of the standard.

Where Can You Source ISO 17492 Compliant Fabrics?

Finding suppliers who can provide ISO 17492 tested fabrics requires focusing on specialized manufacturers and certified testing.

Reliable sources include aramid fiber producers, global PPE fabric manufacturers, and accredited Chinese textile mills with FR treatment capability. These suppliers often also comply with related standards like ISO 11612 and NFPA 1971.

Which Global Suppliers Are Known?

- DuPont™ Nomex® – global leader in aramid protective fabrics.

- Teijin Aramid – manufacturer of Twaron® aramid fibers.

- TenCate Protective Fabrics – international PPE textile provider.

What About Asian Suppliers?

China, India, and Southeast Asia have strong FR textile producers. For example, Keqiao-based manufacturers can develop aramid blends with PU or FR coatings and submit them for ISO 17492 testing at CNAS-accredited labs. Factories in Suzhou and Xinxiang also specialize in FR cotton and modacrylic blends.

Platforms like Global Sources and Alibaba list potential vendors, but direct verification is essential.

How to Evaluate Supplier Claims?

Not every supplier claiming “ISO 17492 tested” provides genuine results. Proper evaluation avoids costly risks.

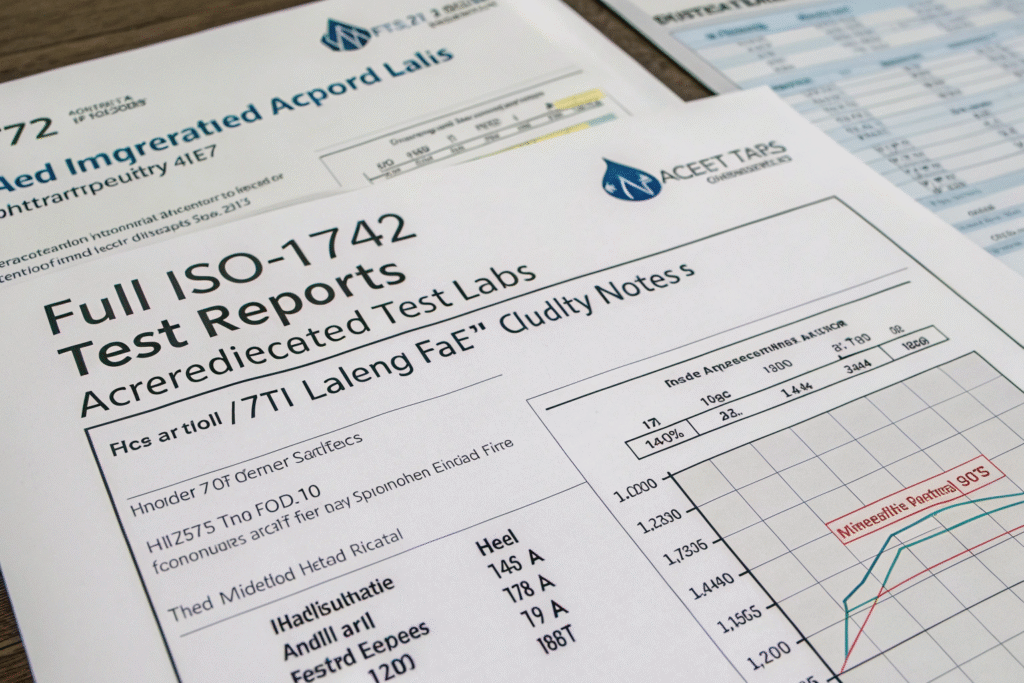

Always ask for full ISO 17492 test reports from accredited labs. Reports must include HTI and TPI values, with heat rise curves. Avoid suppliers who provide only generic “pass/fail” notes.

What Tests Should You Ask For?

- Heat Transfer Index (HTI 24/12)

- Thermal Protection Index (TPI)

- Wash durability of FR finishes

- Tensile, tear, and abrasion resistance

Reputable testing agencies include SGS and Intertek.

Why Reports Matter?

End-users in firefighting or industrial safety demand certified results. Without reports, products risk rejection, warranty disputes, or safety failures.

How Can Manufacturers Like Fumao Fabric Add Value?

Sourcing ISO 17492 fabrics is not just about buying from big names. Manufacturers with strong R&D and certified labs can develop competitive options.

At Fumao Fabric, we control weaving, FR finishing, and coating. Our CNAS-accredited lab can run pre-tests before submitting to third-party labs. This reduces development cycles and ensures fabrics meet performance requirements quickly.

What Advantages Do We Provide?

- Faster sample turnaround (48 hours)

- Customized FR blends (aramid/cotton, modacrylic/polyester)

- In-house testing before certification

- Lower cost and tariff advantages for global buyers

How Do We Support Buyers?

We provide:

- Full technical packs with fiber content and finishing methods

- ISO 17492, ISO 11612, and NFPA-related reports

- Batch consistency with QR code tracking

- Integrated logistics and customs clearance

Buyers comparing suppliers on Alibaba or Global Sources will find many options, but working with a direct manufacturer like us ensures accountability and quality.

Conclusion

ISO 17492 tested fabrics are essential for protective clothing where workers face combined flame and radiant heat. Sourcing them requires understanding the standard, checking for certified reports, and selecting suppliers with proven expertise.

Global leaders like DuPont and TenCate provide aramid-based solutions, while Asian manufacturers like Fumao Fabric deliver cost-effective, customizable options tested at accredited labs.

If you are developing PPE or protective apparel, sourcing ISO 17492 compliant fabrics ensures compliance, safety, and performance. To start your project, contact our Business Director Elaine at elaine@fumaoclothing.com for samples, reports, and tailored sourcing solutions.