As sustainability becomes the biggest driver of innovation in fashion and technology, many businesses are asking the same question: can we combine electronics with fabrics in a way that is still safe for the planet? Traditional e-textiles often rely on plastics, metals, and synthetic fibers that cause e-waste after use. For brands, buyers, and manufacturers who want both smart functionality and eco-friendly solutions, this creates a painful challenge.

The latest biodegradable electronics-integrated textiles offer a clear solution. New research and industrial developments show how natural fibers like Tencel™, silk, and cellulose can be combined with conductive polymers, graphene, or plant-based biomaterials to create fabrics that are smart, flexible, and compostable. These innovations open doors for fashion, healthcare, and sports industries to use smart textiles without leaving behind harmful waste.

For sourcing teams, designers, and entrepreneurs, these breakthroughs signal a major shift. Instead of worrying about long-term waste, tariffs, or compliance with strict U.S. and European regulations, businesses can now explore functional fabrics that monitor health, respond to touch, and integrate with AI while still decomposing naturally. In the following sections, I will share the most relevant developments you need to know.

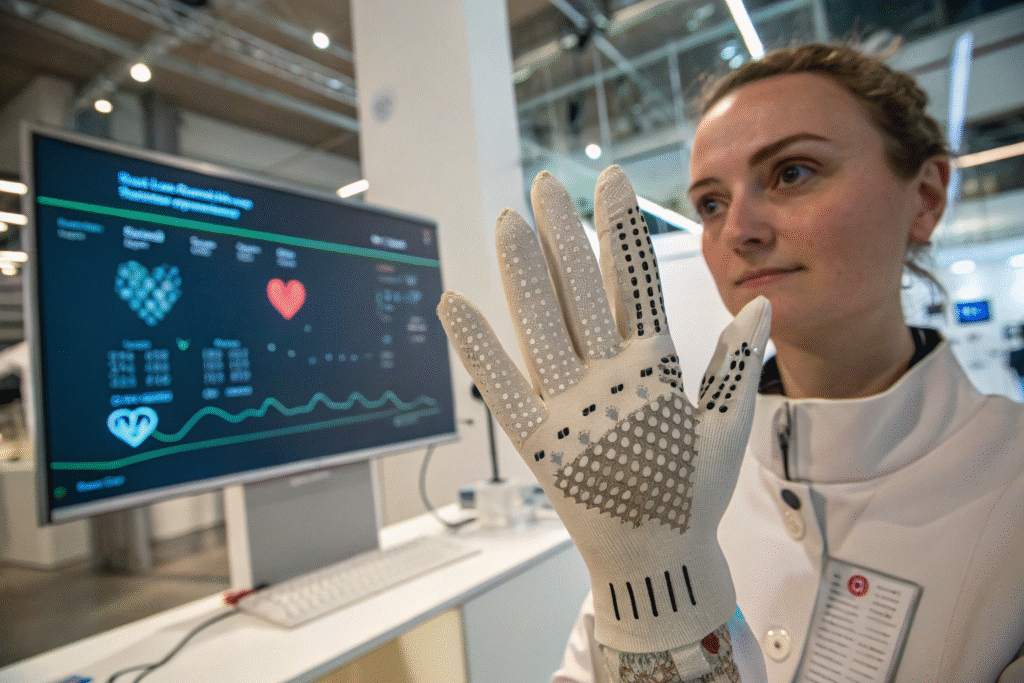

SWEET Smart Textiles for Wearable Health Monitoring

The demand for wearables that can monitor health data is rising in the U.S. and Europe, but most products generate electronic waste. This problem frustrates buyers who want innovation but also need to satisfy eco-conscious consumers.

The SWEET project, developed in the UK, solves this problem with fully inkjet-printed biodegradable smart textiles. These fabrics use a Tencel™ base, layered with graphene and PEDOT:PSS, to create sensors that can monitor heart rate and body temperature. After four months in soil, the textiles degrade by 50%, leaving almost no environmental footprint.

By combining natural fibers with advanced printing, SWEET proves that it is possible to merge performance with biodegradability. This technology offers global buyers confidence in both function and sustainability.

How do these textiles reduce medical e-waste?

SWEET fabrics were tested as biomedical sensors and proved capable of reliable real-time health tracking. Compared to traditional devices, which often use plastics and non-degradable metals, SWEET integrates fully compostable layers. This reduces e-waste in medical wearables, especially for temporary or disposable devices. Industry experts point out that healthcare systems across Europe and the U.S. are actively searching for such eco-conscious solutions.

Can biodegradable fabrics compete with synthetic e-textiles?

Yes, because these fabrics retain performance during their use-phase. Research published on Good News Network shows that they can withstand daily wear while providing data accuracy similar to synthetic-based e-textiles. This means U.S. and European buyers no longer need to compromise between functionality and eco-regulations when sourcing fabrics.

Biodegradable Conductive Fibers for Wearables

Many entrepreneurs in the sportswear and lifestyle sectors face problems sourcing sustainable conductive materials. Traditional conductive yarns contain metals or petroleum-based fibers, which conflict with green compliance standards in the EU and U.S.

Researchers at Seoul National University developed biodegradable conductive fibers that solve this pain point. These fibers, spun from natural polymers combined with conductive additives, can completely degrade after their lifecycle, avoiding landfill waste.

This innovation allows businesses to design wearables—from yoga shirts to jackets—that integrate electronics but still comply with strict sustainability standards.

What advantages do these fibers offer to global brands?

These fibers provide the same conductivity as synthetic alternatives but decompose naturally. According to TechXplore research, they also deliver strong mechanical durability, meaning they can withstand stretching during sports activities. For brands in the U.S. and Europe, this offers a marketing edge: smart apparel that is high-performance and sustainable.

How do biodegradable fibers improve sourcing strategies?

Buyers benefit from easier compliance with green certifications like OEKO-TEX and REACH, since biodegradable components align with these frameworks. By sourcing such fibers, companies can avoid tariffs or rejection from eco-regulated markets. For further reference, OEKO-TEX’s official site outlines how certified eco-fabrics streamline export processes.

Silk Fibroin Ionic Touchscreens and Smart Interfaces

In fashion and consumer tech, the dream of interactive clothing often clashes with sustainability requirements. Conventional touch panels are made with plastics and glass, which are unsuitable for integration with eco-textiles.

Chinese researchers introduced silk fibroin-based ionic touchscreens that are flexible, biodegradable, and smart. These fabrics integrate AI and IoT, allowing for gesture control, handwriting recognition, and interactive human-computer systems.

This technology makes possible a new category of interactive clothing that is safe for the environment and attractive to eco-conscious buyers.

How can silk-based e-textiles be applied in fashion?

Silk fibroin touchscreens can be integrated into wearable technology for jackets, handbags, or accessories. They allow users to interact with their phones or smart home devices without separate gadgets. The eco-friendly base of silk ensures these fabrics biodegrade naturally after use.

Are silk fibroin materials stable enough for real-world use?

Yes, studies from ShanghaiTech University confirm that silk fibroin composites maintain stability under normal environmental conditions while still breaking down safely in controlled disposal. This balance makes them highly suitable for consumer markets, where buyers want reliable use but no environmental burden.

Eco-Threads and Compostable Interactive Biomaterials

In the U.S. and European markets, small-batch innovators often ask for customizable eco-smart textiles. The challenge is balancing innovation, scalability, and biodegradability.

Cornell University introduced Eco-Threads—biodegradable e-textile prototypes like pH-sensing undergarments, touch sensors, and gel patches. At the same time, other global teams are creating compostable biomaterials from plants and algae that encode tactile information without microchips.

These approaches show that sustainable e-textiles can go beyond wearables and become part of everyday consumer products.

Can Eco-Threads be scaled for commercial production?

Yes, since Eco-Threads use wet-spinning and coating methods compatible with existing textile production lines. Details on biodegradable electronics confirm that carbon nanotubes, silver nanowires, and PEDOT:PSS can be adapted into scalable supply chains. This means U.S. and European buyers can pilot small batches and then expand orders without redesigning entire factories.

How do compostable biomaterials create interaction without chips?

Research published on arXiv shows that plant-based biomaterials like chlorella and magnetite can encode tactile responses into fabric structure. These materials decompose fully in 21 days, making them perfect for short-use applications like packaging or temporary fashion displays. Buyers benefit from interactive features without the burden of electronic waste.

Conclusion

Biodegradable electronics-integrated textiles are no longer futuristic concepts. From the SWEET project in the UK to silk fibroin touchscreens in China, from Seoul’s biodegradable fibers to Cornell’s Eco-Threads, these innovations prove that smart fabrics can also be eco-conscious. For global buyers, this means sourcing fabrics that satisfy both consumer demand for performance and regulatory requirements for sustainability.

If you are ready to bring these breakthroughs into your own supply chain, we at Shanghai Fumao can support you with development, customization, and export solutions. To co-create your own biodegradable textile orders, please reach out to our Business Director Elaine at elaine@fumaoclothing.com.