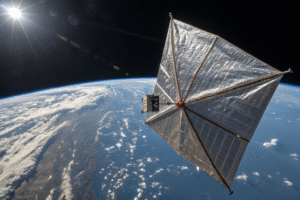

When most people picture spacecraft propulsion, they imagine rockets erupting with fire and smoke. Yet far from Earth, propellant becomes a burden—it is costly, heavy, and limited. In this context, solar sails emerge as an elegant solution. Instead of consuming fuel, they harness sunlight with ultra-thin reflective membranes, allowing satellites to glide forward powered only by photons. Selecting the right film is crucial: if it overheats, tears, or reflects light poorly, the mission could end in failure.

The most effective materials for solar sails are films that combine light weight, high reflectivity, and thermal endurance. Examples include aluminized polyimide (Kapton), polyethylene naphthalate (PEN), and polyester (Mylar). These composites balance low density with strong mechanical strength, enabling spacecraft to capture solar radiation efficiently. While novel materials such as graphene hold promise for the future, current missions still rely primarily on proven polymer–metal laminates.

A solar sail is more than a technical device—it represents reliability and trust. Agencies and researchers need confidence that deployment will proceed flawlessly, that the sail will maintain stability for years, and that it can withstand the extremes of space. In the following sections, I will review the fabrics that meet these requirements, their properties, and their performance in real missions.

Why Is Fabric Choice Critical for Solar Sails?

Designing a solar sail forces engineers into a delicate compromise. The membrane must be robust enough to endure deployment and resist micrometeoroid impacts, while also remaining light enough to accelerate under the faint push of sunlight. For this reason, fabric selection is the foundation of every mission.

Material choice dictates the efficiency of photon-driven thrust, the probability of successful deployment, and the durability of the sail in the harsh space environment. Polymers such as Kapton, Mylar, and PEN have been optimized to deliver both strength and reflectivity.

Thermal performance is another decisive factor. Under direct sunlight, surfaces can reach several hundred degrees Celsius, yet when passing into shadow, temperatures may drop near absolute zero. A weak film could crack, warp, or lose reflectivity within weeks.

How Does Reflectivity Influence Solar Sail Efficiency?

The pressure from sunlight works only if photons are reflected, not absorbed. A sail with low reflectivity converts much of the incoming energy into heat rather than motion, which reduces acceleration and increases thermal stress. This is why aluminum-coated films are standard. According to NASA, such films strike the best balance between reflectivity and mass, generating measurable thrust even from faint solar radiation.

Over time, cosmic radiation gradually damages surfaces, lowering reflectivity. Polyimide-based films like Kapton resist ultraviolet degradation more effectively than cheaper plastics. To maintain performance, engineers often add secondary coatings such as chromium, which regulate heat emission and prevent warping. Without these layers, sails might deform or fail long before mission completion.

What Is the Role of Thermal Endurance?

Spacecraft experience dramatic thermal shifts as they move between sunlight and darkness. Polyimide films such as Kapton withstand extreme conditions, operating from −269°C up to +400°C. By comparison, Mylar degrades above 150°C, which limits its use in hotter environments. This explains why early projects like LightSail succeeded in low-Earth orbit but would struggle farther from Earth.

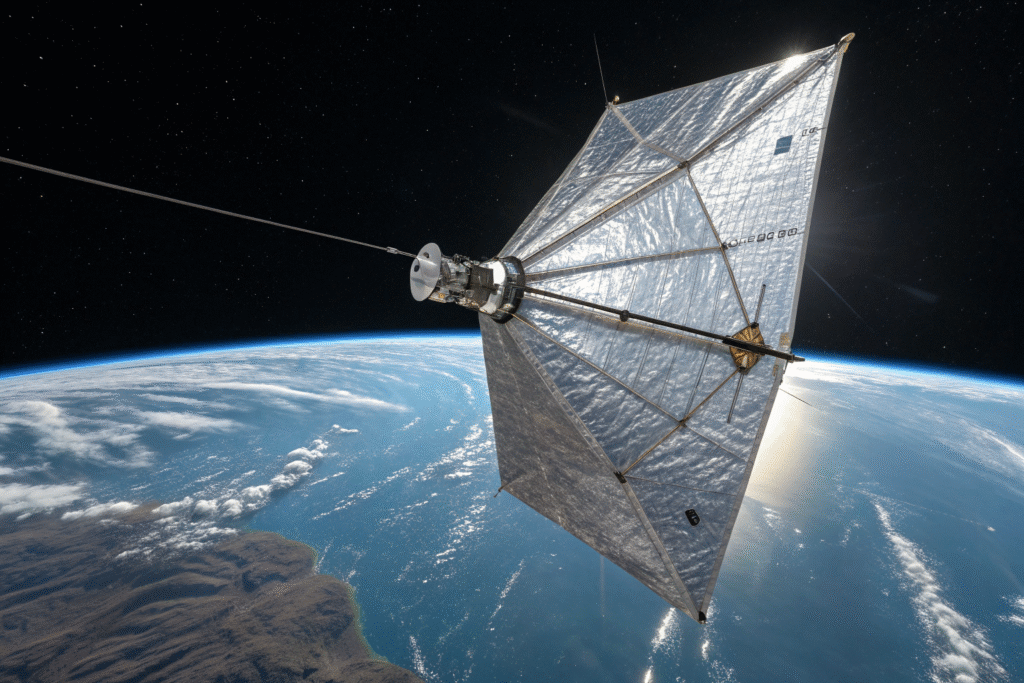

A more recent example is NASA’s ACS3 mission, which selected PEN film coated with aluminum and chromium. PEN provides better thermal resilience than Mylar while weighing less than Kapton. As exploration expands toward interplanetary missions, heat resistance is becoming just as important as reflectivity.

Which Fabrics Have Been Validated in Actual Missions?

Theories about solar sails are only valuable if confirmed in orbit. Each experimental mission offers proof of what works and what fails, particularly when sails must survive deployment, space radiation, and long operational lifetimes.

The most reliable fabrics to date are aluminized Kapton, Mylar, and PEN. They have been flown successfully by JAXA, NASA, and the Planetary Society.

These missions highlight trade-offs: Mylar is inexpensive and reflective but thermally fragile; Kapton is strong and heat-resistant yet heavier and costlier; PEN offers a middle ground. Graphene and other advanced films are still under investigation, showing promise but not yet ready for large-scale deployment.

What Material Powered JAXA’s IKAROS?

In 2010, JAXA’s IKAROS spacecraft became the first probe to travel interplanetary space using a solar sail. It employed an aluminized polyimide film just 7.5 microns thick, light enough to accelerate under sunlight yet strong enough to survive space exposure. According to Wikipedia, the material’s areal density was only about 10 g/m².

IKAROS also introduced innovation by embedding liquid-crystal devices into the film. These allowed selective changes in reflectivity, giving the spacecraft steering capability. This achievement proved that ultrathin polymer films can both endure and function effectively far from Earth.

Why Did LightSail Missions Select Mylar?

The Planetary Society’s LightSail projects in 2015 and 2019 adopted aluminized Mylar. Mylar was chosen for its affordability, flexibility, and ease of integration into small CubeSats. As Wired reports, the sail was only 4.5 microns thick.

Although less thermally stable than Kapton, Mylar was sufficient for operations in Earth orbit, where environmental extremes are less severe. LightSail demonstrated that even low-cost films can deploy reliably and validate the solar sailing concept.

What Advances Are Driving Future Solar Sails?

While Kapton and Mylar dominate present-day applications, research is advancing toward lighter, stronger, and smarter fabrics. These next-generation materials may eventually enable interstellar exploration.

Emerging developments include PEN-based composites, enhanced coatings, and experimental films such as graphene. Each aims to overcome existing limits in durability, mass, and reflectivity.

Future sails will need to endure higher solar flux near the Sun or remain functional for decades in deep space. Material science, therefore, continues to be the foundation of solar sail technology.

Why Is PEN Becoming More Popular?

NASA’s ACS3 demonstration highlighted the advantages of aluminized PEN. As noted by Time, PEN offers greater mechanical stability and thermal control than Mylar, while remaining more affordable than Kapton.

Its dual-layer design—aluminum on one side to maximize reflectivity, chromium on the other to regulate emissivity—provides a strong balance of properties. This makes PEN an attractive option for missions that must operate for extended periods without excessive cost.

Could Graphene Transform Solar Sailing?

Graphene has been described as a “wonder material.” It is exceptionally light, strong, and conductive. Researchers have proposed that graphene-based sails, when paired with powerful lasers, might reach relativistic speeds, enabling travel beyond our solar system. According to arXiv, such sails could one day support interstellar missions.

The challenge lies in manufacturing: producing large, defect-free graphene sheets is not yet feasible. For now, graphene remains a vision rather than a practical solution. Still, it represents the ultimate goal—sails that are lighter, tougher, and faster than today’s films.

How Do Engineers Balance Weight, Cost, and Reliability?

Even the most advanced material is useless if it cannot be produced economically or deployed safely. Engineers must always balance mass, durability, and financial constraints when planning a solar sail.

Every mission reflects this trade-off. Kapton offers excellent stability but comes at high cost; Mylar is cheap yet fragile; PEN stands between them; and graphene is still experimental.

This framework guides agencies, universities, and private organizations in choosing the right fabric for specific goals.

How Do Missions Select Between Kapton, Mylar, and PEN?

The choice depends on orbit, mission duration, and available funding. For short tests in low-Earth orbit, Mylar suffices. For deeper, hotter missions, Kapton remains the safest option. For medium-cost, longer-duration projects, PEN offers balance. NASA’s ACS3 is an example of this pragmatic compromise.

A study from AIAA compares these films, noting that Kapton’s resilience justifies its expense, whereas Mylar’s affordability is offset by faster degradation. PEN, again, serves as a balanced alternative.

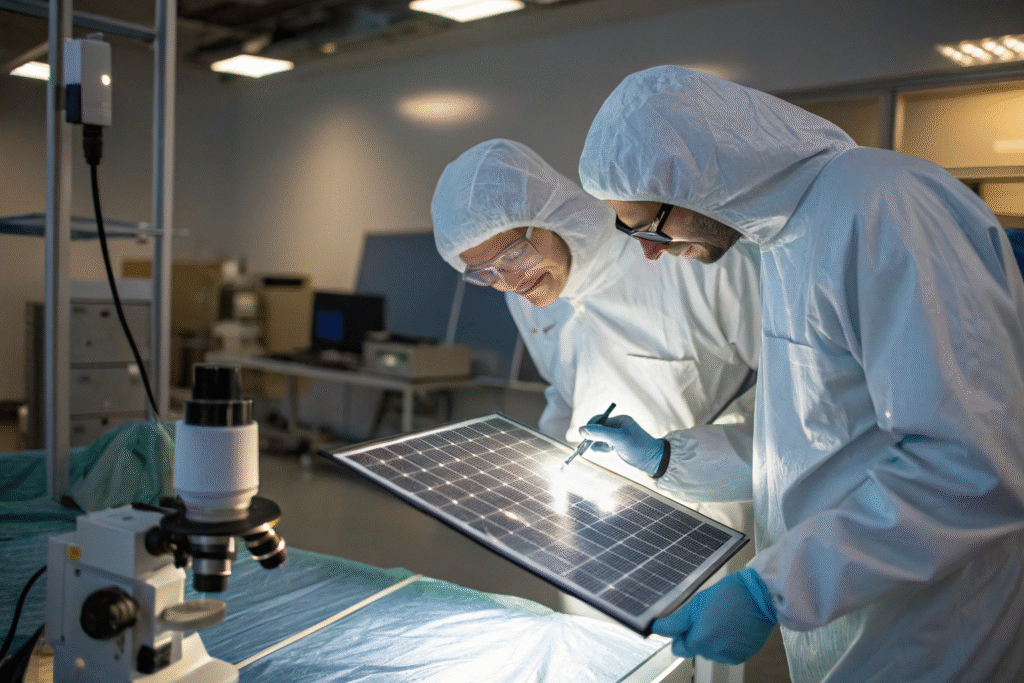

How Is Fabric Reliability Tested?

Before flight, candidate films undergo extensive qualification. Engineers simulate vacuum conditions, bombard them with ultraviolet light, and subject them to rapid thermal cycling. Deployment is also rehearsed repeatedly to ensure folding and unfolding do not create cracks or wrinkles. According to ESA, these tests confirm that films can retain both structural integrity and reflectivity under real conditions.

Only after passing such rigorous checks can a fabric be trusted to operate as part of a spacecraft.

Conclusion

The leading fabrics for solar sails today are aluminized Kapton, Mylar, and PEN. Each presents distinct advantages: Kapton is durable, Mylar is economical, and PEN provides balance. Looking ahead, graphene and other advanced films may expand possibilities for interstellar travel.

Solar sails illustrate how material science can propel spacecraft without fuel, opening new horizons for exploration. Just as textiles shaped progress on Earth, they may one day carry humanity to distant stars.

For organizations seeking a dependable partner in advanced fabric development, we at Shanghai Fumao are ready to collaborate. Please contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss tailored solutions for your mission.