Every cyclist knows that a helmet can save lives, yet many still worry whether the materials inside truly meet the highest safety standards. For buyers and manufacturers, choosing the wrong impact absorption textile could mean costly failures in certification, damaged reputation, and even legal liability. This uncertainty often stops good business deals before they start.

The truth is, EN 1078-certified textiles are not only available, but they are also evolving with new innovations that make helmets lighter, safer, and more comfortable than ever before. From advanced foams to next-generation auxetic structures, the supply market is expanding to meet global demand.

If you want to understand where to source these textiles and what makes them stand out, you need more than a list of names—you need to know the strengths, applications, and supplier strategies behind them. Let’s explore.

Best Materials for EN 1078 Helmet Liners

The search for EN 1078-certified materials always begins with the liner, as it is the first and last defense during an impact. Many new textiles now challenge traditional EPS by offering multi-impact capability and lighter weight.

The best EN 1078 helmet liner textiles include EPS alternatives such as Impaxx foam, Nitrex shock-absorbing foam, SKYDEX proprietary liners, and 3D-printed auxetic TPU structures. Each material addresses a different pain point: single-use safety, repeated impacts, weight, and comfort.

Why Choose Nitrex Foam for Helmets?

Nitrex foams by EVA Glory are engineered for multi-impact performance. Unlike EPS, which crushes permanently, Nitrex rebounds and maintains its absorption even after repeated crashes. It is also certified for EN 1078, EN 1077, and NOCSAE, making it a versatile choice for different sports markets. In addition, its closed-cell structure resists moisture and sweat, improving hygiene for long-term use. Compared to traditional liners, buyers can expect lighter helmets with better ventilation, meeting both safety and comfort needs. You can learn more about helmet foam innovation at ASME.

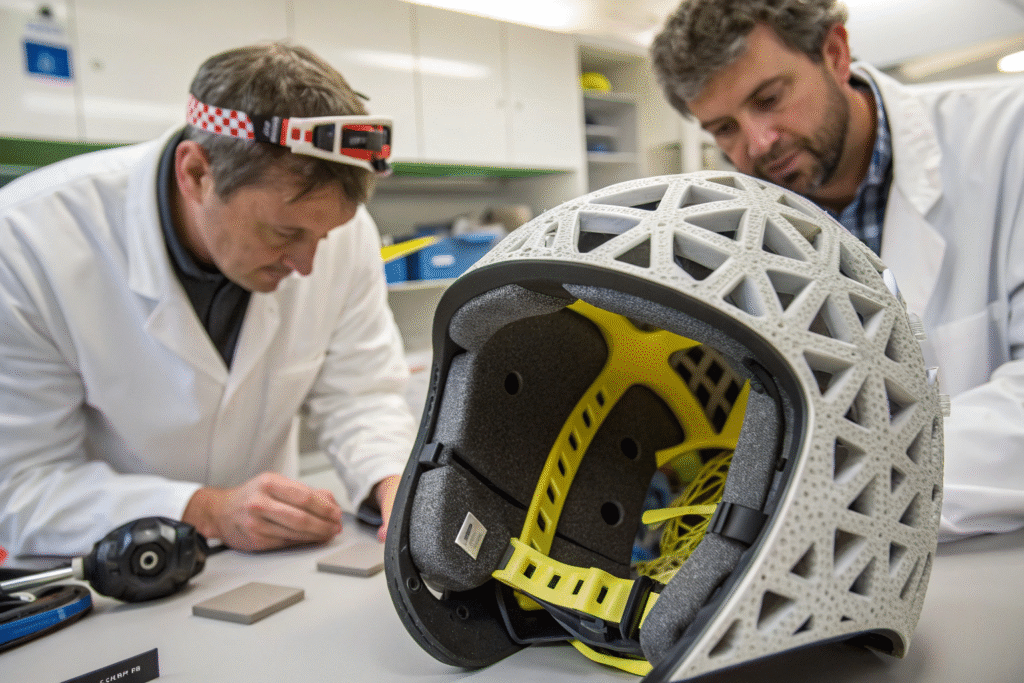

Can 3D-Printed Auxetic Structures Replace EPS?

Auxetic structures, printed in TPU, deform differently during impact, expanding sideways when compressed. This unique behavior allows them to absorb more energy than EPS. Research published on ScienceDirect shows up to 25% lower peak acceleration compared with conventional foams. Customization is also easier: 3D printers can produce personalized helmet liners on demand, ideal for premium brands or racing applications. Manufacturers exploring this direction should collaborate with advanced additive manufacturing labs such as those covered by 3Printr.

Where to Source EN 1078 Certified Helmet Foams?

Global sourcing is not just about finding foam—it is about securing a reliable supply chain. Buyers from the U.S. and Europe need materials that can pass customs smoothly, meet certification audits, and arrive on time.

Suppliers like EVA Glory (Nitrex), SKYDEX, and Polyurethane Laboratories offer ready-to-certify foams that already align with EN 1078 requirements. By working with these companies, buyers reduce the risk of failed testing and delayed product launches.

Which Companies Lead in Multi-Impact Helmet Foams?

SKYDEX has developed impact mitigation systems that outperform EPS in multi-hit scenarios. Their liners retain up to 43% more energy absorption on a third impact, making them ideal for military, rescue, and extreme sports helmets. Another leader is Poly Labs, which manufactures custom polyurethane foams tailored to different densities, shapes, and safety levels. These suppliers focus on both EN 1078 certification and ergonomic comfort, which is crucial for premium helmets sold in Europe and America.

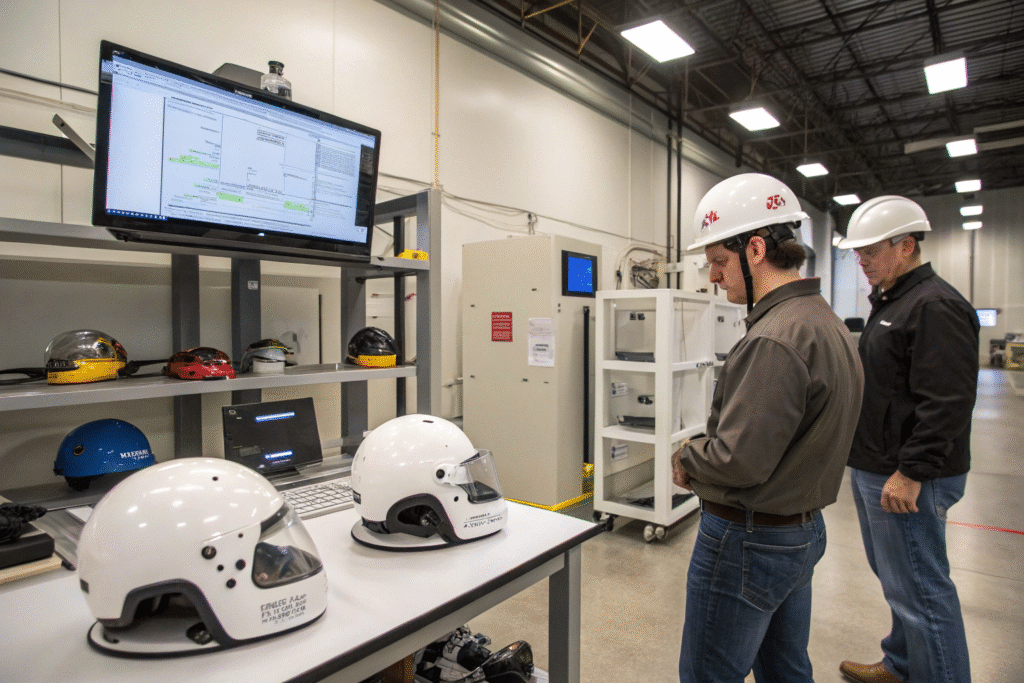

How to Test Foams Before Bulk Orders?

Even when sourcing from established suppliers, sample testing is essential. Most suppliers provide small-batch prototypes for helmet drop rig testing under EN 1078 protocols. Buyers should confirm impact absorption data (<250g peak acceleration) and check multi-impact performance. Resources such as EPS Foam Tech explain the limitations of EPS and the advantages of alternatives. Buyers can also request independent lab reports, often from SGS or TÜV, to verify certification. Detailed records help avoid disputes and ensure compliance during mass production.

The Future of Helmet Impact Textiles

The industry is moving beyond simple EPS. Buyers now look for sustainability, durability, and customization. Helmets of the future will not only protect but also adapt to consumer expectations in comfort and eco-friendly design.

Next-generation helmet textiles include recycled foams, biodegradable blends, and hybrid materials combining auxetic lattices with natural fibers. Research institutions and start-ups are pushing boundaries, while global brands are beginning to invest in sustainable helmet collections.

Are Sustainable Helmet Materials Becoming Standard?

Yes, sustainability is no longer optional. Companies like Tencel are proving how regenerated fibers can enter high-performance markets. While most helmets still rely on petroleum-based foams, R&D projects now explore biodegradable helmet liners made from natural polymers or recycled plastics. Consumers, especially in Europe, demand eco-certified products, and EN 1078 compliance is being combined with EU eco-labels. Helmets featuring both safety and sustainability will gain higher acceptance in premium retail markets.

Will Custom-Fit Helmets Dominate the Market?

The trend toward custom-fit helmets is accelerating. With 3D scanning and additive manufacturing, buyers can design helmets that match head shapes precisely. Studies show that a proper fit significantly reduces rotation and impact force during crashes. Companies featured on ASME highlight how auxetic lattices can adapt to different anatomies. For suppliers, this opens a new premium market where customers pay more for personalized safety. By investing in custom textile technologies, manufacturers will capture demand from professional cyclists and health-conscious consumers.

How to Ensure Certification and Compliance?

Sourcing the right textile is not enough if certification fails. Buyers need to ensure that every shipment can pass audits and customs without delay.

The key is to work with suppliers that provide full EN 1078 compliance documentation, third-party test reports, and transparent quality control processes. This not only protects your brand but also speeds up market entry.

What Documents Are Needed for EN 1078 Helmets?

Buyers should request the following from suppliers:

- EN 1078 test reports from accredited labs like SGS, TÜV, or ITS.

- Material composition data sheets with safety and chemical compliance.

- Batch tracking systems using QR codes for traceability.

Suppliers like ITS Testing Services specialize in providing certification support, making sure helmets meet EU import regulations. Without these documents, customs clearance may face delays, increasing cost and risk.

How to Avoid Delays in Logistics and Customs?

Tariff and logistics challenges can be reduced by sourcing from suppliers with global warehousing and financial stability. Some companies, like SGS, provide pre-shipment inspections to guarantee compliance before goods leave the factory. Others offer Silk Road logistics solutions to speed up shipping into Europe. Buyers should always evaluate whether a supplier has reliable export resilience and can provide insurance-backed contracts.

Conclusion

EN 1078 certified impact absorption textiles are no longer limited to basic EPS foams. Today, buyers can choose from Nitrex, SKYDEX, auxetic TPU, polyurethane blends, and even sustainable materials. Each option offers unique advantages in multi-impact protection, comfort, and certification readiness. To stay competitive, sourcing managers must align safety, cost, and sustainability while working only with suppliers that guarantee compliance.

If you are ready to develop or scale your helmet textile supply, we at Shanghai Fumao can support you with end-to-end solutions—from fabric innovation and foam supply to packaging and customs clearance. To start your custom helmet textile project, contact our Business Director Elaine at elaine@fumaoclothing.com today.