In space exploration, every gram and every centimeter matter. Engineers consistently face the challenge of how to design antennas that can fold compactly for launch and then expand into large, precise structures in orbit. If the wrong fabric is chosen, the result can be distortion, signal loss, or even mission failure. Buyers, suppliers, and aerospace innovators therefore pay close attention to which fabrics deliver the right balance of weight, flexibility, durability, and precision.

The best fabrics for satellite deployable antennas are metallized meshes, high-performance polymer membranes, triaxially woven composites, and shape-memory polymers. These materials combine low mass with strength, high reflectivity, and the ability to withstand extreme conditions. Because each fabric type offers different advantages and trade-offs, engineers select them according to mission frequency, size, and cost.

The choice of antenna fabric directly determines not only performance but also reliability in orbit. Since satellites must survive the vacuum of space, intense radiation, and sharp thermal cycles, the fabric must be both durable and adaptable. To understand this better, let’s explore the leading materials in sequence and examine why they stand out.

Why Use Metallized Mesh Fabrics?

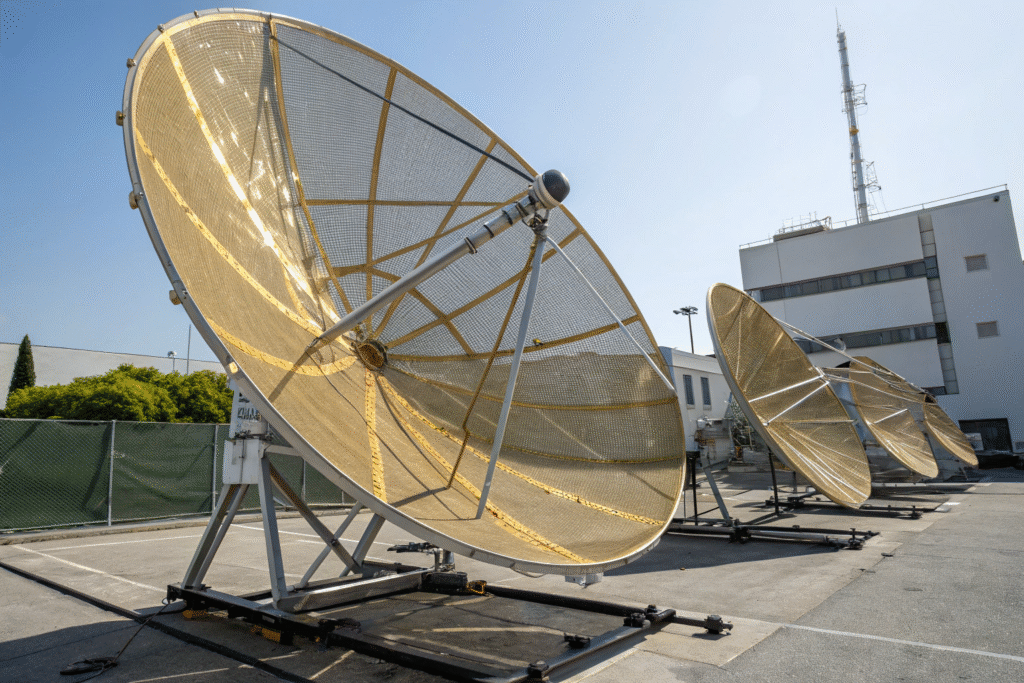

Because metallized mesh fabrics have already proven themselves in decades of missions, they remain the first choice for many large space antennas. Engineers rely on them for their ability to balance low weight with excellent RF reflectivity.

Metallized mesh fabrics, particularly gold- or silver-coated Dacron and molybdenum wire meshes, are widely used for large space antennas due to their RF efficiency and lightweight structure. When engineers stretch these meshes across deployable frames, they create parabolic surfaces with minimal mass. Consequently, these meshes are ideal for large reflectors on communication and Earth-observing satellites.

As the required frequency increases, the precision demand grows. At lower bands, meshes perform well even with minor surface deviations. However, at Ka-band and higher, engineers must maintain extremely tight tolerances to avoid performance loss.

How Do Mesh Fabrics Improve Signal Performance?

Mesh reflectors function by stretching metallic fibers into parabolic shapes that reflect electromagnetic waves. Since the mesh allows tiny amounts of light and heat to pass through, it reduces thermal stress. For example, NASA’s ATS-6 mission used a 9-meter gold-plated molybdenum mesh successfully (NASA Technical Reports). Later, JAXA followed with molybdenum mesh reflectors for the ETS-VIII program (JAXA ETS-VIII Overview).

What Are the Limitations of Mesh Fabrics?

However, mesh fabrics require continuous tensioning to keep their accuracy. Any slack reduces gain and distorts the signal. For high-frequency missions, this becomes a limiting factor. Agencies like ESA often invest in calibration systems to ensure in-orbit accuracy. Although this increases cost, the proven reliability of mesh reflectors often justifies the expense for large missions.

Are Polymer Membrane Films Effective?

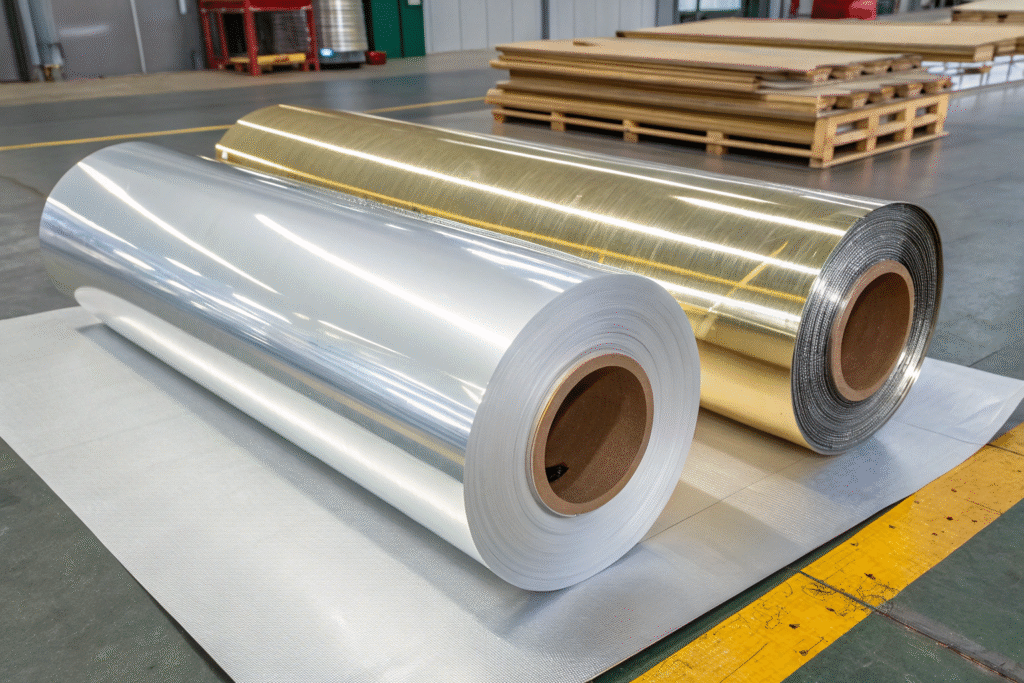

Because compact storage and lightweight design are critical for smaller satellites, polymer membranes have become increasingly attractive. Their thinness allows engineers to fold them tightly and still deploy large surfaces in orbit.

Polyimide and polyester films, often coated with aluminum or silver, are ideal for membrane antennas where ultra-light mass and compact stowage are essential. When tensioned, these films form reflective surfaces that enable large apertures without adding much weight.

These membranes are particularly useful for CubeSats and microsatellites, where payload mass and cost are highly constrained.

How Do Polymer Membranes Work in Space?

Membrane films such as Kapton and Mylar can be folded before launch and later inflated or tensioned in orbit. Their metallized coatings provide high reflectivity, while their flexibility makes them easy to deploy. A study in the Chinese Journal of Mechanical Engineering confirmed that aluminized polyester membranes maintain strength and reflectivity under space-like conditions (SpringerOpen CJME).

What Are the Challenges of Membrane Antennas?

Yet membranes face two key risks: surface irregularities and punctures. Because their performance depends on tension, even slight sagging can reduce gain at high frequencies. In addition, micrometeoroid punctures can cause damage. To address this, engineers use laminates or self-healing coatings. Agencies such as ESA are actively testing advanced textiles to make membranes more resilient.

Why Are Woven Composite Fabrics a Breakthrough?

As missions require higher precision and performance, engineers have turned to woven composite fabrics. These new materials combine flexibility with structural integrity.

Triaxially woven fabric-reinforced silicone (TWFS) composites enable antennas to fold compactly while still deploying into precise curved reflectors. Because they distribute stress equally in three directions, they offer isotropic strength that traditional composites lack.

![]()

This breakthrough makes them especially useful for Ka-band and higher, where surface accuracy directly determines efficiency.

How Do Woven Composites Ensure Surface Precision?

Unlike traditional woven fabrics, TWFS composites distribute loads evenly. As a result, they maintain their shape better under stress. A study published in MDPI Aerospace demonstrated that TWFS composites can achieve high precision while remaining lightweight (MDPI Aerospace Study).

Are There Drawbacks to Composite Fabrics?

Nevertheless, woven composites are more complex to manufacture. Producing large, seamless, and uniform surfaces requires specialized technology, which raises costs. Even so, for missions demanding both compact stowage and high-frequency accuracy, these composites represent a superior solution. Commercial satellite constellations, which rely heavily on data throughput, are now testing these fabrics.

Can Shape-Memory Polymers Transform Antenna Deployment?

As satellites shrink and mission budgets tighten, engineers seek simpler deployment mechanisms. Shape-memory polymers (SMPs) have emerged as a solution that reduces mechanical complexity.

Shape-memory polymers can be folded into compact forms and then activated by heat to restore their original shapes. This eliminates the need for heavy deployment actuators and provides a reliable way to build lightweight antennas.

SMP-based reflectors are particularly attractive for small satellites, where every gram counts.

How Do Shape-Memory Polymers Deploy Antennas?

SMPs are “programmed” with a target shape. During launch, they are compressed and stowed. After reaching orbit, exposure to solar heat or onboard heaters triggers their recovery. For example, Composite Technology Development has successfully demonstrated deployable SMP structures.

What Are the Risks of Using SMPs?

However, SMPs depend on precise thermal activation. If exposed to incorrect temperatures, they may deploy prematurely or degrade over time. To improve durability, researchers combine SMPs with carbon-fiber reinforcements. According to NASA, ongoing tests are refining these hybrids for future missions.

Conclusion

The development of satellite deployable antennas depends on fabrics that balance low mass, strength, and precision. Metallized meshes remain the most reliable for large reflectors, while polymer membranes offer affordable compactness for smaller missions. Woven composites provide high-frequency accuracy, and shape-memory polymers open new possibilities for smart, simplified deployment.

Because each fabric type has distinct advantages and limitations, the best choice always depends on mission requirements. When precision is critical, woven composites excel. When budget and mass are priorities, polymer membranes are effective. When innovation is desired, shape-memory polymers lead the way. In every case, the material defines the antenna’s success in orbit.

If you want to co-develop or source advanced fabric solutions for aerospace and satellite applications, our team at Shanghai Fumao is ready to support you. Contact our Business Director Elaine at elaine@fumaoclothing.com to explore custom developments and production partnerships tailored to your mission.