The search for chemical protective fabrics is often complicated by technical standards, certification codes, and a wide range of suppliers. Procurement teams in the United States and Europe regularly encounter challenges with documentation accuracy, shipment delays, and non-compliance. These issues create unnecessary risks and financial losses.

The most effective approach to finding EN 13034 Type 4 certified limited chemical spray fabrics is to engage with suppliers who provide valid CE certification, independent test reports, and proven reliability in bulk supply.

A structured overview of where to source these fabrics, how to verify compliance, and why Asian manufacturers remain competitive will clarify the selection process for international buyers.

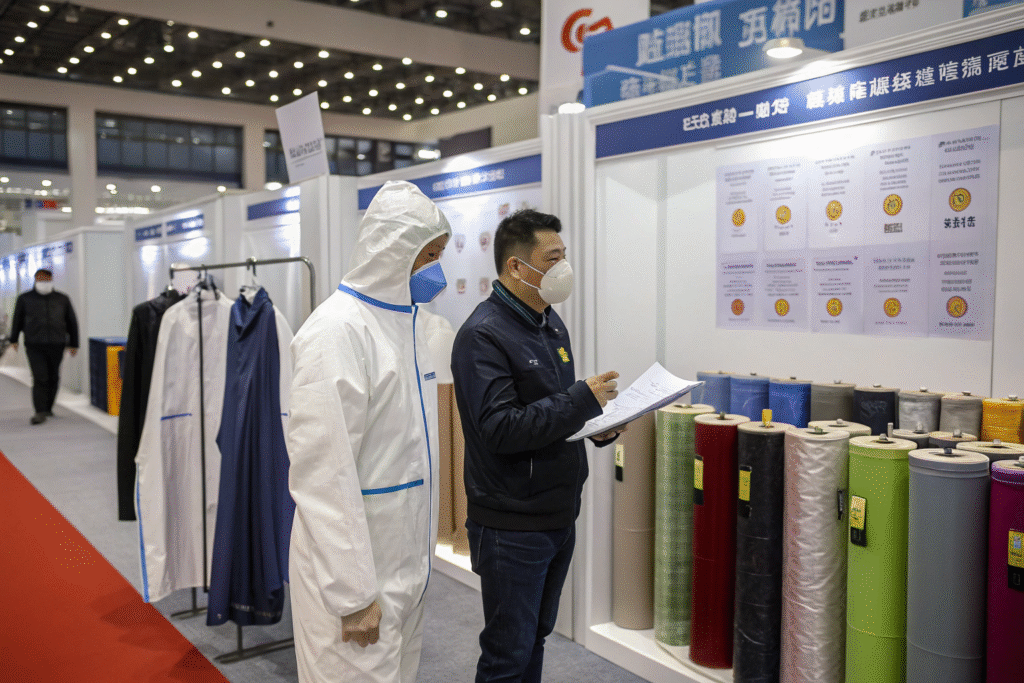

Top Global Sources for EN 13034 Fabrics

Access to certified protective fabrics is not only a matter of cost but also of compliance and timely delivery. For buyers, quality and certification remain the highest priorities.

The primary sources of EN 13034 fabrics include certified Chinese manufacturers, established European protective brands, and specialized PPE producers offering Type 4/5/6 solutions.

Listings on platforms such as Alibaba and Made-in-China often advertise Type 4/5/6 protective clothing. However, due diligence is required. Buyers should ensure that sellers hold genuine EN 13034 certification and can present official test documentation.

What certifications should buyers request from Chinese suppliers?

Chinese manufacturers hold a significant share of the disposable protective fabric market. Certification levels differ. Buyers must confirm that products comply with EN 13034 Type 4 spray-tight protection, as defined under EN 14605 jet-tight protective clothing. Third-party reports from SGS or ITS are essential. These documents must include data on abrasion resistance, seam strength, and chemical repellency.

For reference, buyers may consult Haztec Workwear EN Standards or Huayu Testing Services.

Why do European PPE brands charge higher prices?

European companies such as ULTITEC and ProGARM supply protective garments that extend beyond EN 13034 compliance. They focus on sectors including oil and gas, laboratories, and industrial chemical processing. Higher costs reflect advanced protection features such as flame retardancy and arc resistance. While their reliability is proven, large-volume buyers often select Chinese alternatives for cost efficiency.

Examples include ULTITEC Protective Clothing and ProGARM Standards Overview.

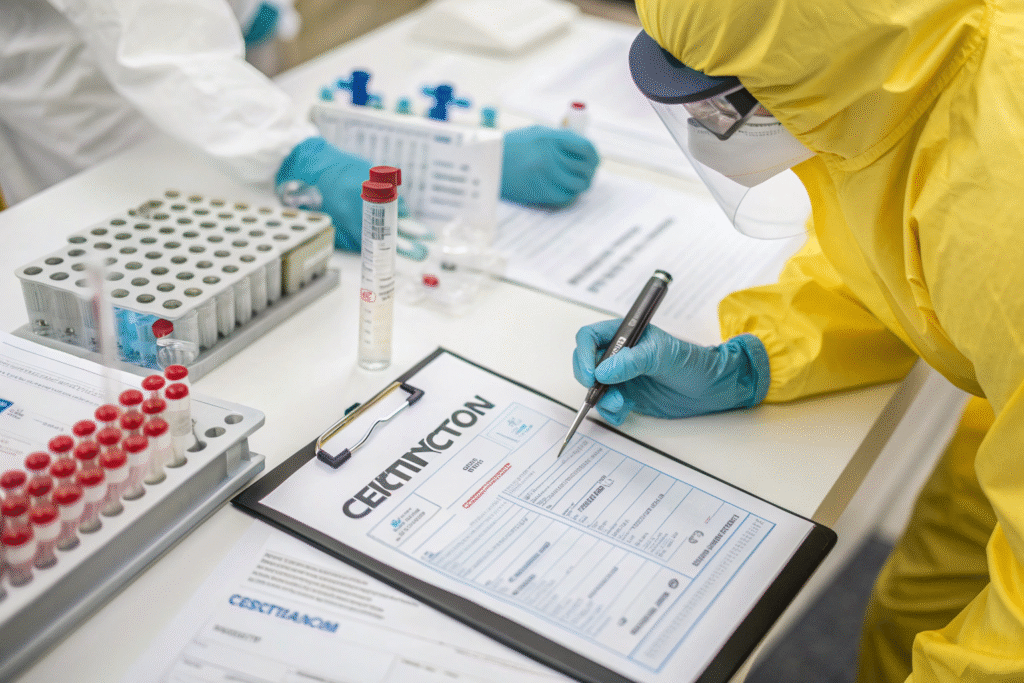

How to Verify EN 13034 Type 4 Certification?

Verification is central to safe procurement. False claims are common in international sourcing, making document review essential.

The correct procedure is to review EN 13034 Type 4 test reports, confirm CE markings, and cross-check with European notified bodies.

EN 13034 defines performance requirements against specific chemicals. Type 4 extends this with jet-tight protection requirements. Suppliers often market garments as Type 4/5/6 combined, but the individual test scope must be clearly identified.

Which documents are essential for buyers?

Buyers should request:

- EN 13034 Type 4 certification issued by an accredited lab.

- EN 14325 physical performance data, including abrasion and tear strength.

- MSDS sheets for fabrics and coatings.

- CE Declaration of Conformity signed by the manufacturer.

If such documents are unavailable, procurement risks increase significantly. For detailed information, consult Hazchem Safety Testing and NDLS Standard Portal.

Are Chinese certificates accepted internationally?

Yes, provided they are issued by laboratories such as SGS, TÜV Rheinland, or ITS. These certificates are valid in both U.S. and EU markets. It is important to verify that the documents state compliance with “EN 13034 Type 4” rather than general chemical splash resistance.

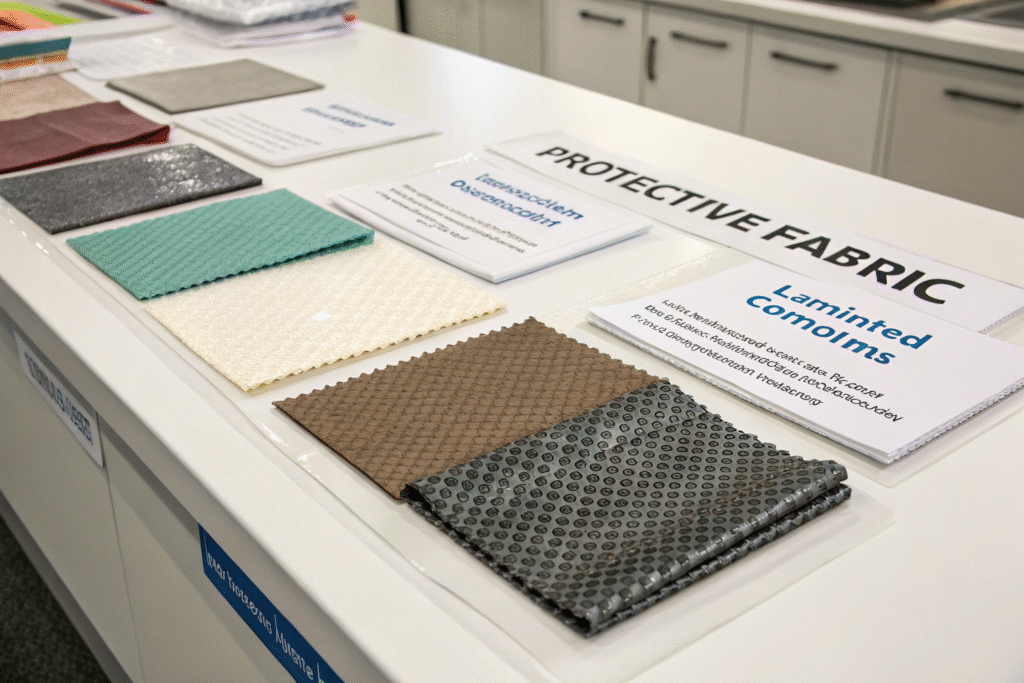

Which Fabrics Are Used for Type 4 Protection?

Fabric selection determines compliance and usability. Certain structures and coatings are necessary to meet performance thresholds.

The main materials for EN 13034 Type 4 protection include microporous film laminates, SMS (spunbond-meltblown-spunbond) composites, and polyurethane-coated woven textiles.

Each option provides different levels of repellency, strength, and breathability. Buyers must balance these characteristics against intended application and budget.

Why are microporous laminates commonly selected?

Microporous laminates combine nonwoven backings with breathable films. They block liquid penetration while allowing vapor transfer, which supports longer use. These are widely applied in disposable protective garments. Suppliers such as Wanli Protective Clothing and Made-in-China PPE Listings offer bulk solutions.

Can woven fabrics with PU coatings meet requirements?

Yes. PU-coated polyester or nylon fabrics, when combined with taped seams, achieve Type 4 protection. These are heavier, reusable garments designed for long-term use. They are more costly but deliver higher durability. Buyers can review Oxwork Chemical PPE or Granite Workwear EN 13034 Listings for examples.

How to Choose the Right Supplier for Bulk Orders?

Supplier selection influences compliance, logistics, and financial security. For international buyers, consistency is as important as certification.

The ideal supplier provides certified EN 13034 Type 4 fabrics, predictable shipping schedules, and financial strength to manage large-scale contracts.

Delays caused by tariffs, weak packaging, or limited logistics capacity affect buyer confidence. Integrated suppliers with control over weaving, coating, inspection, and packaging ensure more reliable outcomes.

Which negotiation points are critical?

- Transparent pricing with full cost breakdowns.

- Flexible MOQs to support trial orders.

- Durable packaging to prevent contamination.

- Global logistics capacity with multimodal shipping options.

Buyers may explore Alibaba Fabric Listings or Global Sources PPE Options.

Why collaborate with Shanghai Fumao?

Shanghai Fumao integrates weaving, coating, embroidery, printing, and packaging within a single supply chain. Our CNAS-accredited laboratory performs batch testing, while digital QR codes provide clients with real-time quality data. This system reduces compliance risks and ensures consistent delivery for buyers in the U.S. and Europe.

Conclusion

Identifying EN 13034 Type 4 certified protective fabrics requires careful evaluation of certification, fabric structure, and supplier reliability. Microporous laminates and PU-coated woven fabrics are the most common options. Successful sourcing depends on requesting valid test documentation and selecting suppliers with integrated operations.

Buyers seeking dependable supply chains and certified protective fabrics are invited to contact Shanghai Fumao. With over two decades of textile expertise, we deliver end-to-end solutions for global clients. For inquiries, please reach out to our Business Director Elaine at elaine@fumaoclothing.com.

Recraft指令--Business meeting between a professional textile supplier and overseas clients, shaking hands in a bright office with protective fabric rolls visible. Emphasis on cooperation and trust, realistic faces, global trade context.