In high-risk industries, one mistake in protective gear can mean the difference between life and death. Many professionals working in hazardous environments worry about exposure to toxic chemicals, biological threats, or extreme weather conditions. Without the right fabric technology, protective suits may fail to safeguard workers against invisible dangers. Because of these risks, companies cannot compromise on the quality of protective fabrics.

SCAPE suit fabrics are designed to provide maximum protection in environments where breathable air is unsafe. These fabrics combine advanced material science with multi-layer barrier construction to block chemical, biological, radiological, and nuclear (CBRN) agents while ensuring durability and comfort. As a result, they serve as the last line of defense in situations where failure is not an option.

Unlike ordinary protective clothing, SCAPE fabrics are engineered for mission-critical scenarios. They are not just garments; they are lifelines. Therefore, understanding their benefits can help decision-makers in defense, emergency response, and hazardous industries make smarter, safer choices.

Key Benefits of SCAPE Suit Fabrics

In industries facing dangerous atmospheres, protective fabrics must deliver more than a physical shield. When safety, efficiency, and cost control are at stake, decision-makers demand solutions that address all three factors together.

The primary benefits of SCAPE suit fabrics include exceptional chemical resistance, extended wear comfort, and long-term durability. Because of this balance, they are indispensable in sectors where exposure to hazardous atmospheres is routine.

SCAPE fabrics undergo rigorous laboratory testing to meet global standards. Over time, this testing ensures consistent performance when workers face unpredictable threats in the field, reinforcing trust in the equipment they wear.

What makes SCAPE fabrics resistant to chemicals?

SCAPE fabrics use multi-layer membranes that block gases, vapors, and liquids. Materials like fluoropolymers and advanced laminates are combined to withstand corrosive acids, industrial solvents, and warfare agents. As a result, these designs prevent penetration while maintaining flexibility. Independent testing by organizations such as ASTM International verifies their chemical resistance, which strengthens buyer confidence.

How do SCAPE suits ensure long-term durability?

Durability comes from reinforced seams, abrasion-resistant outer layers, and engineered coatings. SCAPE fabrics are designed to survive repeated exposure to harsh conditions without losing integrity. Unlike standard coveralls, these suits retain protective qualities after extended wear. Research published by NIOSH supports the need for reinforced protective fabrics in high-risk industries. Consequently, buyers value this durability because it reduces replacement costs while maximizing safety.

Because SCAPE fabrics integrate both resistance and longevity, they ensure reliability in critical missions and reduce long-term operational risks.

Comfort and Ergonomics in Protective Gear

Although protection is the first priority, comfort and ergonomics play an equally vital role. If workers cannot perform their tasks effectively, safety is compromised in another way.

SCAPE fabrics integrate breathability, reduced weight, and ergonomic flexibility to ensure workers stay agile without overheating. Because of these improvements, fatigue is reduced and performance is enhanced during critical missions.

Unlike outdated bulky suits, modern SCAPE fabrics allow professionals to move naturally while staying shielded from environmental hazards. As a result, organizations achieve both safety and efficiency.

Why is breathability critical in SCAPE suits?

Breathability prevents heat stress, one of the biggest risks during long missions. SCAPE fabrics use microporous membranes that let water vapor escape while blocking hazardous agents. Studies by OSHA stress the importance of thermal comfort in protective equipment. Therefore, breathable fabrics ensure workers remain focused and operational, even in extreme environments.

Do SCAPE fabrics support ergonomic mobility?

Yes. Fabrics are engineered with stretch zones and lightweight composites. This allows wearers to crawl, run, or handle tools without restrictions. Ergonomic testing by DuPont Personal Protection shows that mobility enhances safety by reducing accidents caused by stiffness or fatigue. For industries requiring fast response, this mobility becomes as vital as chemical protection.

By combining safety with wearability, SCAPE fabrics enable sustained performance, which directly improves mission success rates.

Applications Across Industries

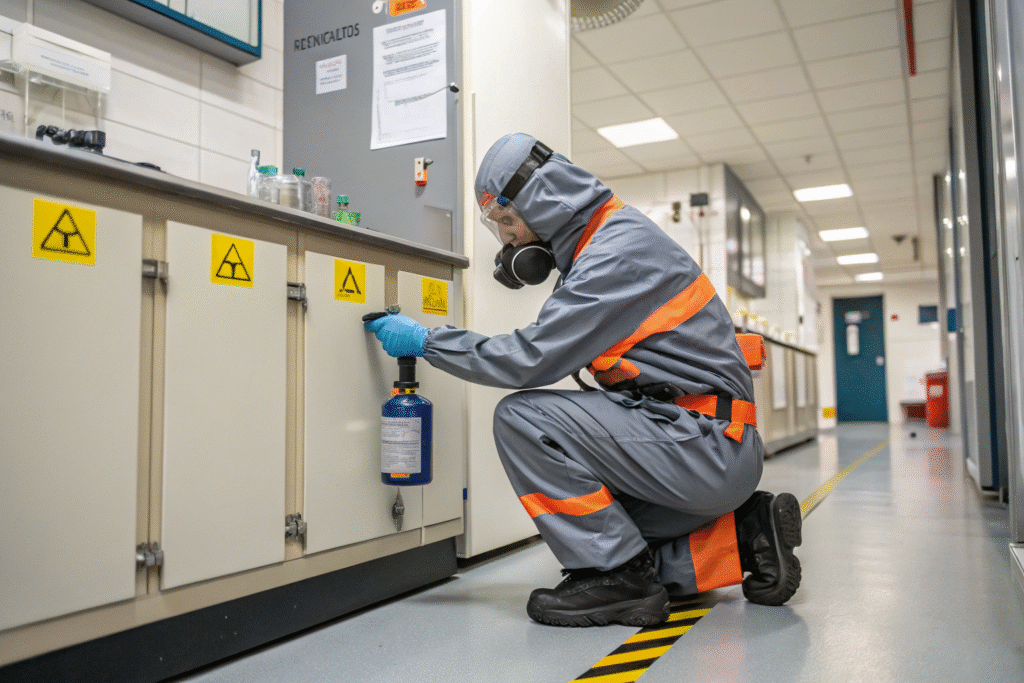

Because exposure to hazardous environments is not limited to one sector, SCAPE fabrics are versatile across industries. From routine factory operations to emergency situations, they adapt to the level of protection required.

Industries such as petrochemical, pharmaceuticals, mining, and aerospace rely on SCAPE fabrics for hazardous material handling and confined-space operations. Consequently, their adaptability makes them a universal safety solution.

Choosing SCAPE fabrics means ensuring a safer workplace wherever toxic exposure risks exist. Over time, this reliability builds a culture of trust and safety across organizations.

Which industries benefit most from SCAPE fabrics?

Petrochemical plants use them for protection from toxic vapors. Pharmaceutical industries apply them to avoid contamination during drug manufacturing. Aerospace relies on SCAPE suits for fuel handling and spacecraft maintenance. According to American Chemical Society, barrier fabrics significantly reduce occupational exposure risks. Energy.gov also highlights the importance of advanced suits for nuclear and chemical handling.

Are SCAPE suits suitable for emergency responders?

Absolutely. Firefighters, hazmat teams, and military units use SCAPE suits to enter hazardous zones safely. Their quick deployment and integrated life-support systems make them ideal for first-response missions. Reports from FEMA and Homeland Security confirm that SCAPE fabrics are essential in disaster management and biohazard response.

Because SCAPE suits address the needs of both industrial and emergency sectors, they are trusted as a cross-industry safety investment.

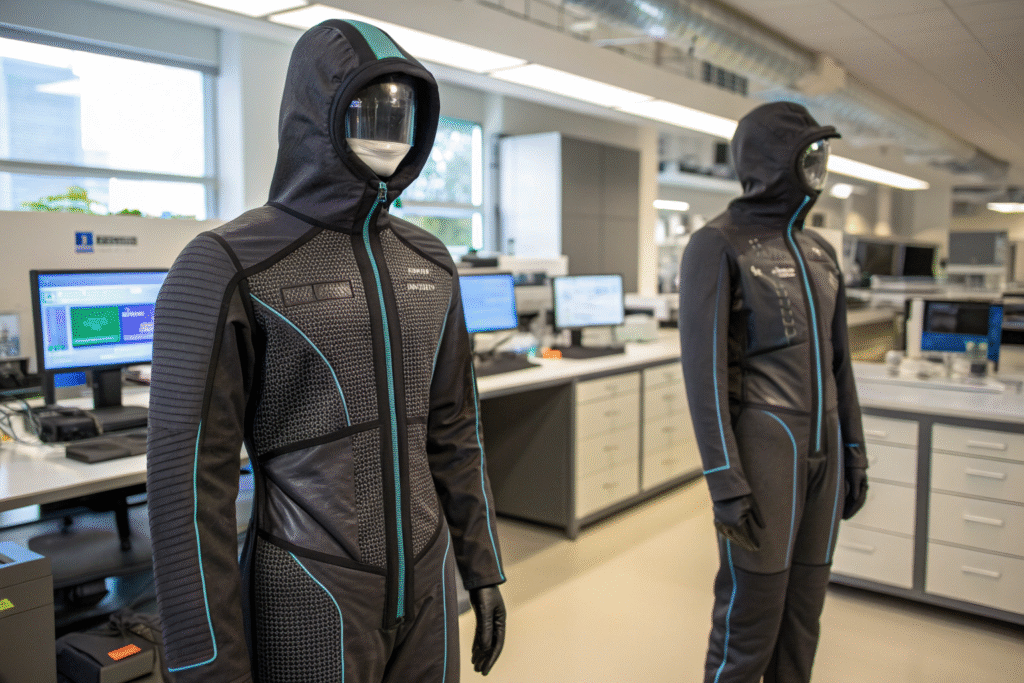

The Future of SCAPE Suit Fabrics

Over time, protective fabric technology has continuously improved. Today, SCAPE fabrics are at the forefront of this progress, and tomorrow they will transform even further.

Innovations such as nanotechnology coatings, self-healing membranes, and biodegradable barriers are shaping the next generation of SCAPE suits. As a result, these advancements will enhance protection while reducing environmental impact.

Forward-looking companies are already investing in research to make SCAPE fabrics smarter, lighter, and more sustainable. This shift is not just about safety; it is also about responsibility toward the environment.

What new technologies are being developed?

Nanotechnology improves resistance at the molecular level, while self-healing fabrics repair micro-tears automatically. Some research even explores fabrics that change color when exposed to toxins. According to Nature Materials, these innovations could redefine protective clothing. MIT’s research on advanced membranes is paving the way for future SCAPE designs.

How will sustainability shape SCAPE fabrics?

The industry is moving toward biodegradable and recyclable protective fabrics. This helps reduce waste from disposable suits. Organizations such as Textile Exchange promote sustainability in high-performance textiles. World Resources Institute also stresses the need for eco-friendly innovations in industrial safety equipment. As a result, SCAPE fabrics of the future will protect both workers and the planet.

Because of these innovations, SCAPE fabrics will continue to lead the protective textile market and align with global sustainability goals.

Conclusion

SCAPE suit fabrics combine protection, comfort, and innovation. They are the foundation of safety in environments where breathable air is unsafe. From chemical plants to emergency zones, these fabrics protect workers and enable them to perform at their best. With new technologies on the horizon, SCAPE fabrics are set to become even more reliable and sustainable. Because of these factors, choosing SCAPE fabrics today means investing in both present safety and future progress.

If you are looking to partner with a trusted fabric manufacturer for protective textiles or any custom solutions, reach out to us at Shanghai Fumao. Our Business Director, Elaine, can guide you through every step of your order. Contact her directly at elaine@fumaoclothing.com to start building your protective fabric solutions today.