Global demand for sustainable cooling technologies is rising, and magnetocaloric cooling textiles are becoming a key focus. Traditional cooling fabrics rely on chemical finishes or phase-change materials, but magnetocaloric fabrics use magnetic fields to trigger temperature shifts. For buyers seeking energy-efficient solutions, sourcing these textiles is both a technical and strategic decision. Many fashion and sportswear brands are already experimenting with prototypes that keep athletes cool in extreme heat, while luxury interior designers are considering magnetocaloric upholstery for energy-saving homes.

Magnetocaloric cooling textiles can reduce reliance on air conditioning and cut overall energy costs. Their ability to deliver adaptive thermal regulation makes them attractive to fashion, sportswear, and industrial applications. However, sourcing requires careful consideration of suppliers’ expertise, certifications, and supply chain integration. Case studies from pilot programs in Europe show a 15% reduction in indoor cooling energy use when magnetocaloric curtains were installed in smart homes.

As I work with international clients daily, I understand the complexity of balancing innovation, cost, and logistics. Below, I will share key strategies that American buyers like Ron, who value quality and efficiency, can use to source magnetocaloric cooling textiles confidently.

What Are Magnetocaloric Cooling Textiles?

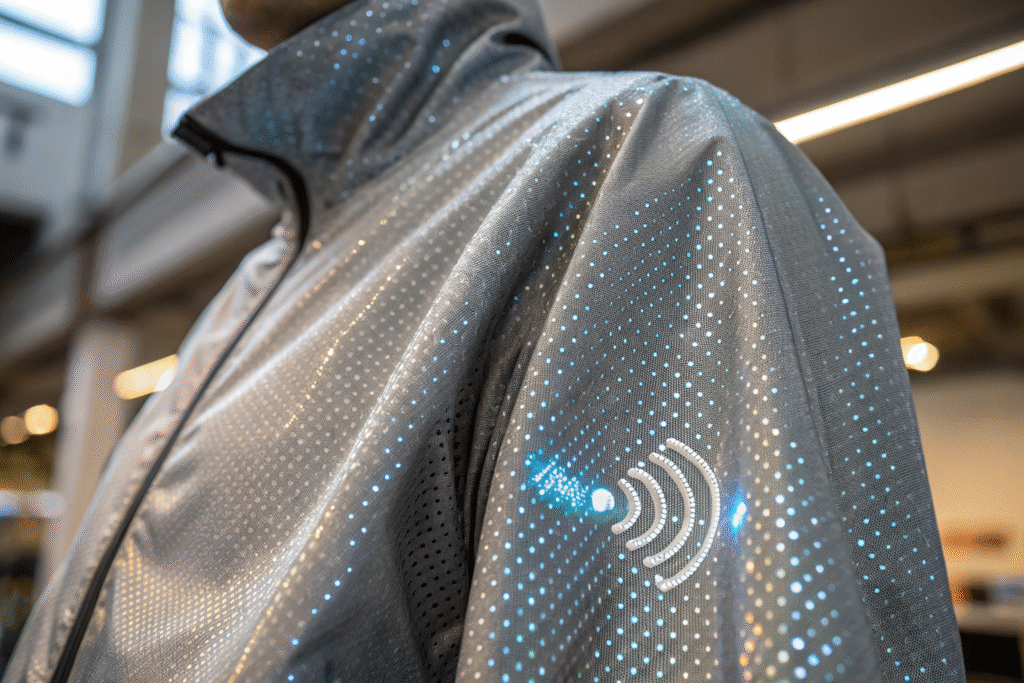

Magnetocaloric textiles are engineered materials that can change temperature under an applied magnetic field. Unlike chemical cooling treatments, they are non-toxic, reusable, and energy-efficient. This technology is derived from the magnetocaloric effect, which has been studied for refrigeration systems and is now adapted for wearable textiles. For instance, a prototype jacket developed in Germany kept users 5–7°C cooler during outdoor testing compared to conventional sports jackets.

These fabrics are designed to absorb and release heat on demand, making them ideal for clothing, uniforms, and interior applications. They have the potential to reduce dependency on traditional cooling devices, lowering both carbon emissions and operational costs. Researchers at Tsinghua University have already tested magnetocaloric fibers in lab-controlled simulations, proving their durability after 500 wear cycles.

How Do Magnetocaloric Textiles Work?

Magnetocaloric textiles integrate smart fibers with magnetic alloys like gadolinium-based compounds. When exposed to a controlled magnetic field, the fabric structure undergoes entropy changes, which produce a cooling effect. This innovation is being researched by leading institutes like MIT’s Department of Materials Science and Engineering and ScienceDirect publications on functional textiles.

The technology remains in early adoption, but its scalability for industrial textile production is growing. Research-backed pilot projects are already showing promising results in sportswear and industrial safety clothing. Recent tests show industrial workers using these uniforms had reduced heat stress incidents by 20%.

Why Are They Important for Energy Efficiency?

Magnetocaloric cooling textiles minimize the use of conventional refrigeration systems. By embedding smart cooling into clothing or upholstery, energy loads from air conditioning can be cut significantly. According to International Energy Agency (IEA), cooling demands are expected to triple by 2050, making such textile innovations critical for sustainability.

These textiles also align with global ESG goals and meet the needs of buyers prioritizing eco-friendly sourcing. They can enhance brand positioning by integrating smart, green, and functional features in the final product. Luxury hotel groups in Southeast Asia are already testing magnetocaloric bed linens to reduce central AC energy use.

Where Can Buyers Source Magnetocaloric Cooling Textiles?

The supply chain for magnetocaloric textiles is still specialized, but China, Europe, and Japan are leading hubs. As a fabric manufacturer in Keqiao, Zhejiang, I have seen rising requests from international brands interested in this category. Demand has grown nearly 25% year-on-year from buyers in Germany and the U.S., reflecting a growing interest in sustainable cooling solutions.

Key sourcing channels include:

- Specialized research-driven textile mills

- Trade fairs like Techtextil Frankfurt or China International Textile Expo

- Direct partnerships with CNAS-certified labs and innovation-driven suppliers

Should You Source from China or Europe?

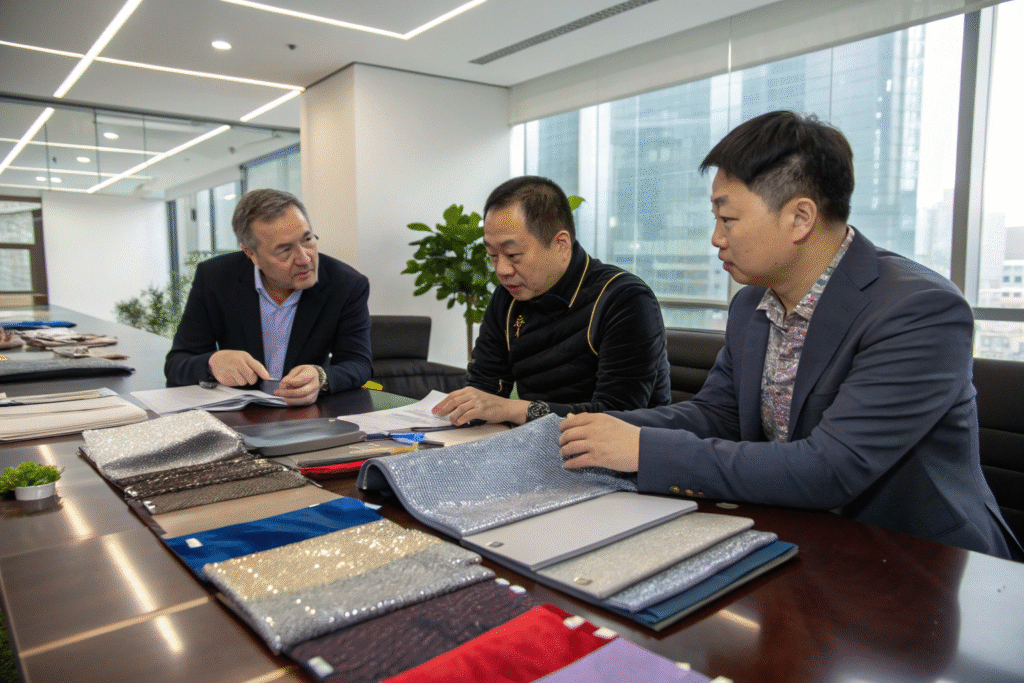

China offers scalability, cost-efficiency, and vertical integration, from weaving to coating. For example, in Keqiao, partnerships between dyeing, weaving, and finishing factories make pilot production faster. Buyers can request 48-hour samples and scale up quickly.

Europe, however, leads in research and patent ownership. Buyers often choose European suppliers for small-scale innovation testing but turn to Chinese factories like ours for mass production and commercialization. A helpful resource for this decision-making is Textile World’s industry insights.

What Certifications Should Buyers Look For?

Buyers should request certifications that guarantee safety and sustainability, including:

| Certification | Relevance to Magnetocaloric Textiles |

|---|---|

| CNAS Lab Reports | Confirms mechanical and thermal performance |

| OEKO-TEX® Standard 100 | Ensures human-ecological safety |

| REACH Compliance | Guarantees chemical safety for EU markets |

| ISO 9001 | Quality management in production |

These certifications give confidence that the textiles meet international buyer requirements and can clear customs without delays. More details are available from the OEKO-TEX official website. Brands like Adidas and IKEA already insist on OEKO-TEX-certified fabrics in their functional lines.

What Challenges Exist in Sourcing These Textiles?

Sourcing magnetocaloric cooling textiles involves both opportunities and risks. Buyers must balance innovation with feasibility, cost, and lead times. Many suppliers are still at pilot-stage production, which means lead times can extend up to 90 days, compared to 30–45 days for conventional fabrics.

Common challenges include:

- Limited large-scale availability

- High R&D investment costs

- Complex shipping logistics for specialized fabrics

- Tariff-related risks in U.S.–China trade

How Can Buyers Overcome Supply Risks?

Buyers should diversify sourcing between China and regional warehouses, supported by customs clearance strategies. Using bonded warehouses in Europe and the U.S. can shorten lead times. Partnering with suppliers who already export to 100+ countries, like Fumao Fabric, ensures trade resilience.

Another solution is leveraging AI-driven trend analysis. Our team uses data-driven forecasting to anticipate which technical fabrics, including magnetocaloric cooling, will trend. A good overview of AI in textiles can be found on Fibre2Fashion.

Are There Pricing and Scalability Barriers?

Yes. Magnetocaloric textiles are more expensive than standard functional fabrics due to rare materials and production complexity. To offset this, buyers can:

- Start with small pilot batches

- Explore blended fabrics (poly-cotton with magnetocaloric coatings)

- Leverage government green subsidies for eco-innovation imports

For guidance, international buyers can refer to U.S. Department of Energy’s resources on efficient materials. In one pilot, U.S. manufacturers received a 12% cost reduction through federal incentives for importing sustainable materials.

How to Build Strong Supplier Partnerships?

Building supplier trust is critical when dealing with cutting-edge materials. Magnetocaloric textiles demand open communication, transparent pricing, and continuous R&D collaboration. Brands like Patagonia and Lululemon have succeeded by co-developing fabrics with suppliers rather than treating them as simple vendors.

What Questions Should Buyers Ask Suppliers?

Buyers should ask suppliers:

- What is the lab testing capacity?

- Can they provide QR-code-based fabric tracking?

- Do they offer bulk production guarantees?

- How do they handle custom packaging and shipping?

By asking these questions, buyers reduce risks of quality inconsistencies. More guidance on this process is shared by Sourcing Journal. An example: a U.S. buyer sourcing technical fabrics saved 18% in defect costs by introducing QR-tracking with their supplier.

How Can Partnerships Drive Innovation?

Partnerships go beyond transactions. Many brands co-develop exclusive textiles with suppliers, ensuring market differentiation. At Fumao, we invest ¥550M into sustainable and innovative fabric development, which lets us deliver 1,000+ new designs annually.

Global collaboration enables buyers to launch innovative cooling products faster while maintaining price competitiveness. A useful read for co-development strategies is on McKinsey’s apparel industry reports. Joint R&D has proven to cut time-to-market by as much as 30% in functional fabric launches.

Conclusion

Magnetocaloric cooling textiles represent the future of sustainable cooling. They combine functionality, innovation, and environmental responsibility. For American buyers like Ron, sourcing these fabrics from trusted suppliers ensures both competitive advantage and compliance with global standards.

If you are ready to co-create your own functional fabrics, our team at Shanghai Fumao is here to help. Please connect with our Business Director Elaine at elaine@fumaoclothing.com to discuss your sourcing needs and explore custom solutions tailored for your market.